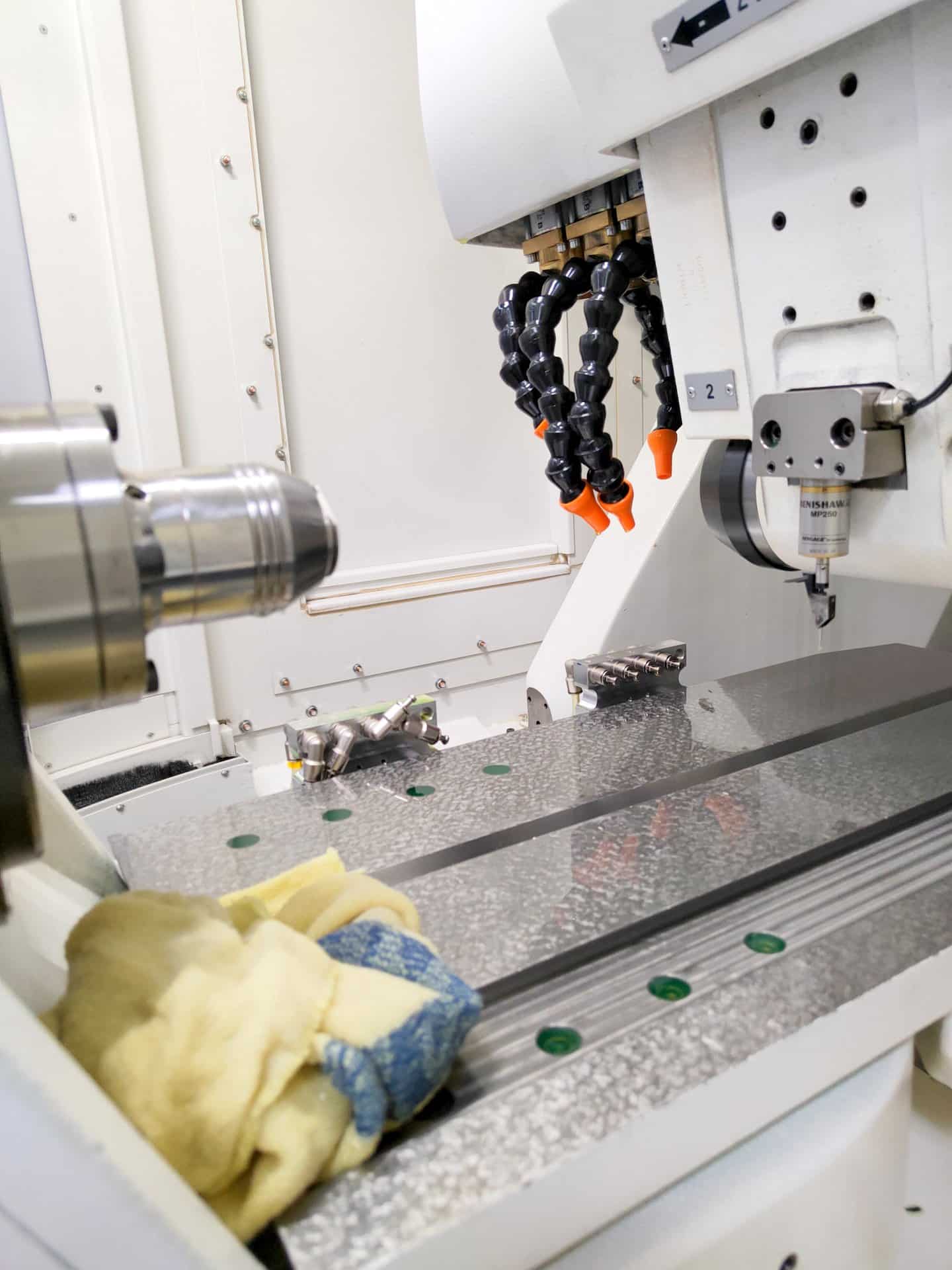

WALTER HELITRONIC POWER 400 CNC grinding machine built in 2017 in Germany, is designed for fully automatic tool grinding. The grinding process takes place in five axes (X,Y,Z,C,A), on workpieces with a maximum length of 380 mm (end face grinding) or 520 mm (peripheral grinding) and with a weight up to 50 kg. Axis feeds are respectively 650 mm (X axis), 350 mm (Y axis), 720 mm (Z axis), 400° (C axis) and ∞° (A axis).

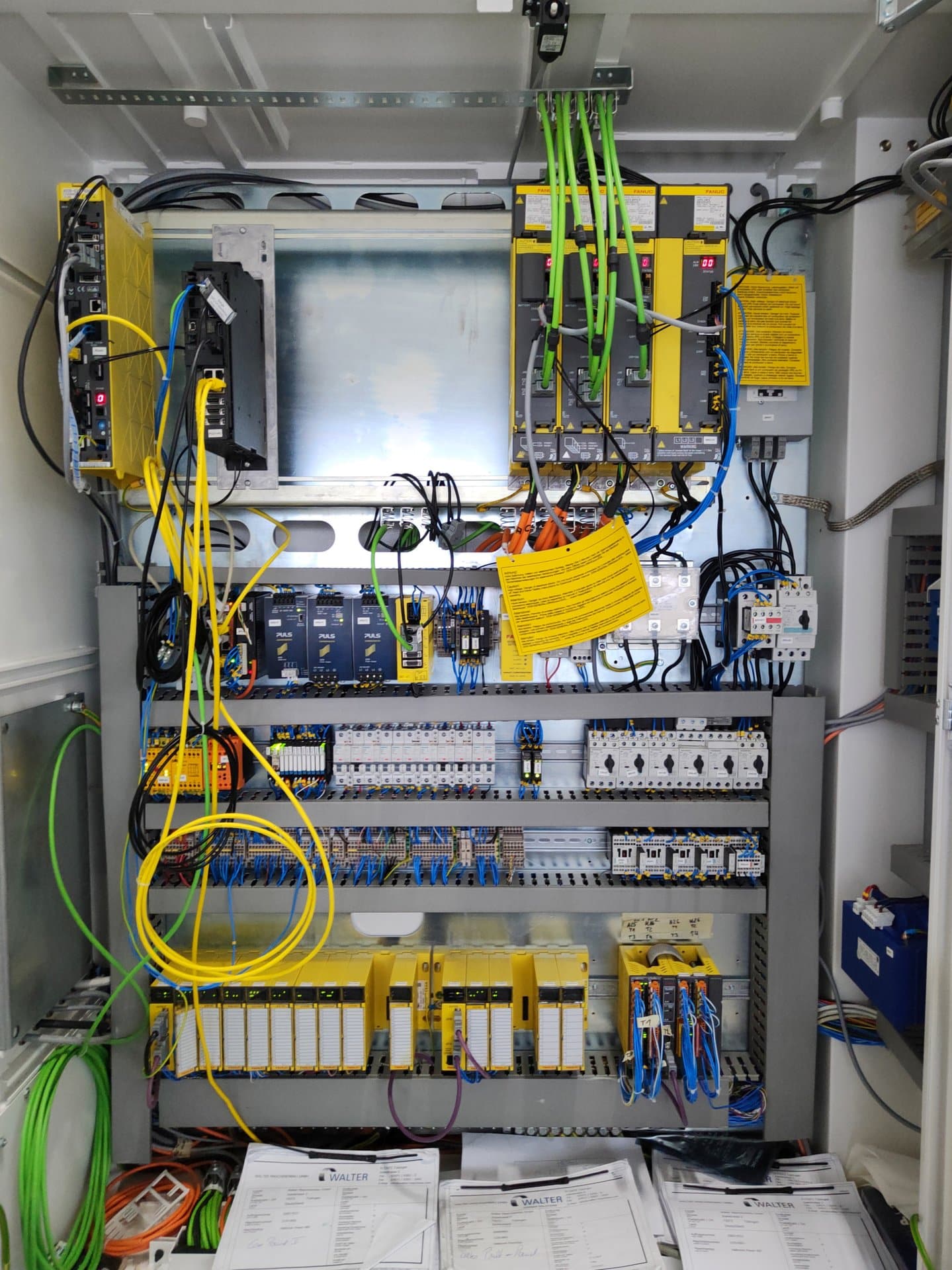

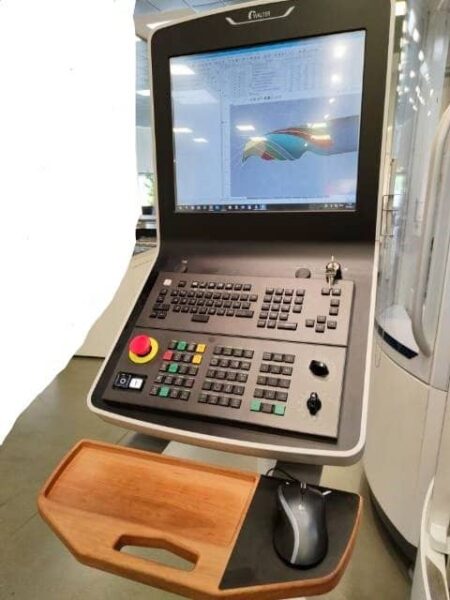

Superior machining quality and precision is achieved thanks to the machine’s solid grey cast iron construction with increased rigidity, effectively reducing vibrations during the grinding process. The modern design and installed high-end FANUC CNC controller with a large and comfortable to use control panel, significantly distinguishes the grinding machine from the rest of the machines in its class.

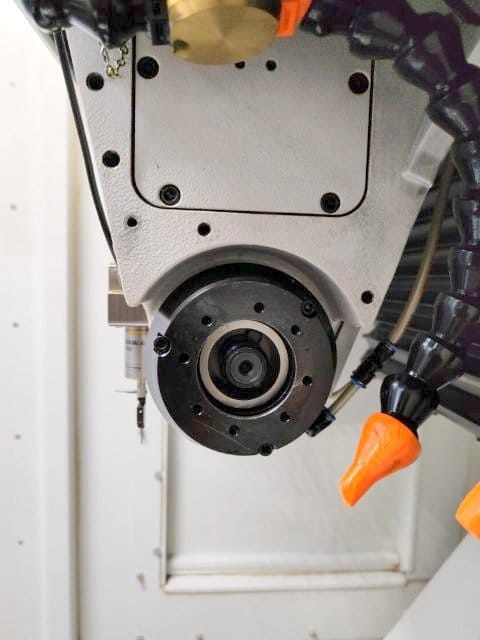

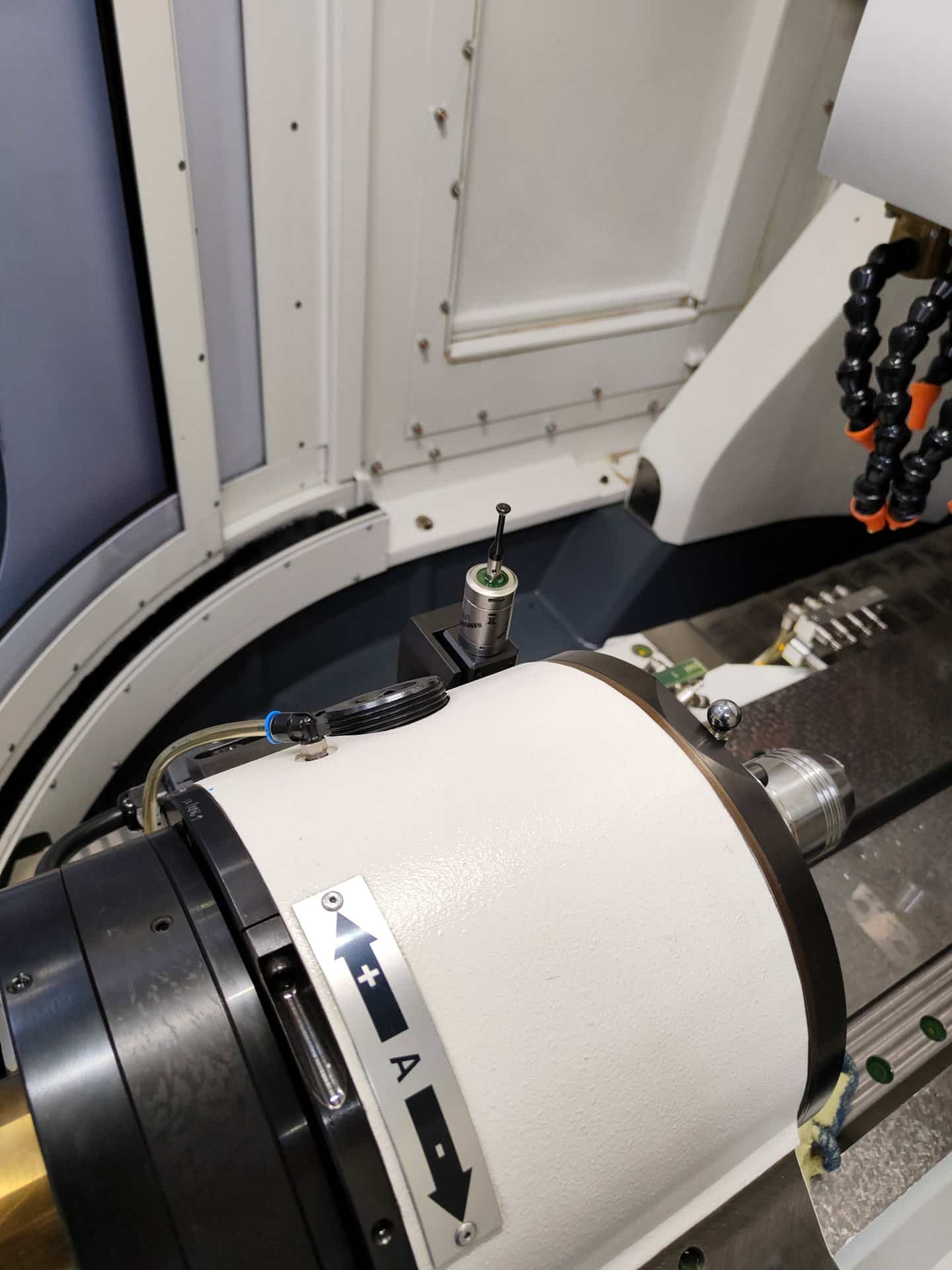

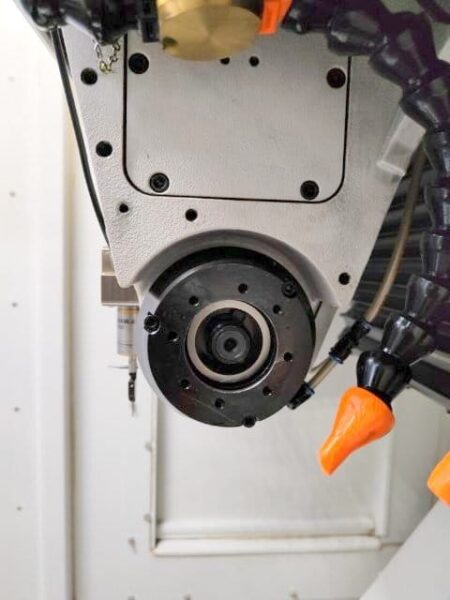

The extensive equipment of the CNC grinding machine include among others the RENISHAW MP250 electrostatic probe performing reliable measurements in all conditions, a spindle operating at a maximum speed of 10500 rpm and the CAD/CAM software HELITRONIC TOOL STUDIO for designing and editing all tool parameters. The five-axis CNC grinding machine weighs approximately 5300 kg.

Technical specification of the WALTER HELITRONIC POWER 400 CNC grinding machine

- 5 axes (X,Y,Z,C,A)

- maximum feed rates in the X/Y/Z axes: 650/350/720 mm

- feed rate in rotary axis C: 400°

- feed rate in rotary axis A: ∞°

- maximum rapid feed rates in the X,Y,Z axis: 15 m/min

- minimum tool diameter: 3 mm

- maximum tool diameter: 315 mm

- maximum length of ground workpiece (peripheral grinding): 520 mm

- maximum length of ground workpiece (end face grinding): 380 mm

- maximum weight of ground workpiece: 50 kg

- accuracy of spatial positioning in axes: 0.0001 mm

- accuracy of spatial positioning in rotary axes: 0.0001°

- maximum diameter of grinding wheel: 254 mm

- spindle speed range: 0-10500 rpm

- spindle diameter: 80 mm

- spindle power: 24 kW

- electrostatic probe diameter: 25 mm

- spindle operating hours: 1200 h

- hours of connection to electricity: approx. 9000 h

- total power requirement: approx. 25 kVA

- dimensions of the POWER 400 machine (L x W x H): 2700 x 1691 x 2640 mm

- weight: approx. 5300 kg

Equipment for the CNC grinding machine

- CNC controller: FANUC

- CAD/CAM software HELITRONIC TOOL STUDIO

- electrostatic probe: RENISHAW MP250

- tool holder: HSK 50

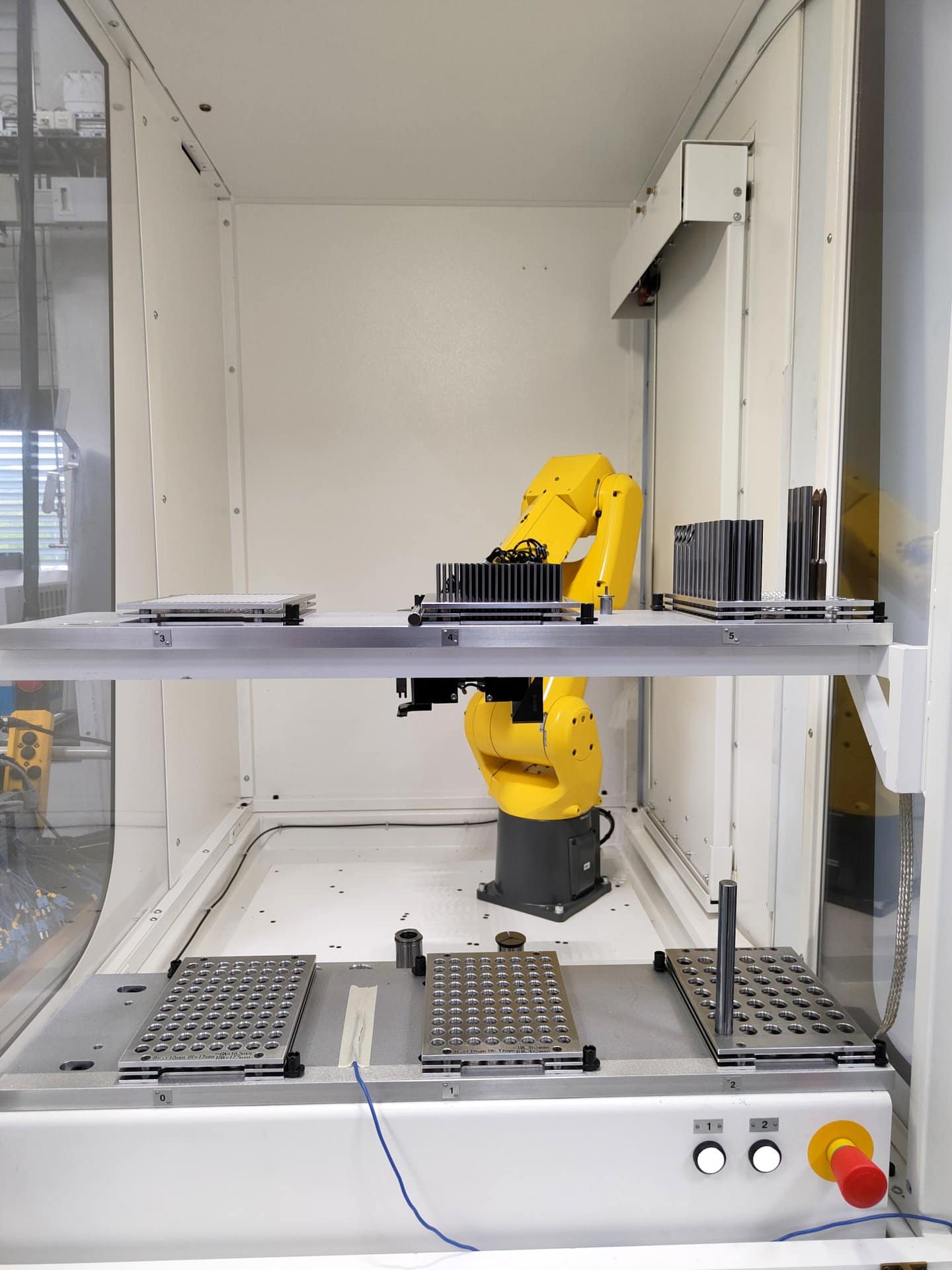

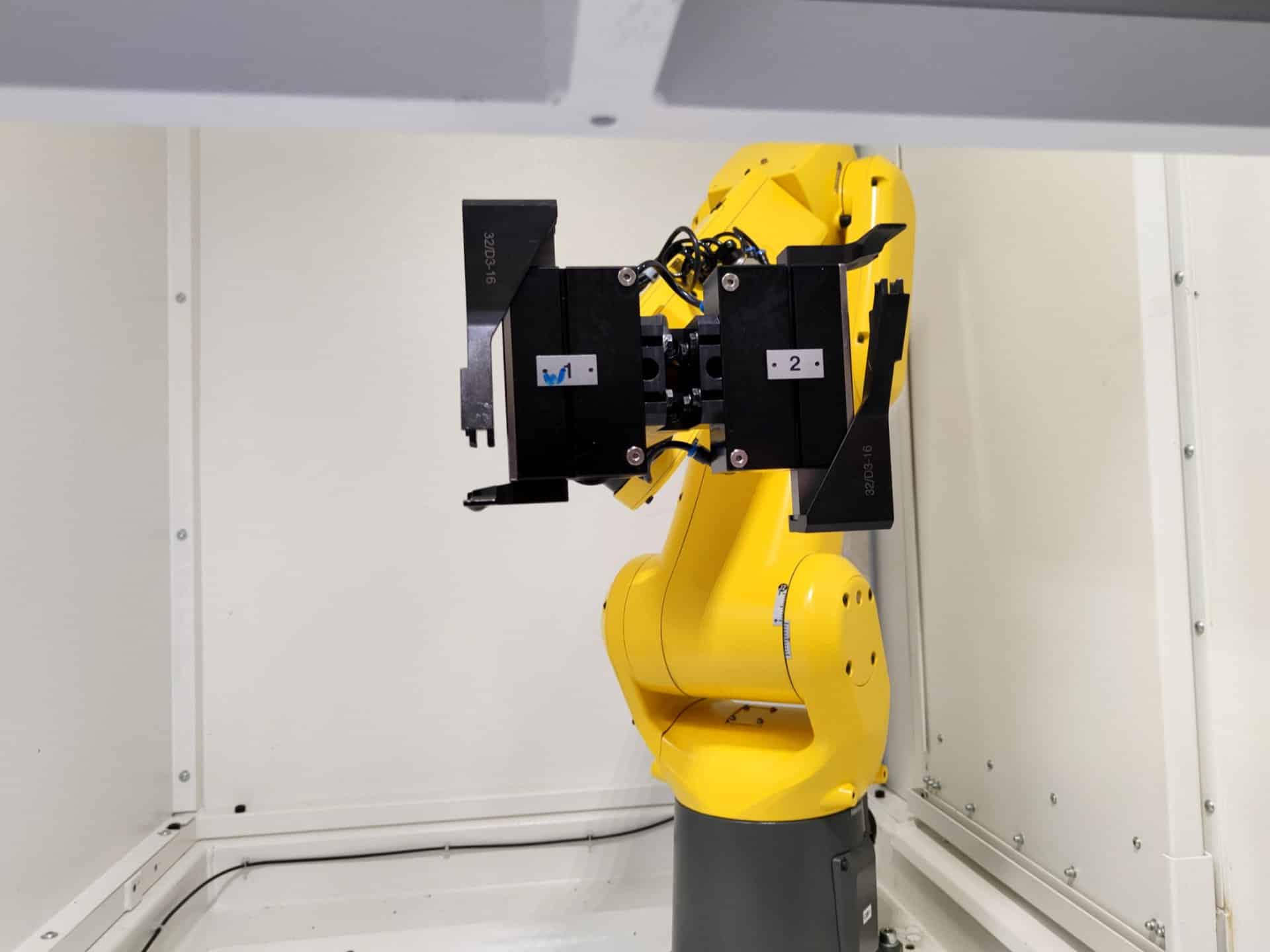

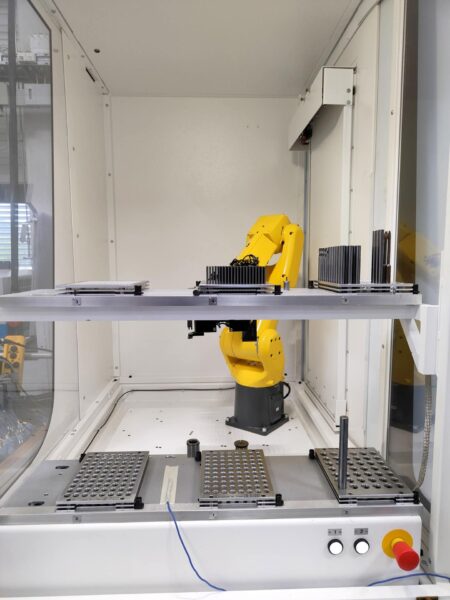

- workpiece loading/unloading robot

- cooling system with aggregate and filter

- tool pallet fi 12 (2 pcs)

- automatic collet chuck system with collets

- tool set for water mist extraction

- fire extinguisher

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe