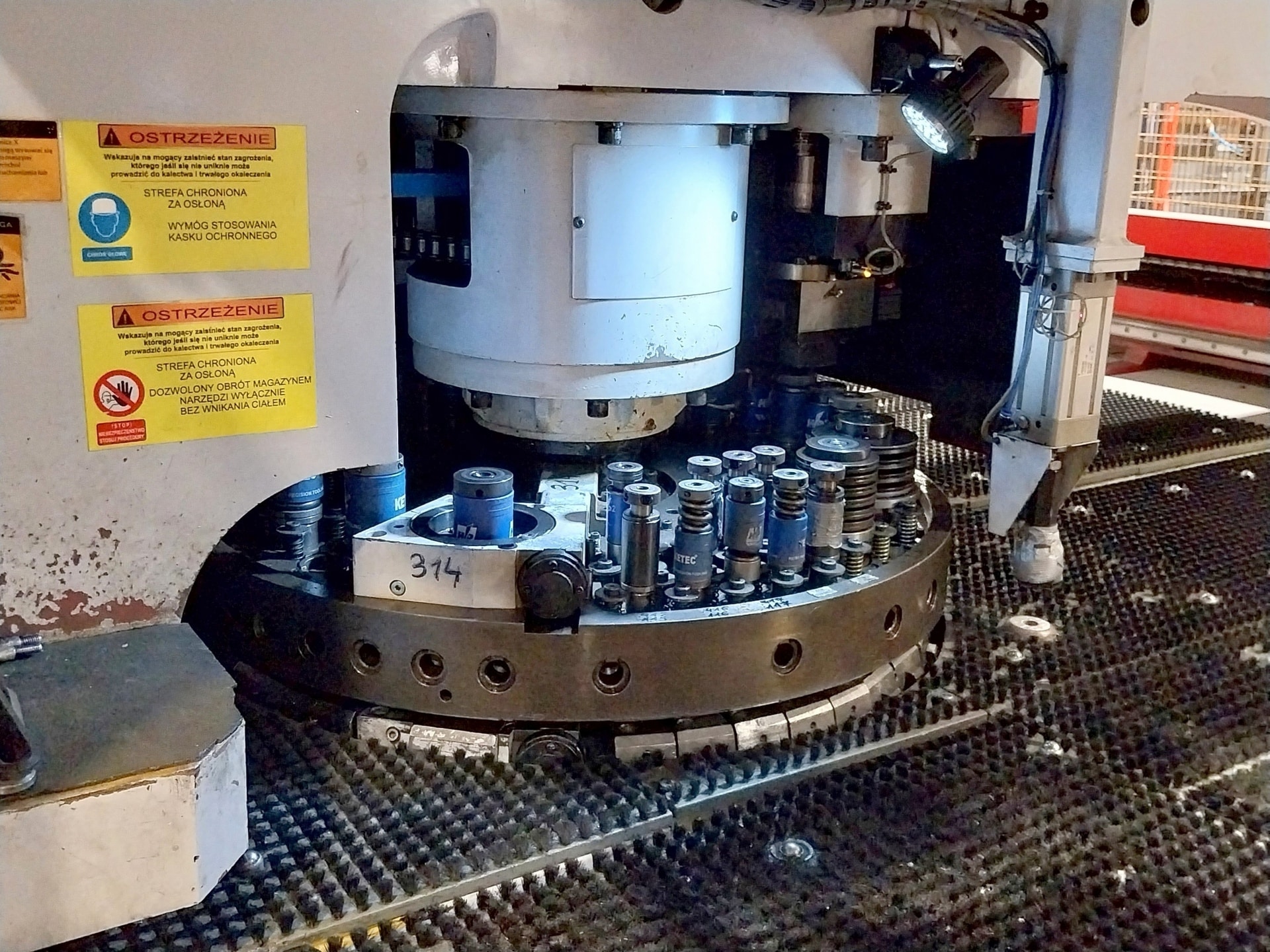

YAWEI NISSHINBO HPI 3048 turret punch press was built in 2011 in China by Jiangsu Yawei Machine Tool Co., Ltd. The machine is designed for precision machining of sheet metal with a maximum thickness of 6.35 mm. The machining process is carried out using a reliable work head, operating with a maximum force of 30 tonnes. The material feed, on the other hand, is carried out on a large brush table, which prevents scratches and nicks on the workpiece surface and significantly reduces noise levels. This is complemented by an intelligent SIEMENS CNC control with many useful functions. The HPI-3048-36LA2 CNC punching machine weighs 18000 kg.

Technical specifications of the YAWEI NISSHINBO HPI 3048 turret punching machine

- CNC control: SIEMENS SINUMERIK 802D

- number of axes: 5 (X,Y,T,C,Z)

- maximum punching force: 30 t

- maximum sheet metal thickness: 6.35 mm

- maximum sheet metal dimensions (L x W): 2500 x 1250 mm

- maximum sheet metal weight: 180 kg

- maximum sheet metal weight (at maximum punching speed): 60 kg

- feed rate in the X/Y axis: 75/70 m/min

- tool stroke length: 40 mm

- maximum tool diameter: 88.9 mm

- number of tool strokes in the X axis: 580/min

- number of tool strokes in the Y axis: 500/min

- turret rotation speed: 30 rpm

- punching accuracy: ± 0.10 mm

- hydraulic system pressure: 7 MPa

- pneumatic system pressure: 0,6 MPa

- compressed air consumption: 0,25 m3/min

- power: 45 kW

- electricity consumption: 28 kVA

- ambient temperature: +10°C/+35°C

- noise level: 83-91 dB(A)

- power supply: 3x 400 V; 50 Hz

- weight of the YAWEI NISSHINBO HPI 3048 machine: 18000 kg

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe