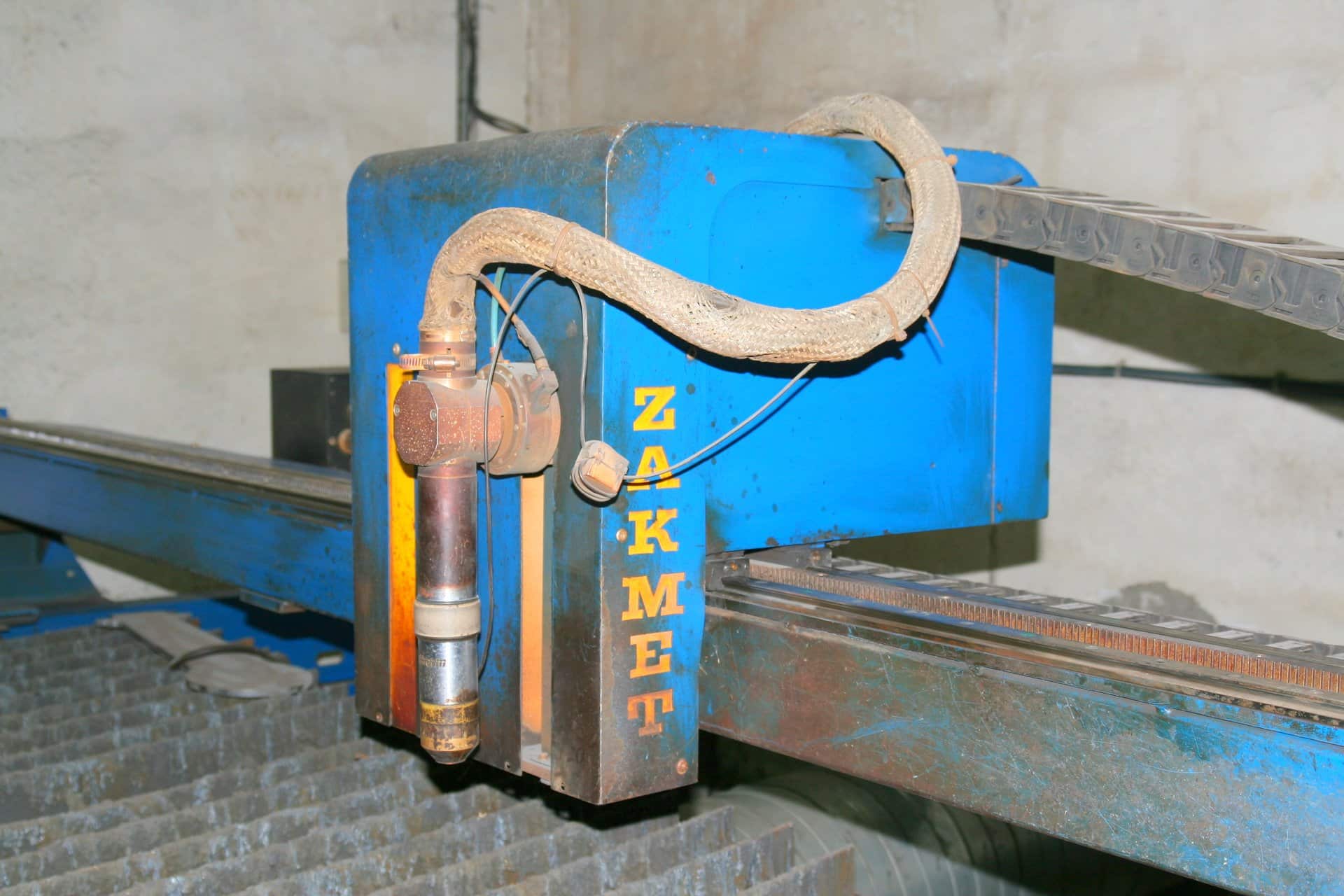

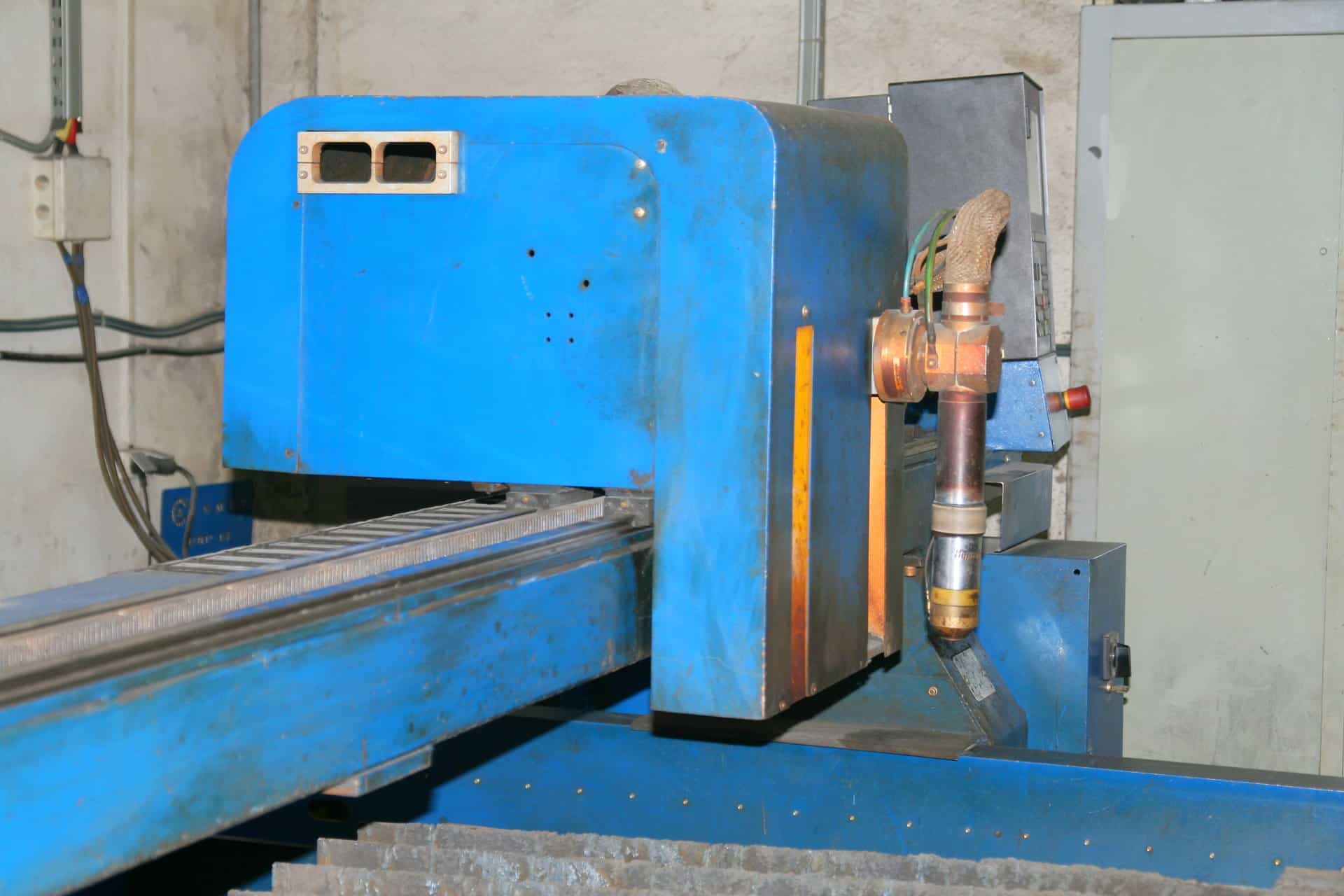

ZAKMET HYPERZAKMET 6000X2500 plasma cutting machine was built in 2008 in Poland. The machine is used to cut pre-programmed shapes in details having a maximum thickness of 38 mm (carbon steel) or 20 mm (aluminium and stainless steel). A powerful HYPERTHERM HyPerformance HPR 130 laser source with a power of 130 A is used for the cutting process, allowing extremely precise and accurate machining to be achieved.

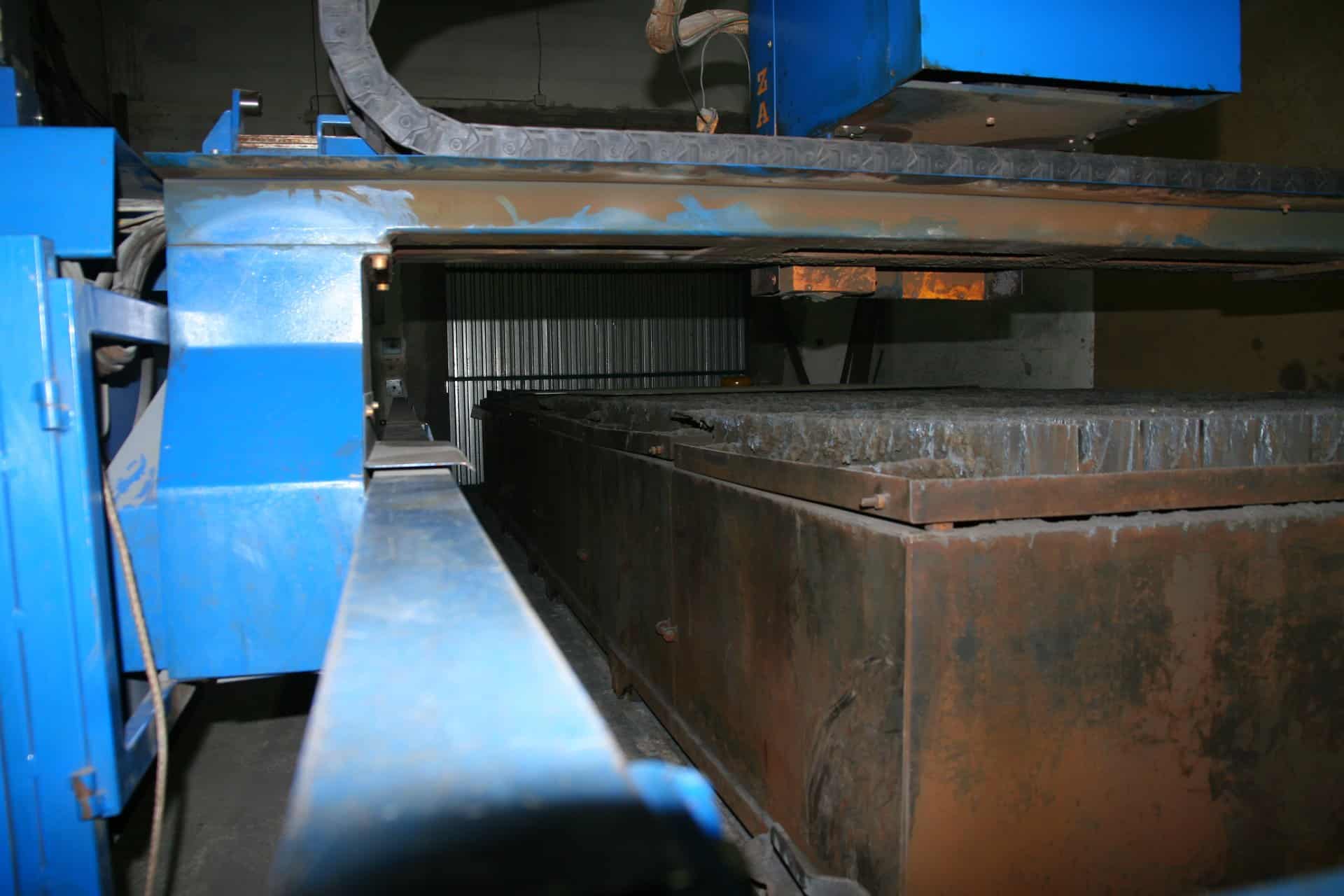

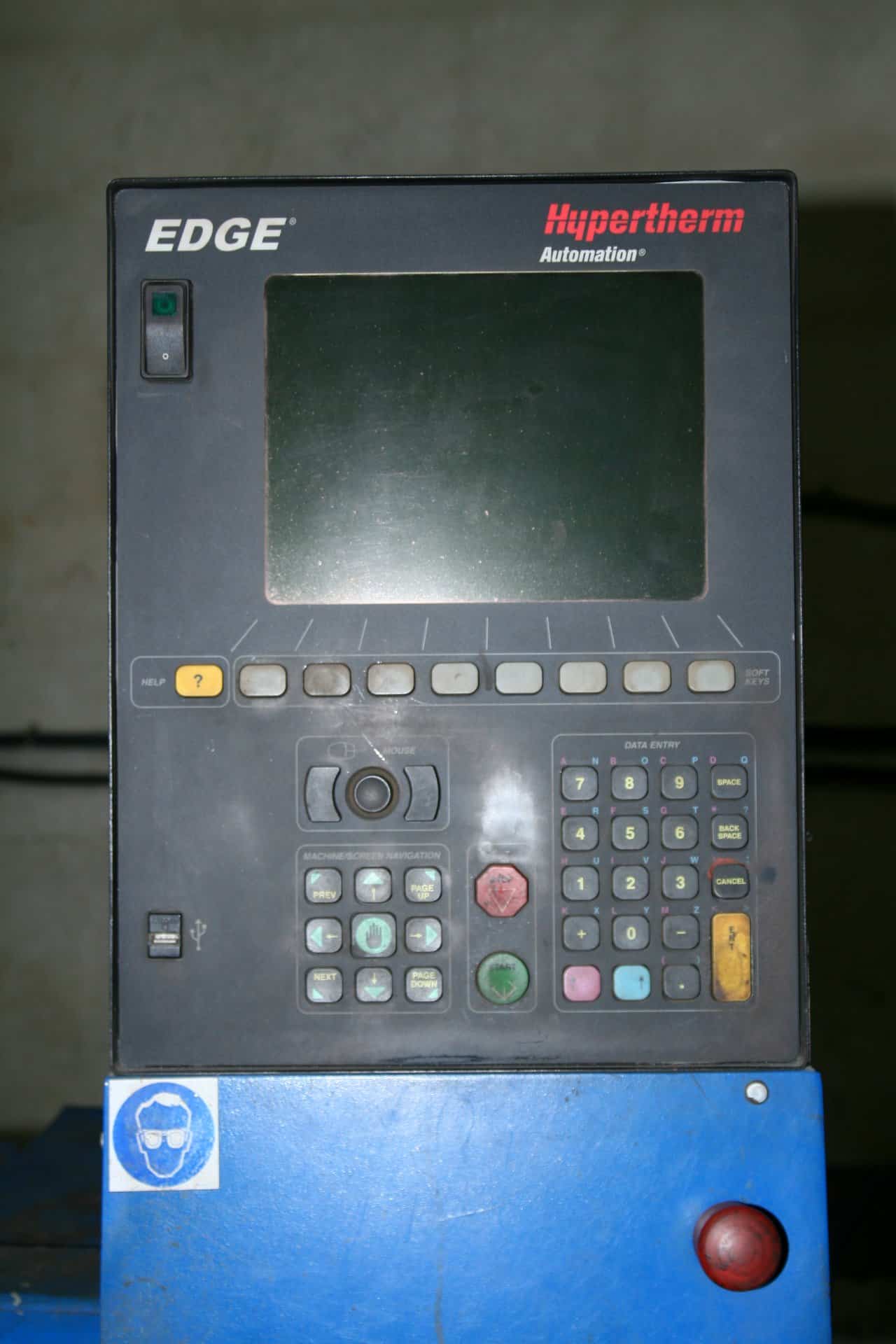

The plasma cutting machine has a solidly built work table with a length of 6000 mm and a width of 2500 mm, which can be extended by means of an additional control panel. The plasma cutting machine is also equipped with FASTCAM CAD/CAM software for simple and effective programming of the cut shapes, and a modern HYPERTHERM EDGE CNC controller, which allows for full control of the machine.

Characteristics of the ZAKMET HYPERZAKMET 6000X2500 plasma cutting machine

- working area (length x width): 6000 x 2500 mm

- maximum workpiece thickness (carbon steel): 38 mm

- maximum workpiece thickness (stainless steel): 20 mm

- maximum workpiece thickness (aluminium): 20 mm

- cutting speed: 250-4950 mm/min

- traverse speed: 50-8000 mm/min

- work table height: 600 mm

- table type: extendable (control via additional panel)

- laser source output current: 130 A

- power supply: 230 V; 50 Hz

Equipment of the plasma cutting machine

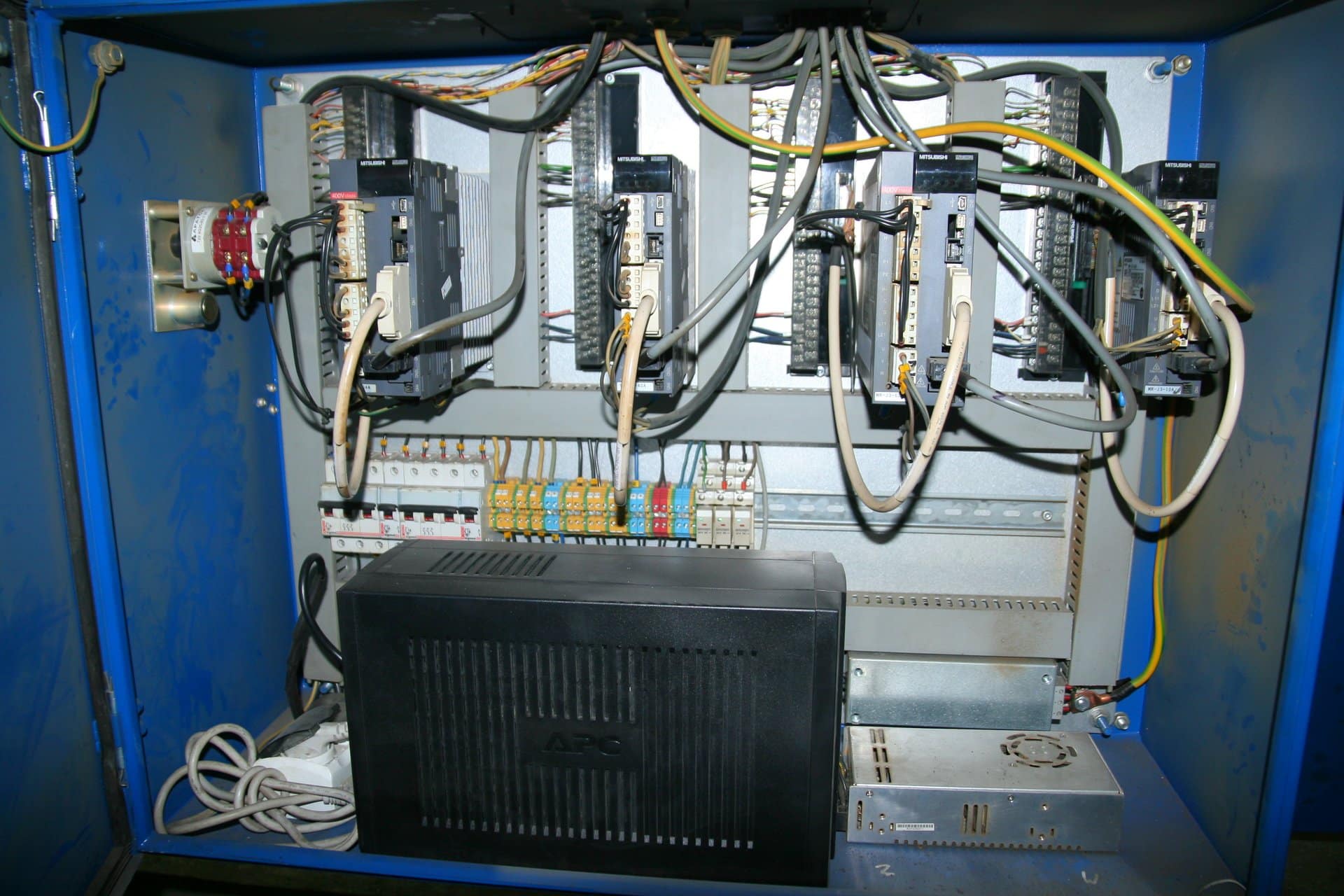

- CNC control: HYPERTHERM EDGE

- laser source: HYPERTHERM HyPerformance HPR 130

- CAD/CAM software: FASTCAM (with dongle)

- refrigeration dryer

- exhaust fan

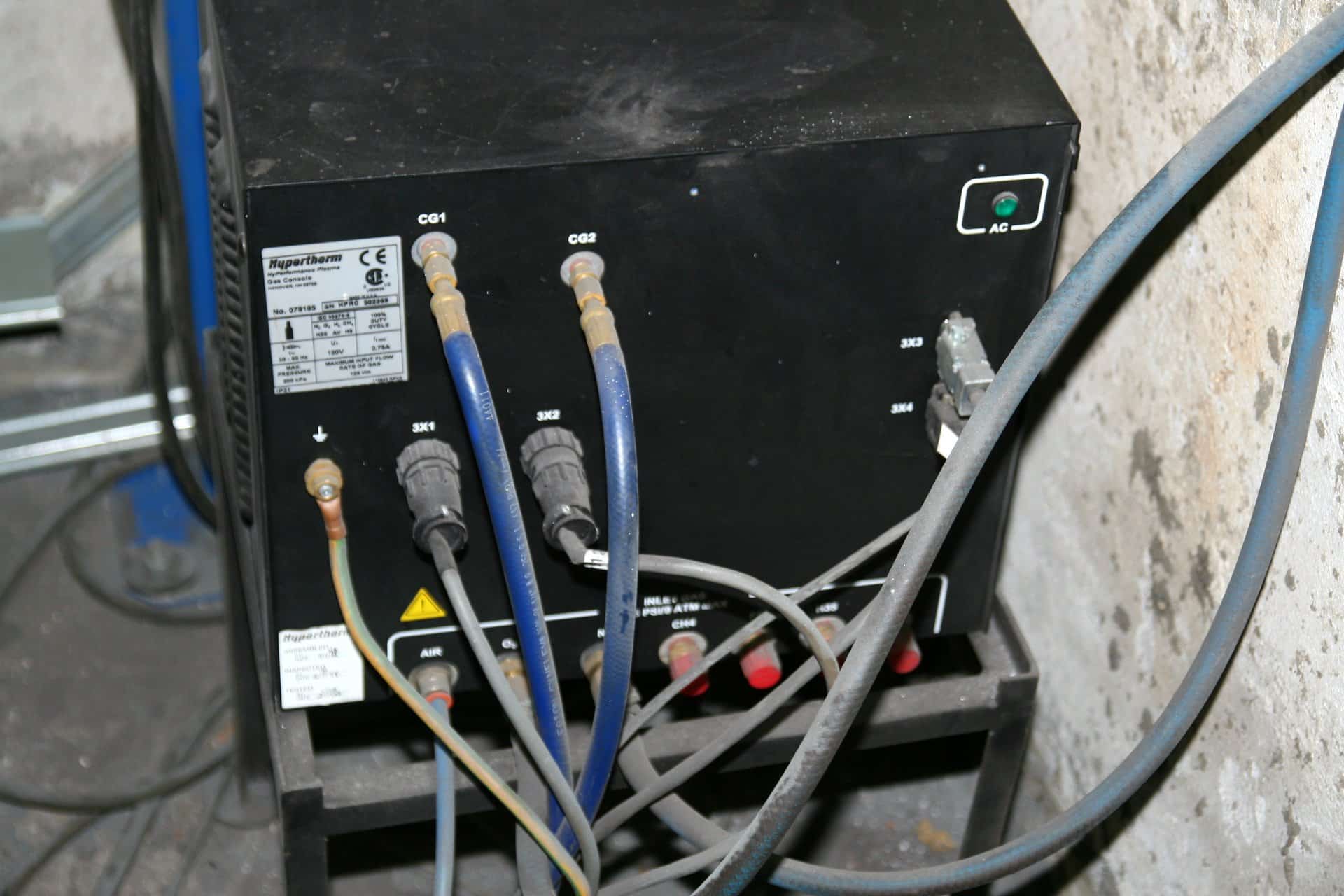

- gas console

- ignition console

- control panel for work table extension

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe