ZDIS GLIWICE YUN 4000-2 oxygen burner was produced by ZDIS Gliwice in 2004. It has a modular table with dimensions of 3×15 m, which can be shortened. The machine is equipped with two oxygen burners, as well as an additional third torch with plasma routing, which enables cutting sheet metal with a maximum width of 4000 mm. The cutter also includes a unit for spraying with water mist, the ASTER program to support the operator’s work and a unit for bevelling the edges at an angle of 0-45 degrees for rectilinear cutting. The cutter is designed for curvilinear oxygen cutting of carbon steel and low-alloy steel sheets.

Technical data of ZDIS GLIWICE YUN 4000-2 cutter

– table dimensions: 15×3 m, it can be shortened because it is modular

– two oxygen burners and additionally a third torch with plasma routing

– maximum cutting width: 4000 mm

– fuel gas: acetylene

– power consumption: approx. 1.5 kVA

– compressed air: min. 0.4 MPa, max. 20 m3 / h

– water: min. 0.1 MPa, max. 0.12 m3 / h

Main groups of the cutter

– roadway

– trolley with longitudinal and transverse drive units

– gas installation

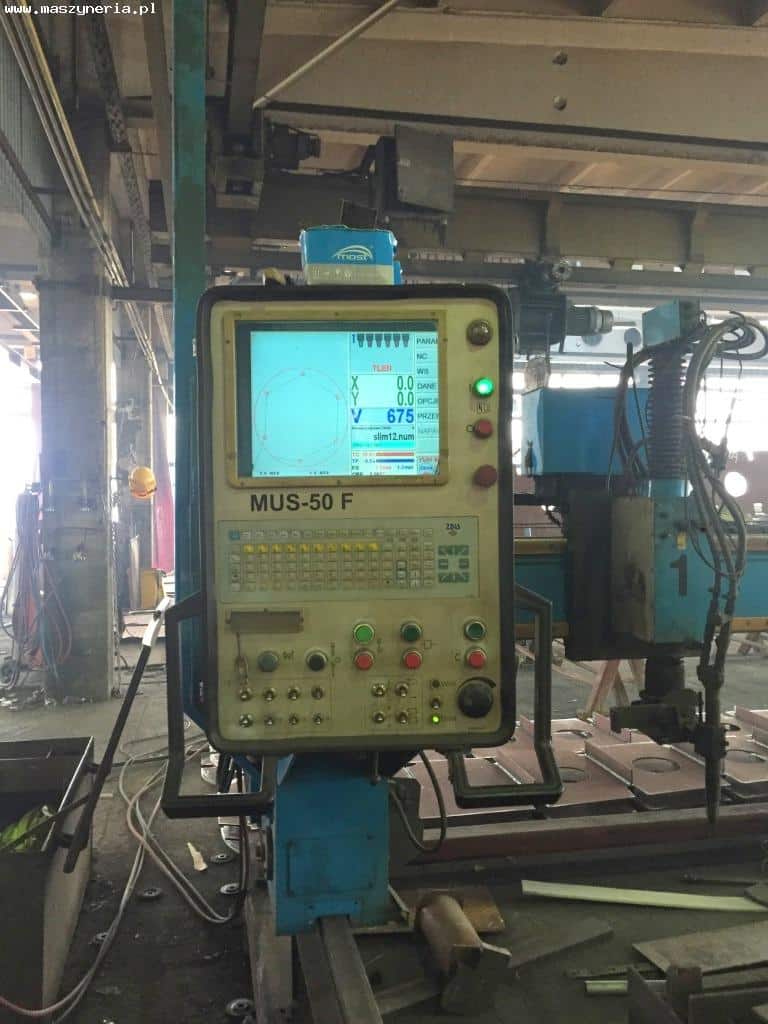

– MUS microcomputer control system

– ZSP control unit

– oxygen supports: 2 pcs.

– power supply installation

– dimensions of a trolley with longitudinal and transverse drive units (W x H x D): 5450 x 1675 x 2500 mm, weight: 1400 kg

– dimensions of the road (length x height x rail spacing): 14000 x 600 x 5000 mm, weight: 1800 kg

– GCE machine torch with burner valves and fuses and a set of nozzles for cutting thickness from 3-150 mm: 2 sets

– Technical Documentation

Accessories:

– water mist spraying unit: 1 pc.

– a unit for bevelling the edges at an angle of 0-45 degrees, for rectilinear cutting: 1 pc.

– ASTER program to support the work of the technologist in developing cutting programs: 1 pc.

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano