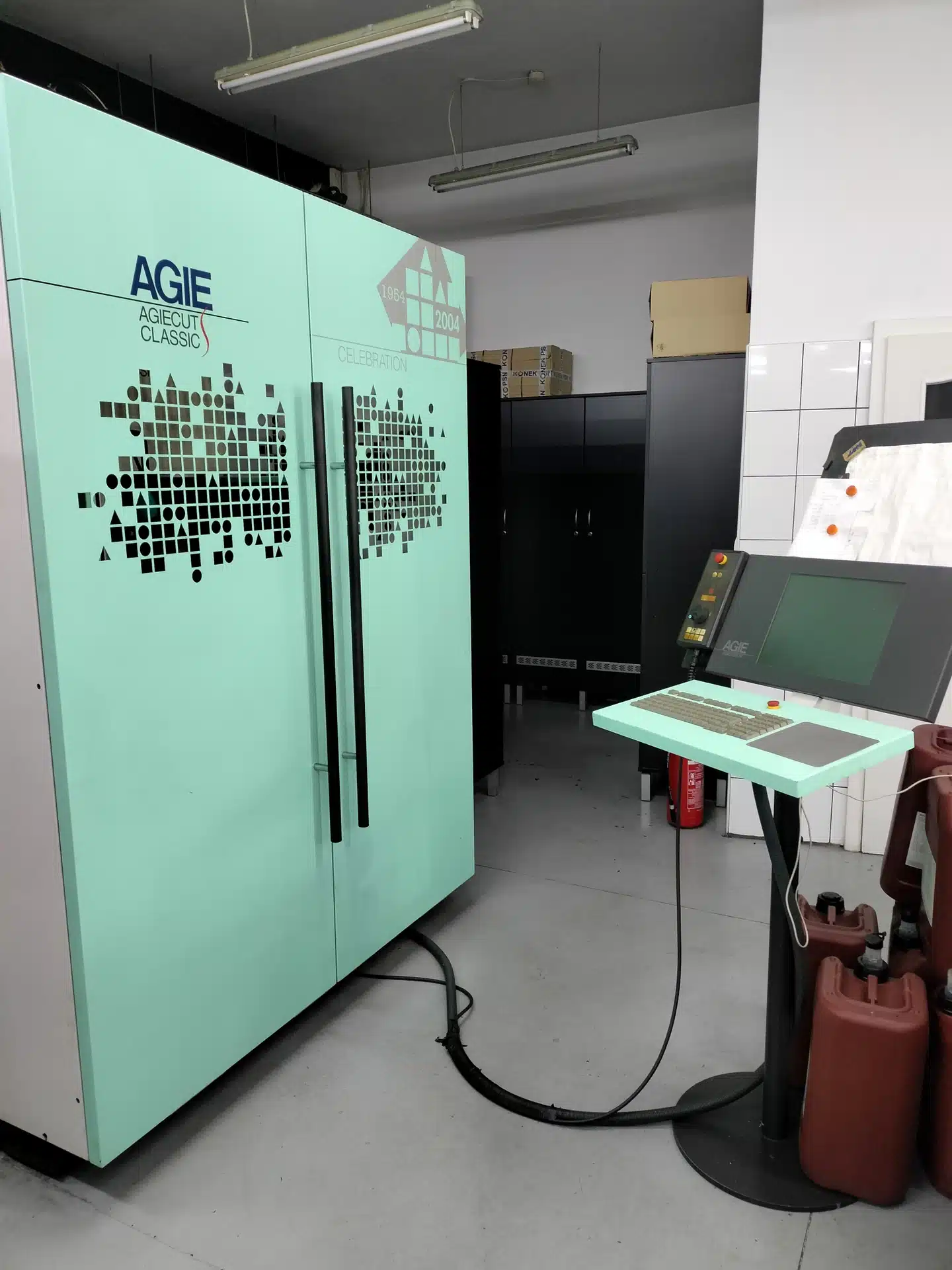

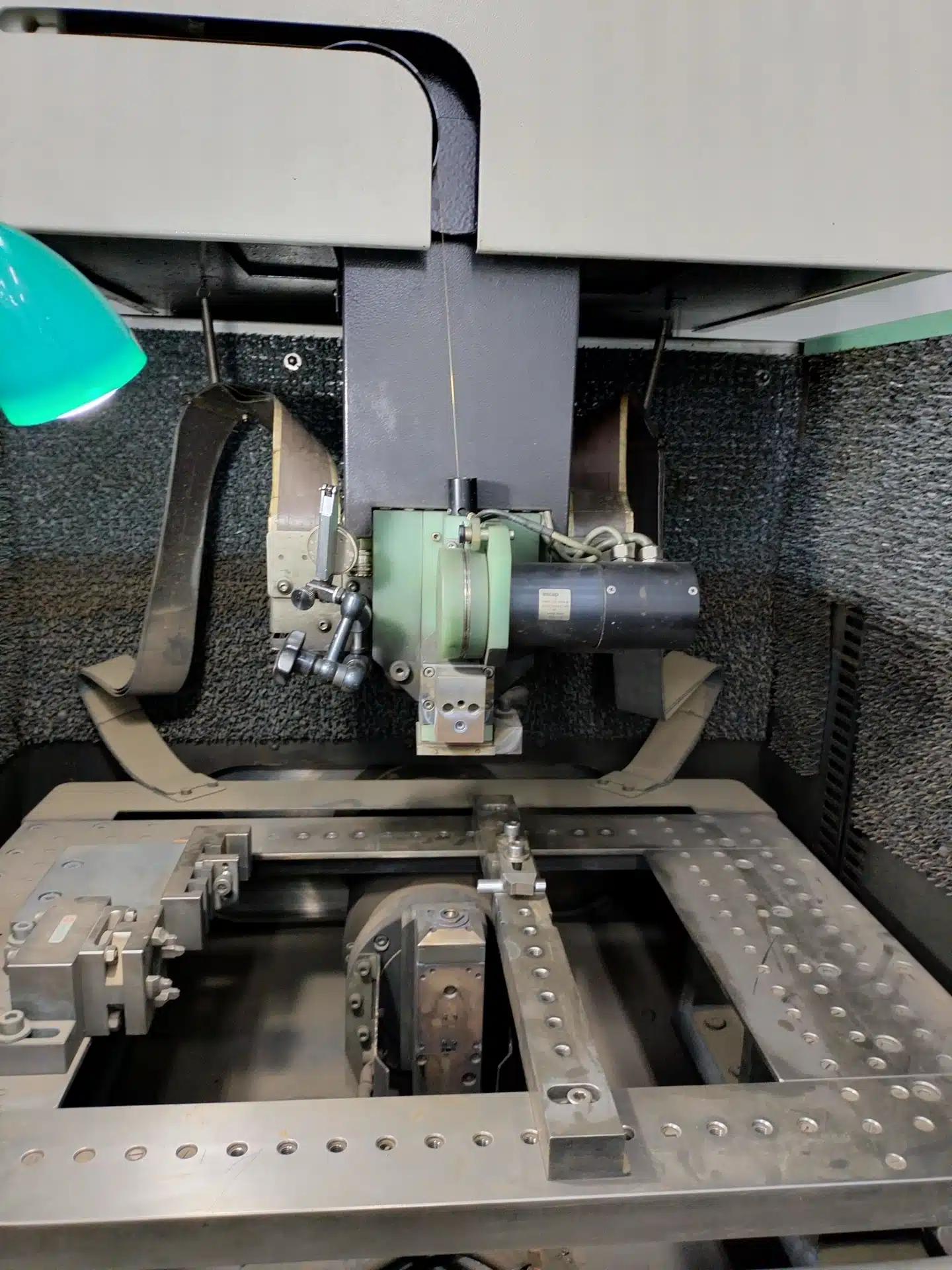

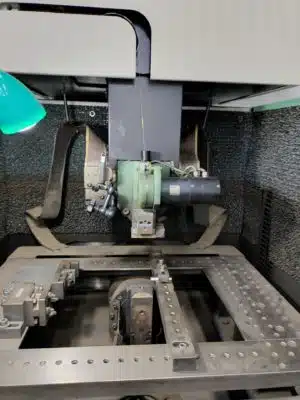

AGIE AGIECUT CLASSIC 2S wire EDM machine built in 2004 in Switzerland is used for the production of, among others, precision dies, tools and punches. Workpieces with a maximum weight of 450 kg are machined using electrical erosion, which can achieve complex shapes in even the hardest materials. This process is performed in a dielectric-filled work tank using a wire with a maximum diameter of 0.33 mm, which is threaded through a special AGIEJET system. The workpieces machined in this way do not require any other secondary processes such as polishing to be undertaken.

The AGIECUT CLASSIC V2 wire EDM machine also features an intuitive CNC control with many useful functions. It is possible to purchase the dedicated cooler shown in the photos at an additional cost – price negotiable. The AGIE EDM machine weighs 2580 kg.

Technical specifications of the AGIE AGIECUT CLASSIC 2S EDM machine

- CNC controller: AGIE AGIEVISION

- feed in the X/Y/Z axis: 350/250/256 mm

- feed in U/V axis: ± 70/ ± 70 mm

- maximum workpiece dimensions (L x W x H): 750 x 550 x 250 mm

- maximum workpiece height (with bath): 150 mm

- maximum workpiece weight: 450 kg

- maximum workpiece weight (with bath): 200 kg

- maximum taper angle: ± 30°/100 mm

- V guide : cylindrical to 2°

- toroide guide: 2-30°

- semi-automatic wire threading system AGIEJET

- maximum wire diameter: 0.33 mm

- minimum wire diameter: 0.15 mm

- wire speed: 60-300 mm/s

- wire tension: 0-25 N

- threadable height: up to 250 mm

- threading speed: 15 s

- maximum wire spool weight: 25 kg

- maximum manual positioning speed in X,Y axis: 0.9 m/min

- maximum programmable positioning speed in X,Y axis: 0.9 m/min

- maximum manual and programmable positioning speed in U,V,Z axis: 0.6 m/min

- 15″ TFT colour operating panel

- work tank volume: 750 l

- dielectric level: 0-190 mm

- distance from floor to workpiece clamping level: 1075 mm

- flushing pressure: programmable from 0.2 to 18 bar

- dimensions (L x W x H): 1670 x 2040 x 2305 mm

- weight of machine: 2580 kg