PowerMill 3117 CNC milling machine was built in 2019 in Poland by Mizera Automation. The machine’s welded steel profile structure, together with the large vacuum table, guarantees excellent stability and rigidity while machining workpieces made of steel, aluminium, as well as wood and plastics. The X/Y/Z axes are equipped with servo drives with RTE (Real Time Ethernet) protocol communication capability, achieving high repeatability of movements.

Workpieces are machined with the highest precision and speed, thanks to the use of HSM (High Speed Machining) technology. The extremely powerful spindle of the milling machine operates at a maximum speed of 24000 rpm. The milling machine has extensive equipment, comprising, amongst others, a stationary tool magazine with automatic tool changer, light curtains and a CNC controller with CAD/CAM software.

Technical specifications of the PowerMill 3117 CNC milling machine

- workspace in the X/Y/Z axis: 1900x3100x300 mm

- maximum workpiece weight: 2000 kg

- maximum spindle speed: 24000 rpm

- spindle power: 9 kW

- maximum feed rate idle motion: 18 m/min

- Z axis positioning accuracy: < 0.05 mm

- working accuracy: ± 0.05 mm

- head positioning accuracy: ± 0.03 mm

- maximum resolution of head positioning: 0.01 mm

- spindle cooling: air

- tool cooling: oil mist

- supported format: DXF

- power of X/Y/Z axis servo drives: 2×750/750/400 W

- POWER MILL 3117 machine power supply: 400 V; 50 Hz

Equipment of the milling machine

- CNC controller

- CAD/CAM software

- stationary tool magazine with a capacity of 12 pcs.

- automatic tool changer

- X/Y/Z axis servo drives with communication over RTE protocol (Real Time Ethernet)

- light curtains

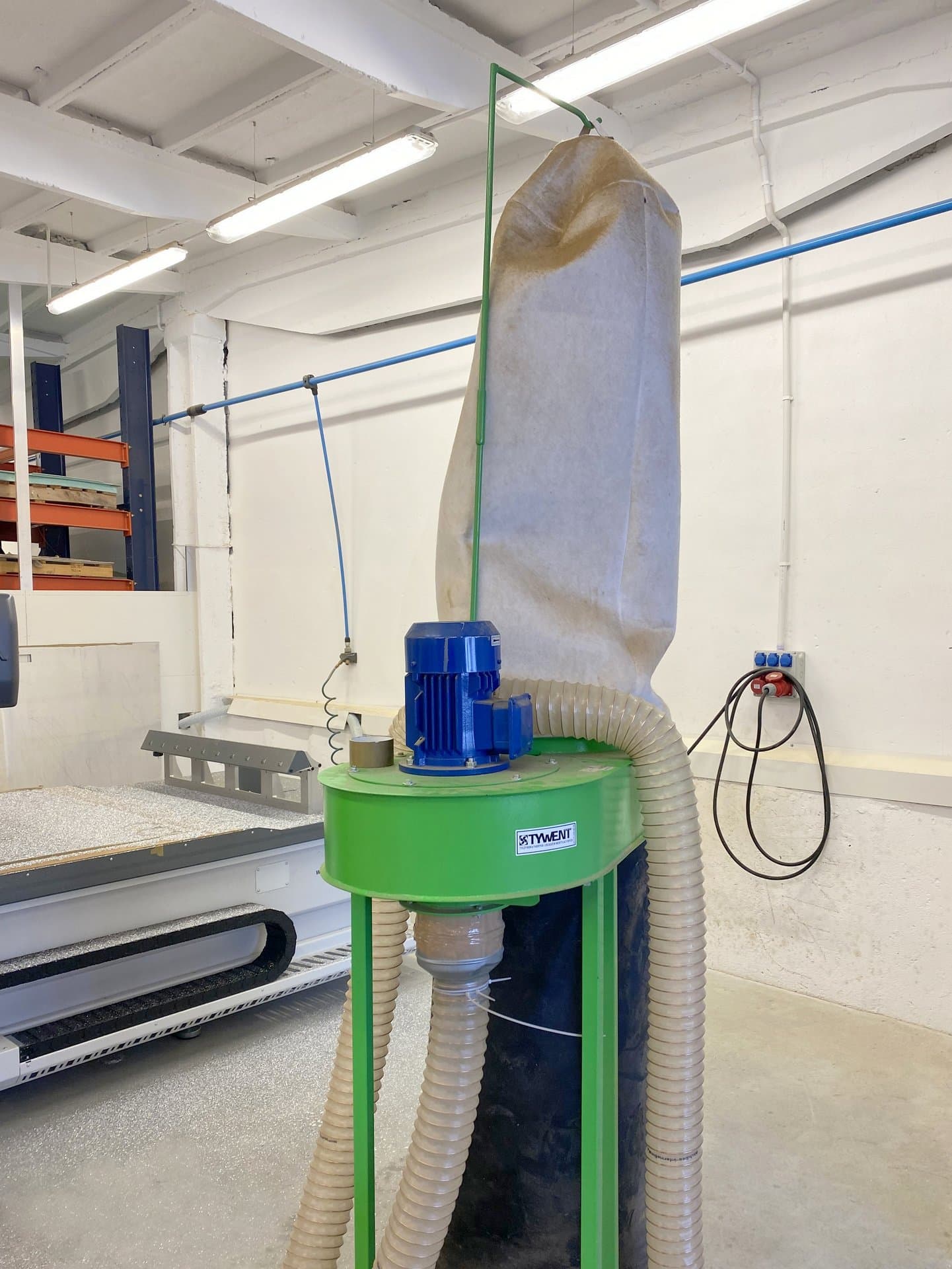

- chip extraction system

- end measuring sensors for each axis

- system with electronic door angle correction

- backlash-free 20 mm prism guides

- pneumatic pins (4 pcs.)

The machine underwent modernisation in March 2022, during which a general overhaul of the spindle was carried out at a cost of approximately PLN 17000 net.

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe