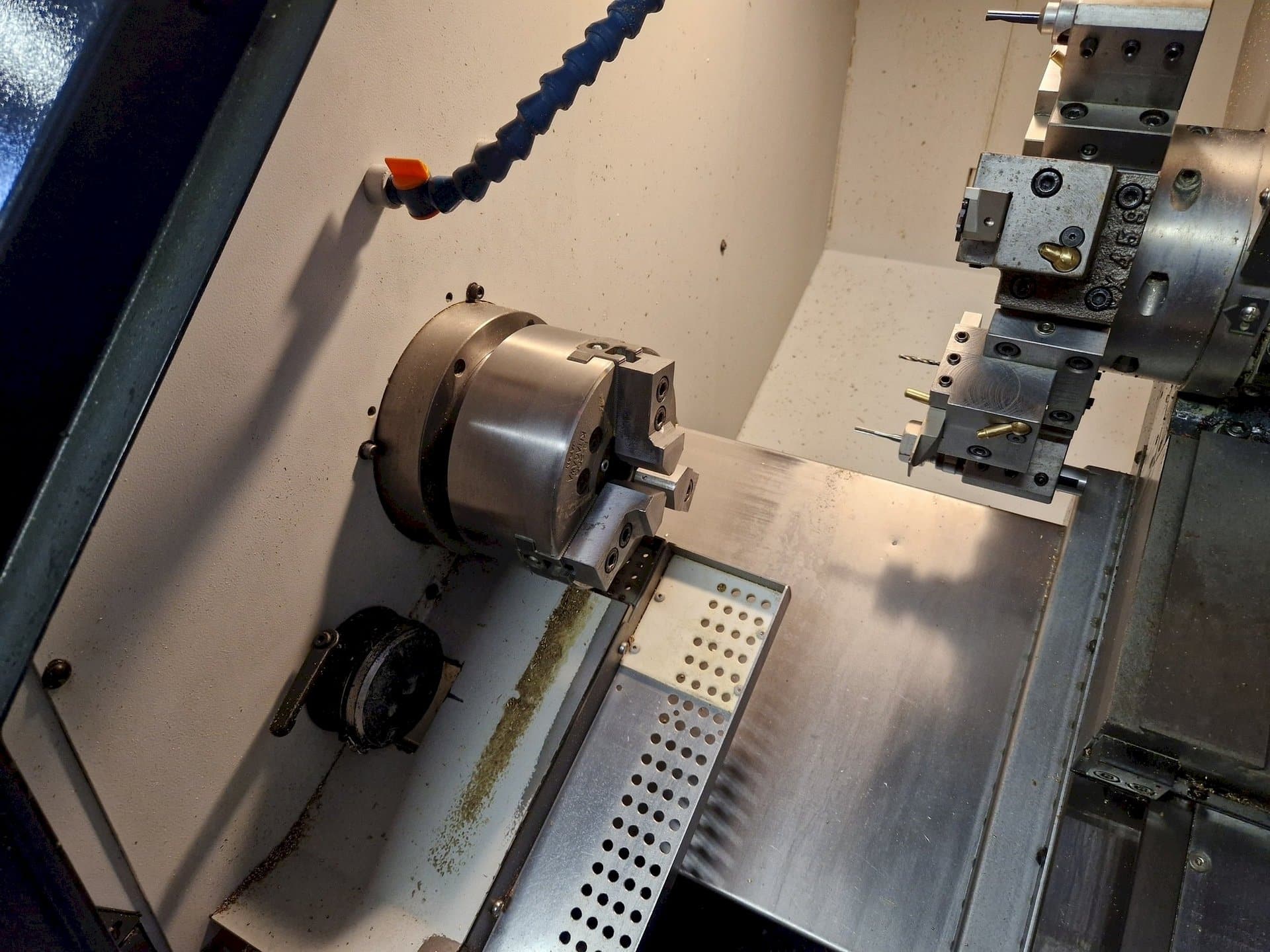

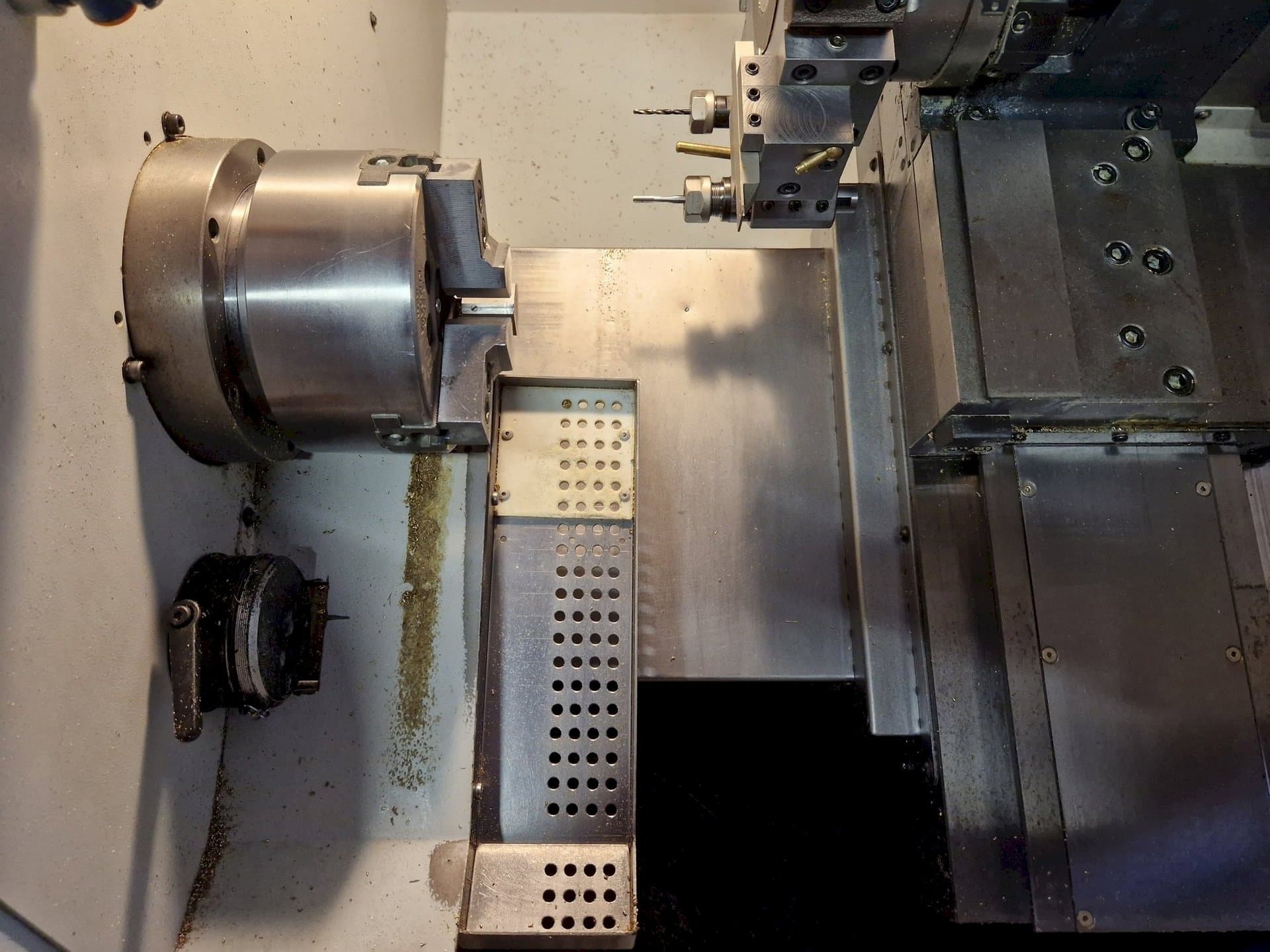

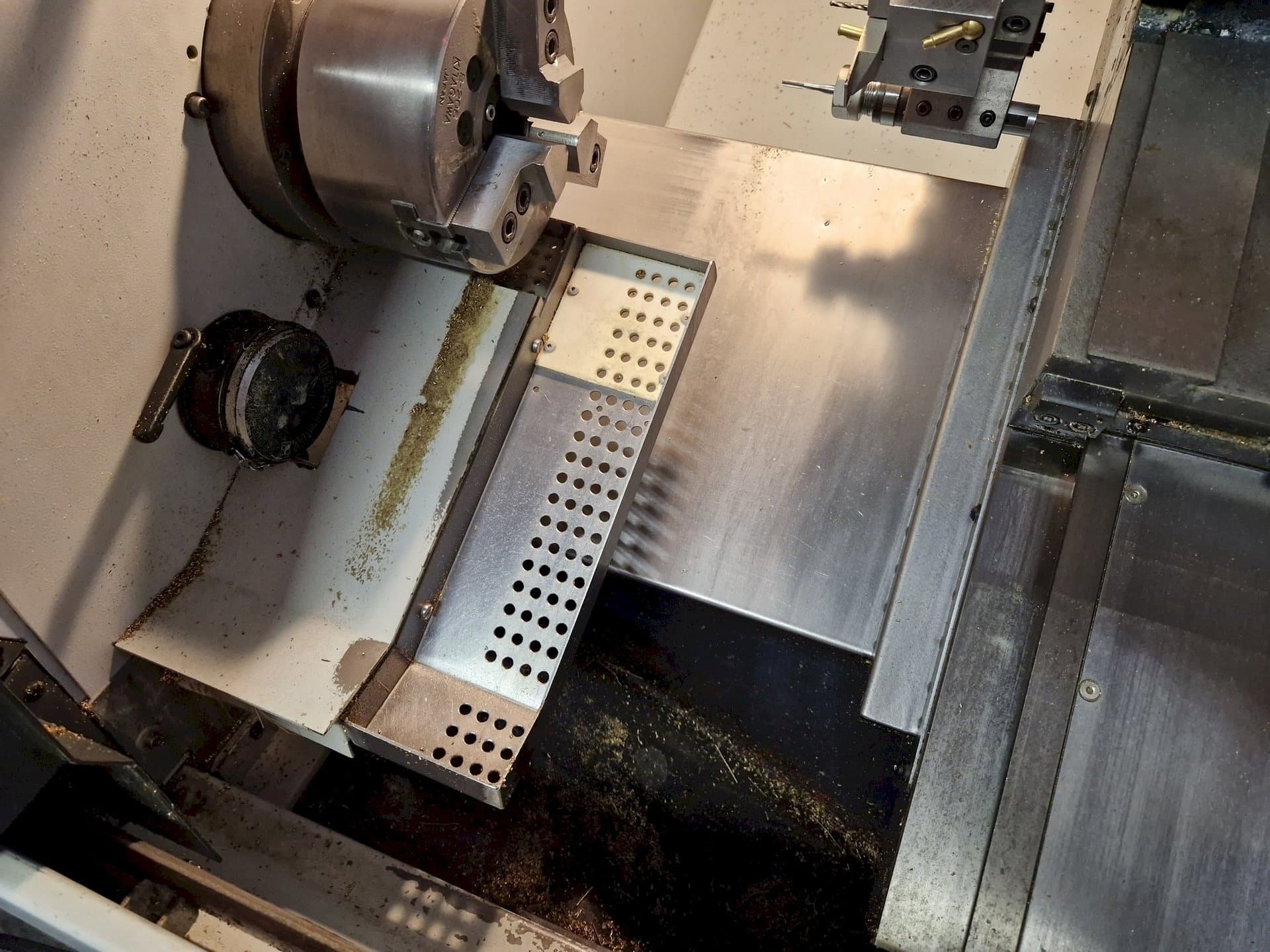

GOODWAY TS-150M CNC lathe was manufactured in 2008 in Taiwan. The machine’s small dimensions and compact, stable design allow it to achieve high precision turning of workpieces made of aluminium, iron, cast iron, copper and stainless steel, even during the most intensive work. Workpieces with a maximum diameter of 220 mm and a length of 305 mm are machined in manual or automatic mode by using the installed FANUC Series 0i-TC CNC control.

The CNC lathe has a fully illuminated workspace, inside of which there is, for example, a 152 mm diameter chuck with automatic hydraulic clamp, hardened induction slide guides and an extremely precise spindle rotating at a maximum speed of 6000 rpm. Equipment of the machine includes among others tool holders and a YOEN MB-CE transformer. The GOODWAY TS 150M turning centre weighs 1800 kg.

Technical specifications of the GOODWAY TS-150M lathe

- maximum turning diameter: 220 mm

- maximum turning length: 305 mm

- feeds in X/Z axes: 305/320 mm

- rapid traverse in X,Z axis: 24 m/min

- positioning accuracy in X,Z axis: ± 0,005 mm

- repeatability accuracy in X,Z axis: ± 0,003 mm

- maximum bar diameter: Ø 42 mm

- chuck diameter: 152 mm

- maximum spindle speed: 6000 rpm

- minimum spindle speed: 60 rpm

- maximum spindle passage: 55 mm

- spindle motor: FANUC β3/10,000i

- spindle power (constant operation/ 30 min): 4/5.5 kW

- passage over support guard: 330 mm

- passage over cross slide: 60 mm

- maximum passage over extension sleeve: 45 mm

- internal diameter of front bearing: 80 mm

- height of tusk above floor: 1040 mm

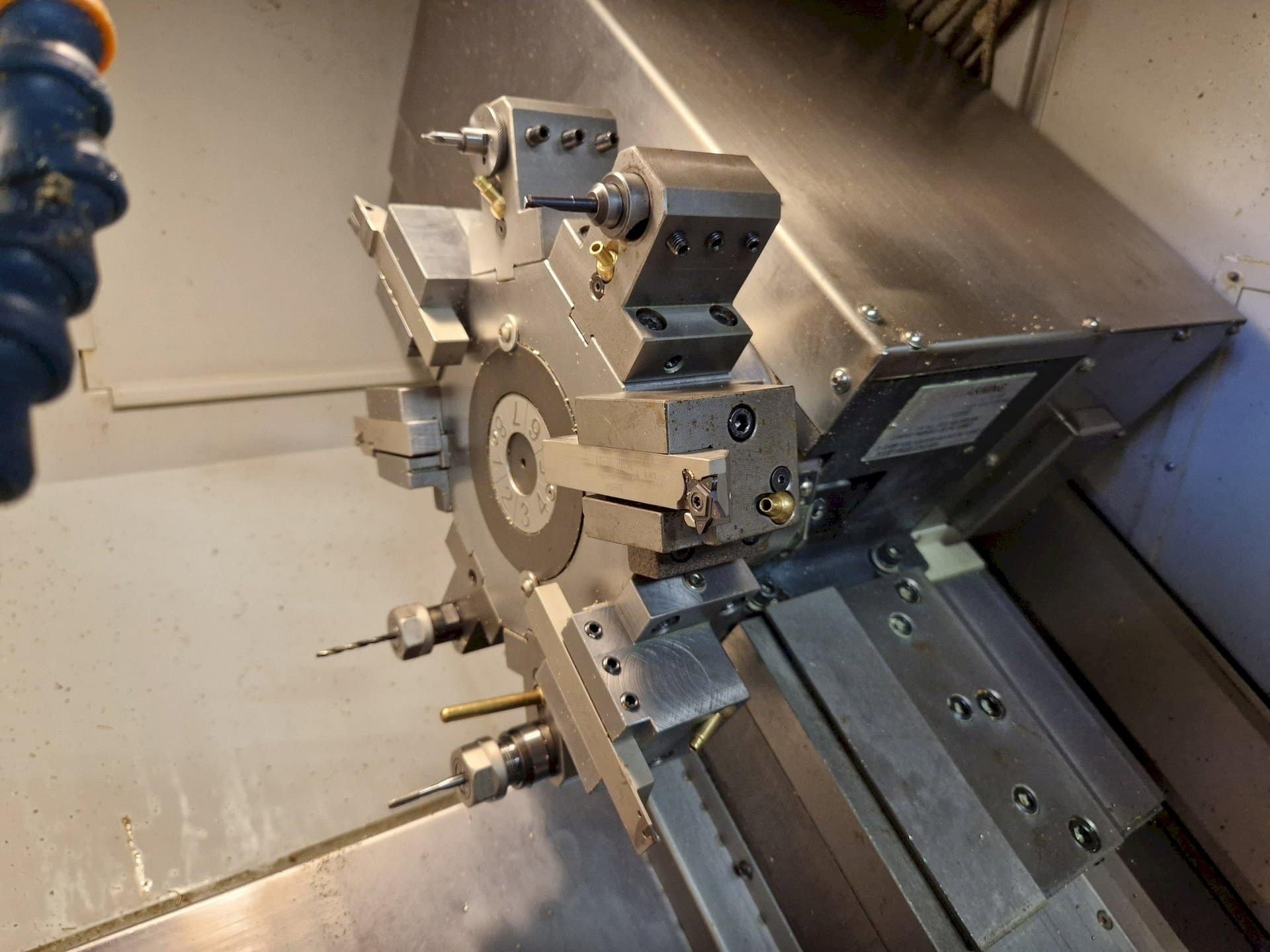

- number of positions in tool head: 8

- number of driven tool positions: 8

- tool dimensions (square): 20 x 20 mm

- tool dimensions (round): ø 25 mm

- tool head positioning accuracy: 0,00069°

- tool head repeatability accuracy: 0,00027°

- head indexing drive: FANUC AC servo motor

- head indexing time (setting): 0,2 s

- head indexing time (180° rotation): 0,5 s

- CS-axis drive type: spindle motor

- minimum CS-axis indexing accuracy: ± 0,001°

- CS-axis dynamic accuracy: ± 0.02°

- maximum workpiece length (workpiece receiver): 180 mm

- maximum workpiece diameter (workpiece receiver): Ø 60 mm

- maximum workpiece weight (workpiece receiver): 4 kg

- thrust force in X,Z axes: 190 kgf

- ball screw diameter in X,Z axis: 28 mm

- ball screw stroke in X,Z axis: 8 mm

- hydraulic system tank capacity: 40 l

- cooling tank capacity: 80 l

- cooling system pump motor power: 0,2 kW

- hydraulic pump motor power: 0,75 kW

- noise level: 80 dB(A)

- power supply: 3x 220 V; 50/60 Hz

- dimensions (L x W x H): 1705 x 1350 x 1777 mm

- weight of the TS-150M machine: 1800 kg

Equipment of the lathe

- CNC control: FANUC Series 0i-TC

- C axis on spindle

- transformer: YOEN MB-CE

- 3-jaw chuck KITAGAWA with a diameter of 152 mm

- measuring probe

- X,Z axis AC servo motors 0.9 kW

- turret head with drive for 8 tools

- lubrication system pump motor: SHOWA MV30103B 220 V

- spindle tip: A2-5

- hardened induction slide guides

- workpiece receiver

- belt chip receiver

- central lubrication

- set of soft jaws for chuck

- bar clamp

- knives

- toolholder 0° (3 pcs.)

- toolholder 90° (3 pcs.)

- levelling insert set

- cutters

- toolbox

- spindle orientation and rigid hole tapping

- cooling system GRUNDFOS 3 bar

- ventilated electric cabin

- full cabin with impact-resistant glass and locking doors

- workspace illumination

- safety interlock for clamping failure

- illuminated alarm system

- pressure switch for power failure

- full technical documentation

- CE marking and certificate

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe