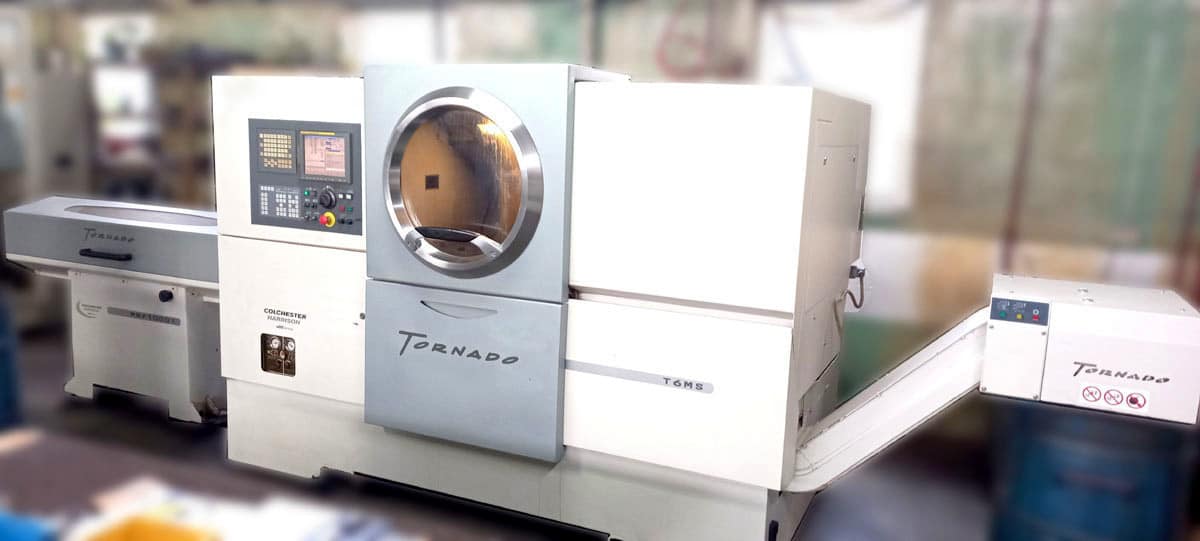

COLCHESTER HARRISON TORNADO T6MS CNC turning centre was built in 2007 in the United Kingdom. A highly reliable lathe used for a wide range of workpiece machining with a maximum diameter of 220 mm, uses driven tools and extensive equipment to achieve excellent accuracy of surface finish in such operations as drilling, boring and threading.

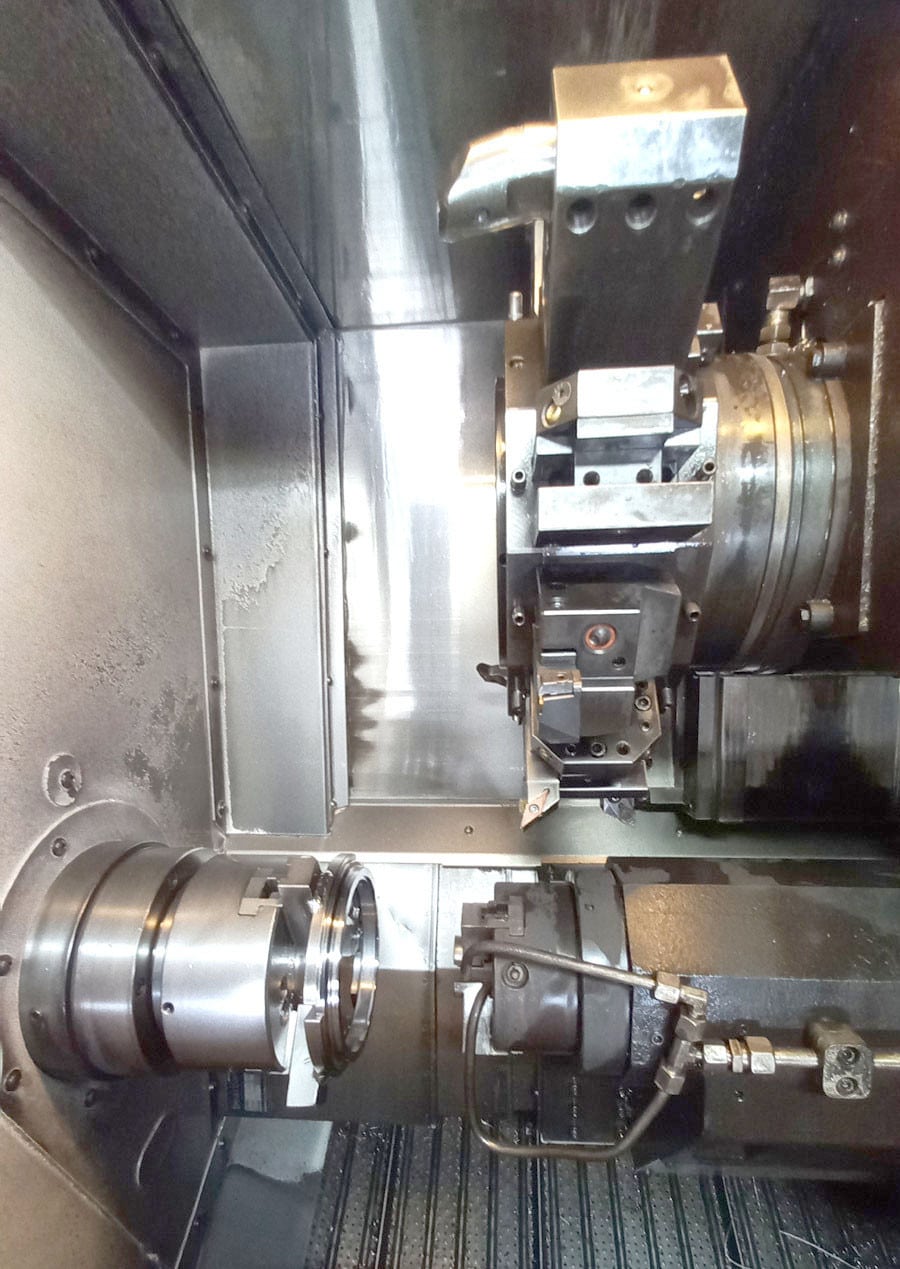

A solid cast iron bed set on a structure filled with specially developed polymer concrete achieves accuracy as well as thermal and dynamic stability during turning of up to 300% greater than cast iron. Turning takes place in the fully illuminated machine workspace equipped with a powerful 15 kW main spindle and a sub spindle that rotates at a maximum speed of 6000 rpm. This solution allows for automatic transfer of the workpiece between the two spindles in order to continue turning, milling and drilling on the other side of the workpiece.

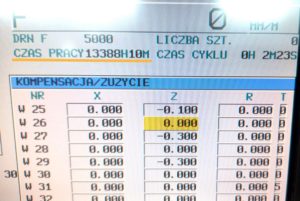

The TORNADO T6MS CNC lathe has a wide range of equipment, including e.g. a bar feeder to increase productivity during longer production runs, a state-of-the-art FANUC Series 18i-TB CNC control for convenient input of machining parameters and machine control, a 3-jaw hydraulic chuck and a 12-position tool head. The automatic lathe weighs approximately 4500 kg

Technical specifications of the COLCHESTER HARRISON TORNADO T6MS lathe

- maximum turning diameter: 220 mm

- swing over bed: 440 mm

- feed rates in the X/Z/A axis: 200/450/450 mm

- rapid traverse in the X/Z/A axes: 25/30/30 m/min

- maximum spindle speed: 6000 rpm

- spindle taper: A2-5

- spindle chuck size: 170 mm

- spindle bore: 64 mm

- distance between spindle axis and floor: 950 mm

- internal drawtube diameter: 54 mm

- internal spindle bearing diameter: 95 mm

- spindle motor power: 15 kW

- maximum bar length: 1000 mm

- maximum bar diameter: 54 mm

- width across cross guideways (A axis): 240 mm

- minimum jaw-to-jaw travel (A axis): 20 mm

- maximum jaw-to-jaw travel (A axis): 470 mm

- maximum sub spindle speed: 6000 rpm

- sub spindle taper: DIN 6353

- sub spindle bore: 55 mm

- sub spindle chuck size: ø 130 mm

- sub spindle collet size: 33 mm

- sub spindle drawtube diameter: 40 mm

- sub spindle drawtube length: 370 mm

- sub spindle motor power: 5.5 kW

- sub pture spindle torque: 45 Nm

- number of tool stations in the tool head: 12

- number of driven tool stations: 12

- tool head speed: 5000 rpm

- toolholder: VDI 30

- rotary tool holder: DIN 5482 (16X0.8)

- rotary tool shank size: 20×20 mm

- maximum boring bar diameter: 32 mm

- direction of tool head rotation: bi-directional

- tool head power: 3.75 kW

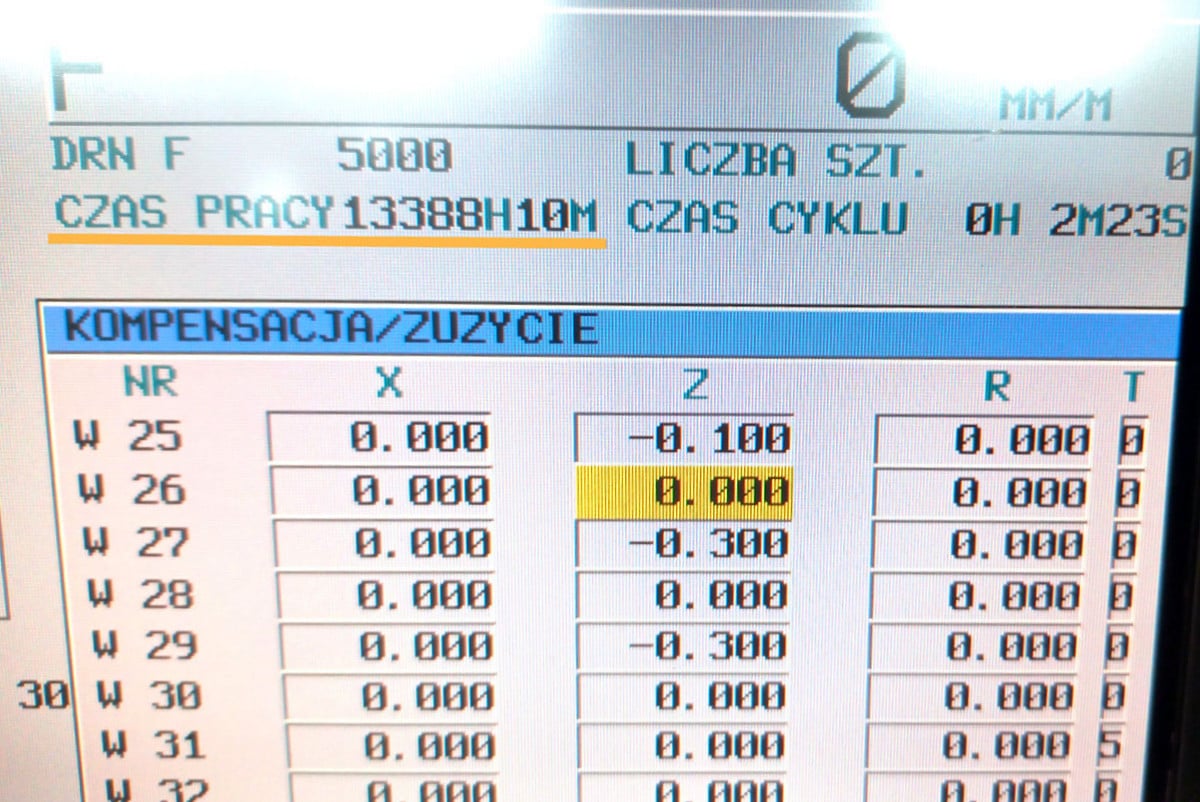

- operating hours: 13388 h

- ball screw diameter in X,Z,A axis: 32 mm

- ball screw pitch in X/Z/A axis: 8/8/10 mm

- thrust in X/Z axis: 3.75/4.445 kN

- C-axis resolution: 0,001°

- B-axis resolution: 0,001°

- carriage inclination: 60°

- coolant tank capacity: 100 l

- coolant pump capacity (pressure 2.5 bar): 25 l/min

- power requirement: 28 kVA

- space requirement: 3,9 m2

- weight of machine TORNADO T6MS: approx. 4500 kg

Equipment of the automatic lathe

- CNC control: FANUC Series 18i-TB

- sub spindle

- bar feeder

- swarf conveyor

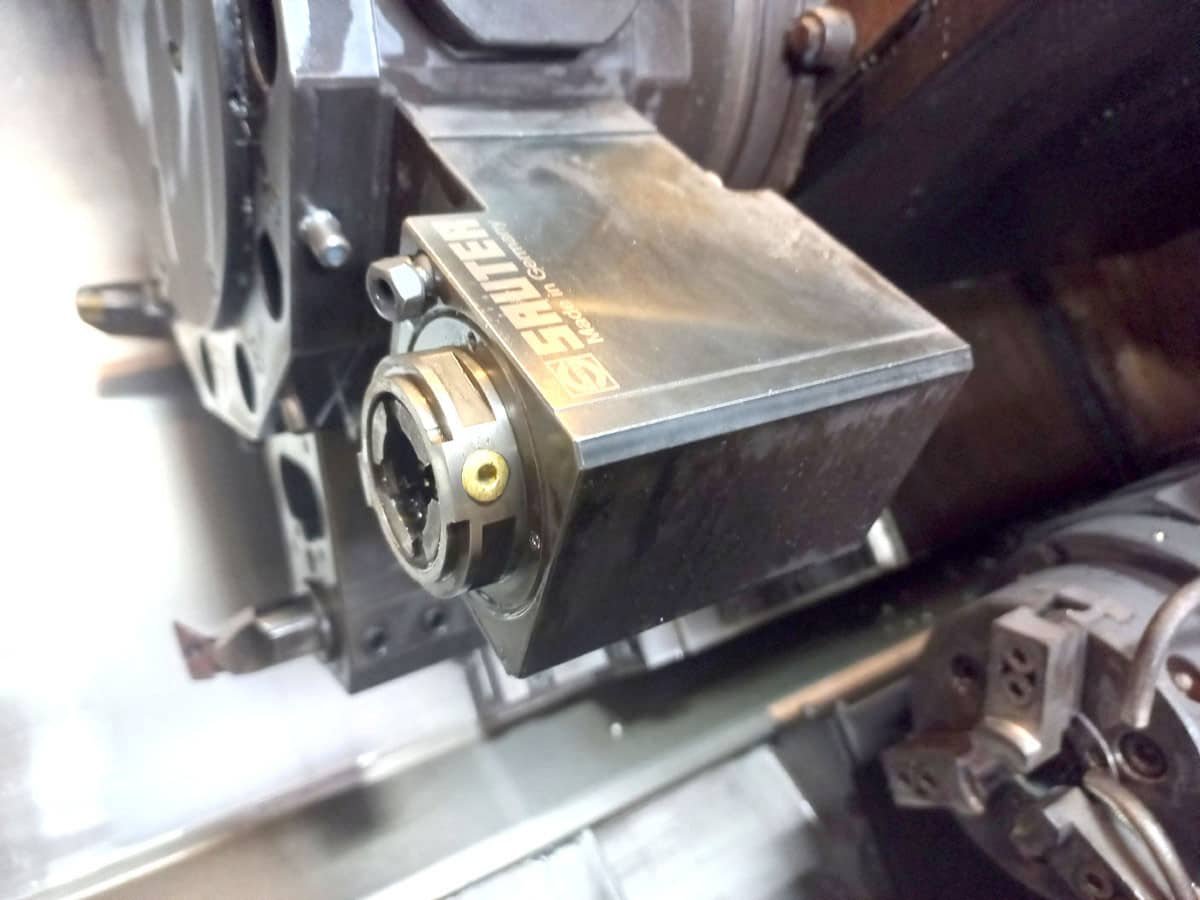

- driven tools

- toolholders (12 pcs.)

- driven toolholders (5 pcs.)

- 3-jaw hydraulic chuck

- tool head with hydraulic clamping

- X axis linear scale

- collet chuck

- set of collets

- coolant tank

- full guarding

- workspace illumination

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe