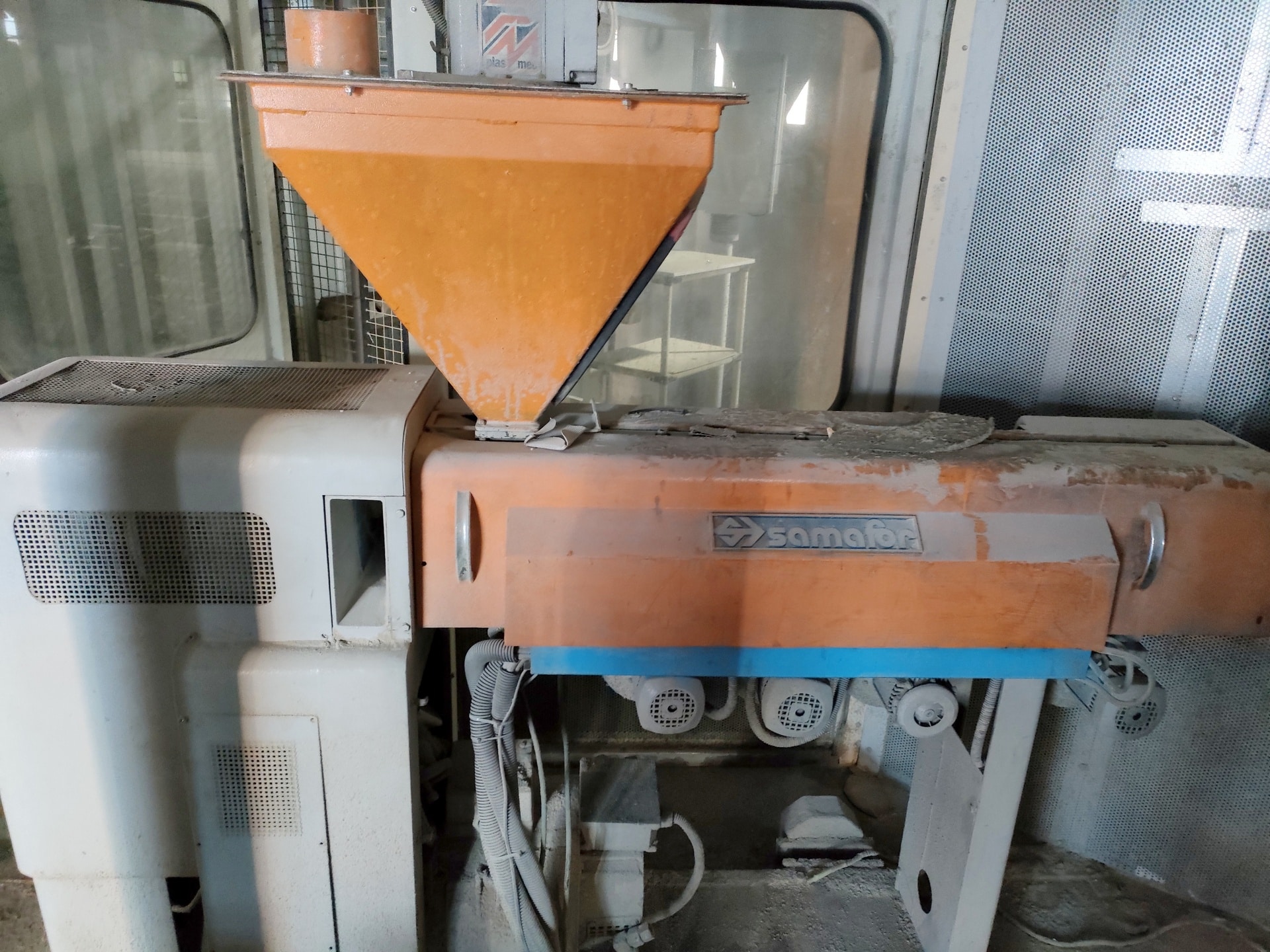

SAMAFOR EA 60 extruder was built in France in 1981. The machine which has a very rigid structure made of electrically welded thick steel plates, is used for processing any type of thermoplastic.

A reducer with three gears (reduction gears with parallel shafts), changed by means of shift wheels, is coupled to the high-speed shaft using a semi-flexible coupling. Circulation pumps with oil flow protection and a light signal on the control panel force continuous lubrication of the SAMAFOR EA60 extruder reducer. The light signal goes off when the pump or main motor stops.

The power section of the SAMAFOR extruder features an accurately centred cylinder with a flange for fixing with a set of easily accessible hardened screws. Electrical resistors housed in metal enclosures heat the cylinder and guarantee excellent heat transfer, thanks to the extensive contact surface. The cylinder is cooled by forced air circulation directed at a special zone controlled automatically by a temperature controller.

Components of the SAMAFOR EA 60 extruder

- motor

- screw

- cylinder

- reducer

- temperature regulator

- head and screen

- screw cooling

- control cabinet

- venting unit

- rotational speed measuring device

- air conditioning

- self-discharging supply hopper

- feed section and longitudinal bearing

- frame and base

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe