MYKOL TLM 3000 x 2000 thermoforming machine built in Italy in 2005, is designed for the thermal forming of plastic sheets (e.g. ABS, HIPS, PMMA) with a thickness of up to 10 mm. The thermoforming process results in the production of items such as e.g. tubs, containers and automotive parts. The machine has undergone many modifications over the past few years to improve safety, increase convenience of use and improve work performance.

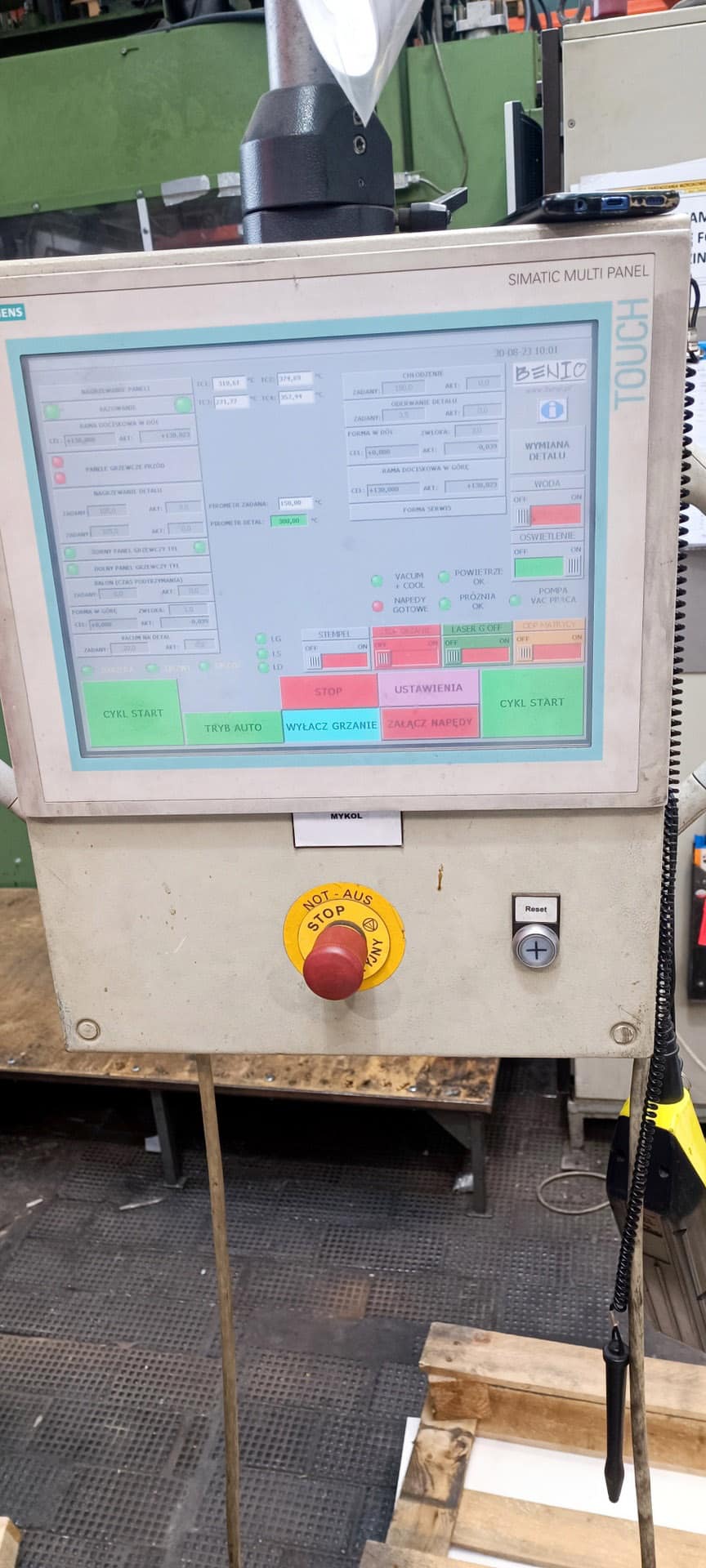

Thanks to the replacement of the old software with a new, more intuitive one, the extruder now offers the possibility of performing diagnostics and correcting programmes remotely from any location in the production hall. The operator also has at his disposal a remote control for machine operation with all the most important functions. The entire work area with a length of 3000 mm and a width of 2000 mm, has been protected by light curtains to increase user safety. The MYKOL 3000×2000 thermoforming machine also features a faster-acting vacuum system and reduction frames that change the size of the working window to a smaller size.

Technical data of the MYKOL TLM 3000 x 2000 extruder

- processed materials: ABS, HIPS, PMMA, etc.

- maximum mould thickness: 10 mm

- maximum mould height: 800 mm

- work space area (L x W): 3000 x 2000 mm

- maximum heating temperature: 800°C

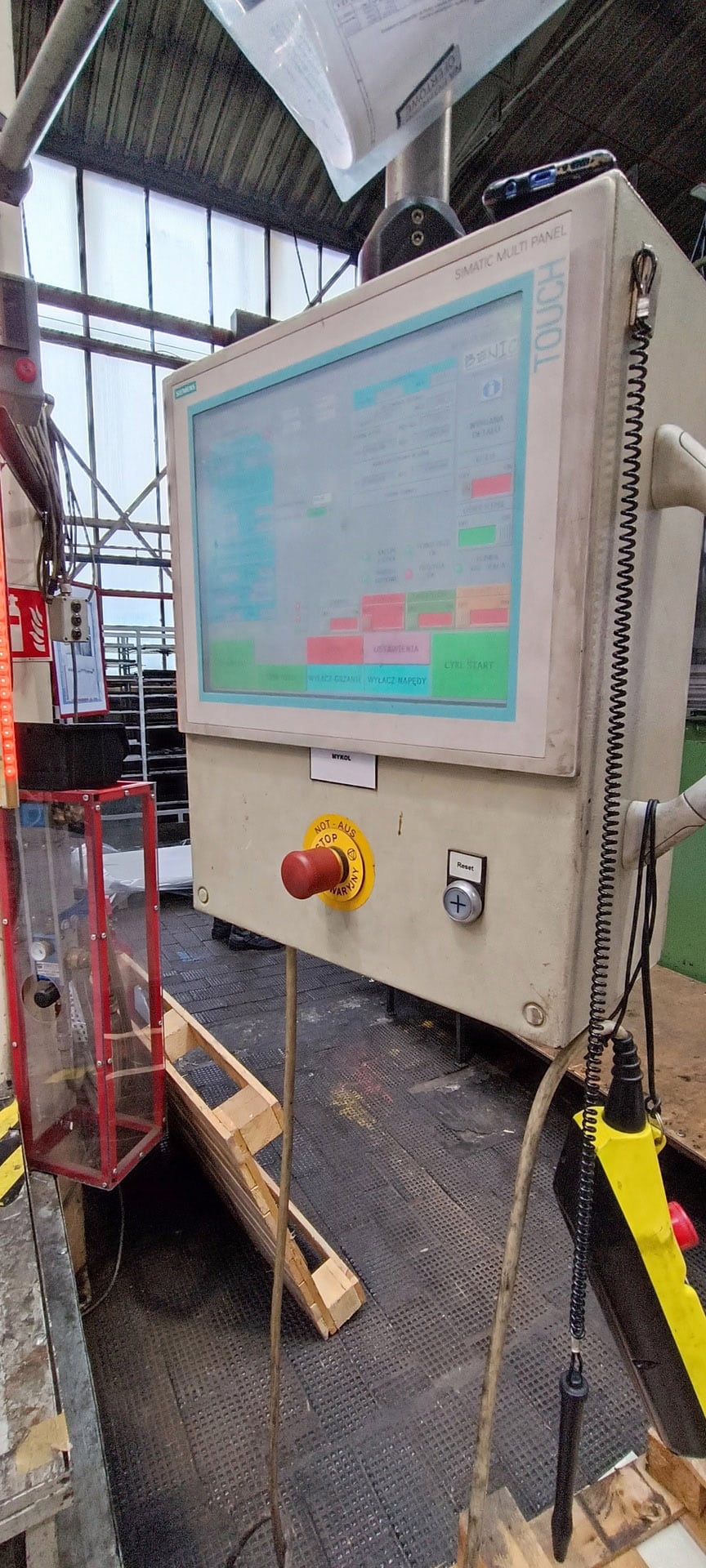

- HMI touch panel: SIEMENS SIMATIC MULTI PANEL TOUCH

- reduction frames (1300×1300, 1440×1440, 1710×1710, 1780×1260, 1930×1310, 2245×1195, 2245×1600, 3010×1235)

- top and bottom heating panels with ceramic heaters

- light curtains

- installed power: 240 kW

- maximum compressed air pressure: 8 bar

- minimum compressed air pressure: 6 bar

- cable inlet height: + 2,2 m

- supply: 3x 380 V; 50 Hz

- dimensions (L x W x H): 3900 x 6100 x 3500 mm + 1m (removable protruding gear rails)

- total weight of machine: approx. 4000 kg

The machine has undergone regular servicing and maintenance throughout its lifetime.

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe