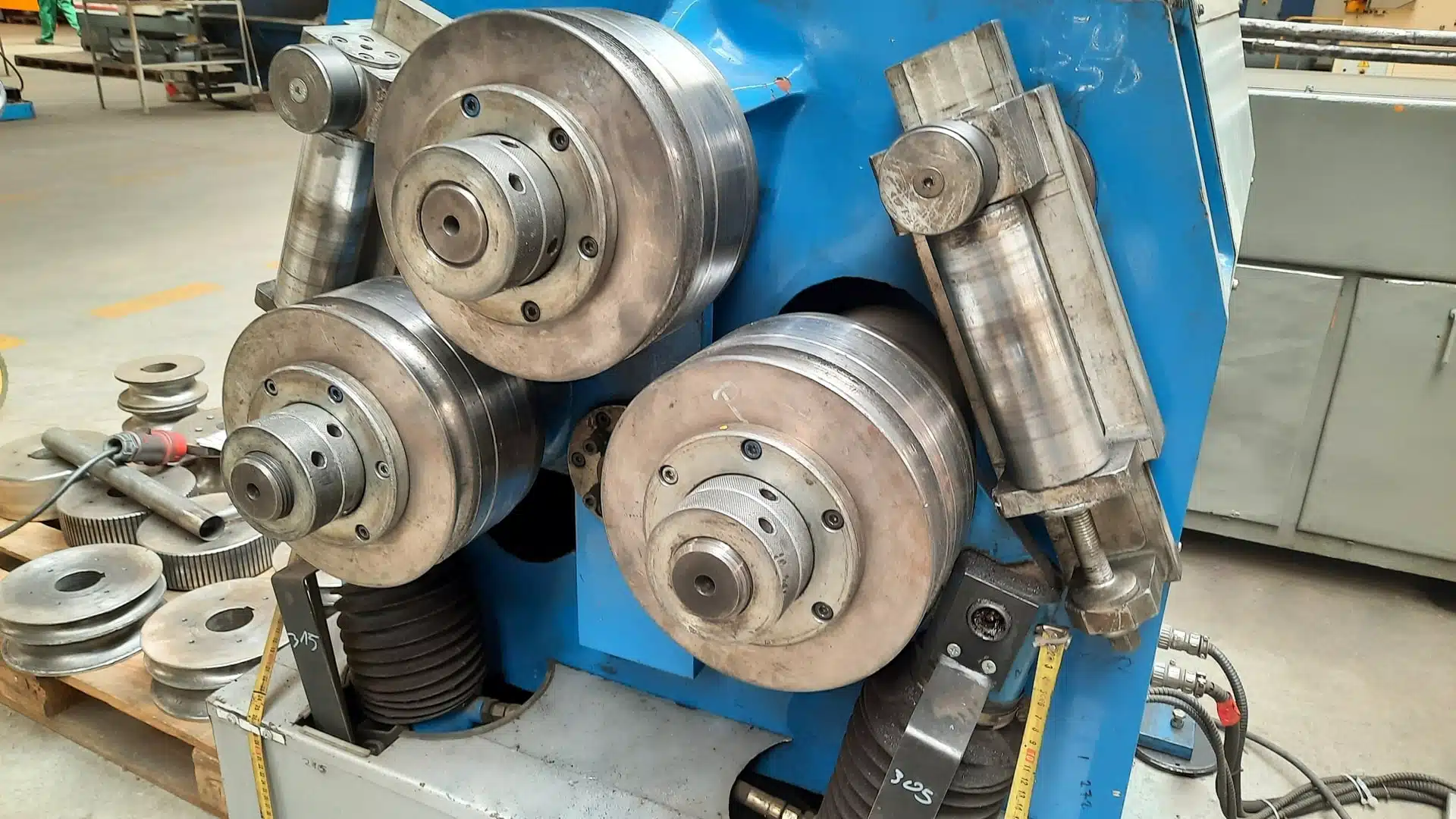

ACL W24Y-1000 profile rolling machine built in 2007 in China, is used in production facilities for a wide range of workpiece machining such as the production of circular components from angle bars and connecting flanges as well as the bending of angles and pipes of various lengths along a defined curve. Reliable and easy to operate, the machine is equipped with high-quality bearings and rollers to achieve the best possible bending quality.

The two lower rollers are driven by a gearbox whose output shaft is connected to two gear wheels. The vertical movement of the upper roller is controlled by a hydraulic cylinder, whose position is controlled by a special limiter which ensures that each element of the cycle is performed in the same way. The upper roller can be adjusted by an adjustment screw to change the radius of curvature of the workpiece. The W24Y-1000 profile rolling machine weighs 2500 kg.

Technical data of the ACL W24Y-1000 profile rolling machine

- number of rollers: 3

- maximum angle dimensions: 50 x 50 x 5 mm

- minimum diameter of angle bar: ø 450 mm

- rollers rotational speed: 11 rpm

- gearbox: BWD13-59-2,2

- hydraulic motor: Y90S-4

- hydraulic motor speed: 1400 rpm

- pump: YB-4

- pump power: 6.3 MPa

- adjustment screw

- front and rear guide slider

- foot control

- oil tank

- hydraulic motor power: 1.1 kW

- main motor power: 2.2 kW

- power supply: 415 V; 50 Hz

- weight of tube bending machine W24Y 1000: 2500 kg

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe