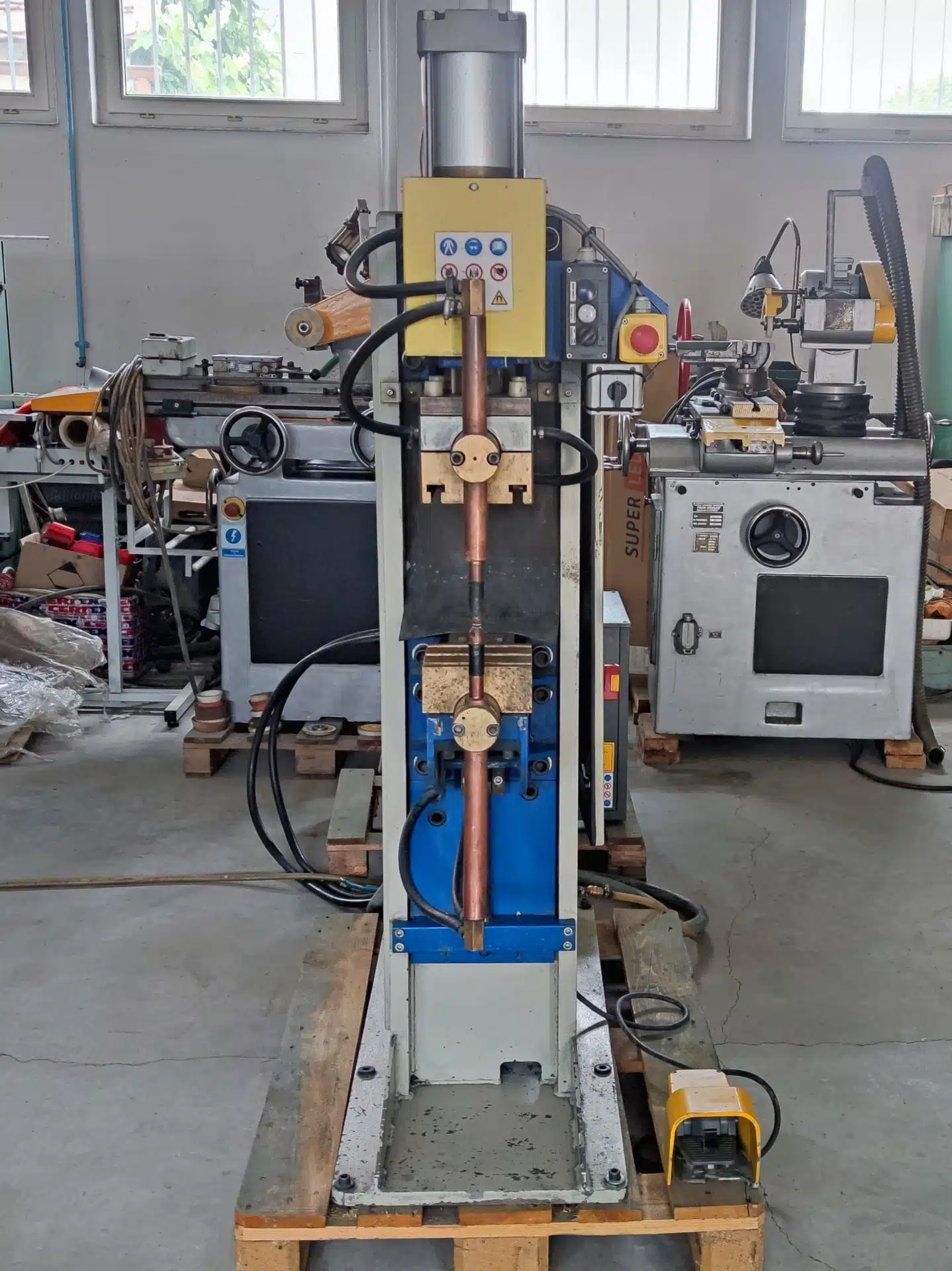

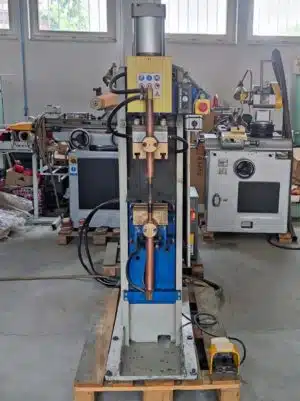

ASPA ZPm-80 spot welding machine manufactured in 2015 in Poland, is designed for resistance spot or projection welding of workpieces made of among others aluminium, stainless steel, brass and black steel. During the process, the machine heats two metal sheets of a maximum thickness of 6 mm until they reach a plastic state in order to join them into an inseparable whole after cooling. The joining of the workpieces is performed by electrodes through which pass a maximum current of 191 kVA for spot welding or 197 kVA for projection welding. The ZPM-80 spot and projection welding machine is equipped with an OMI CHW M21 chiller for electrode cooling, foot control and electrodes. The total weight of the machine is 690 kg.

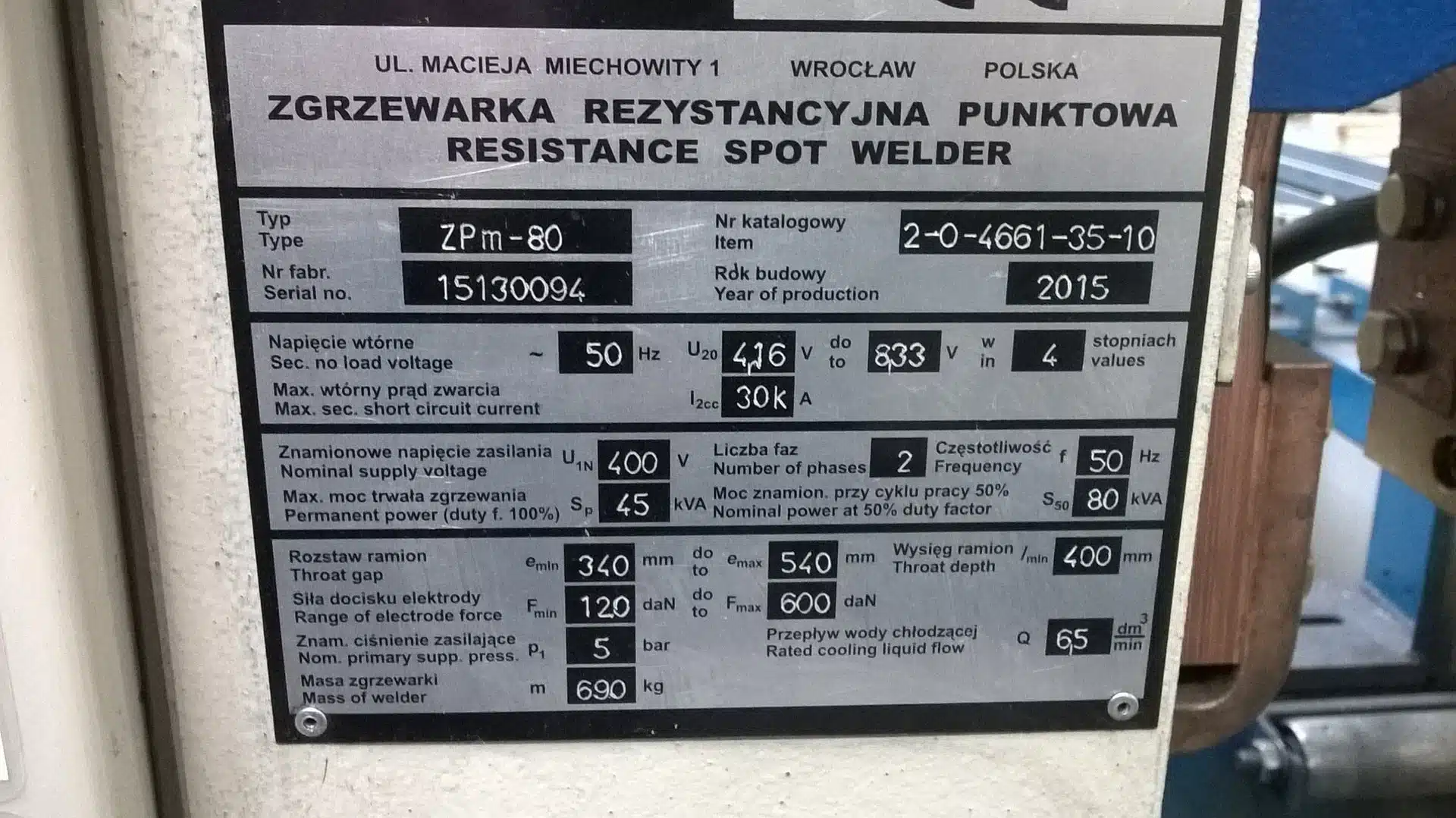

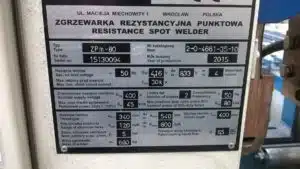

Technical specifications of the ASPA ZPm-80 welding machine

- processed materials: steel, stainless steel, aluminium, aluminium alloys, brass, nickel alloys, chromium alloys, heat-resistant steel alloys, galvanised sheets, round steel bars

- maximum workpiece thickness (steel): 6 mm

- maximum workpiece thickness (stainless steel): 2 mm

- maximum workpiece thickness (heat-resistant steel): 2 mm

- maximum workpiece thickness (galvanised steel sheet): 2 mm

- maximum workpiece thickness (nickel/chrome alloy): 2 mm

- maximum workpiece thickness (brass): 1,5 mm

- maximum workpiece thickness (aluminium and its alloys): 1.2 mm

- arm spacing range: 340-540 mm

- arm reach (spot welding): 400 mm

- arm reach (projection welding): 280 mm

- maximum spot welding power: 191 kVA

- maximum projection welding power: 197 kVA

- secondary short-circuit current (spot welding): 29 kA

- secondary short-circuit current (projection welding): 30 kA

- maximum spot welding current: 23.2 kA

- maximum projection welding current: 24 kA

- maximum electrode clamping force: 600 daN

- minimum electrode clamping force: 120 daN

- bottom extension arm diameter: 63 mm

- electrode plug holder diameter: 32 mm

- electrode taper: 19 mm

- machine taper: 1:10

- working stroke: 75 mm

- maximum secondary short-circuit current: 30 Ka

- maximum permanent welding power: 45 kVA

- rated power at 50% duty cycle: 80 kVA

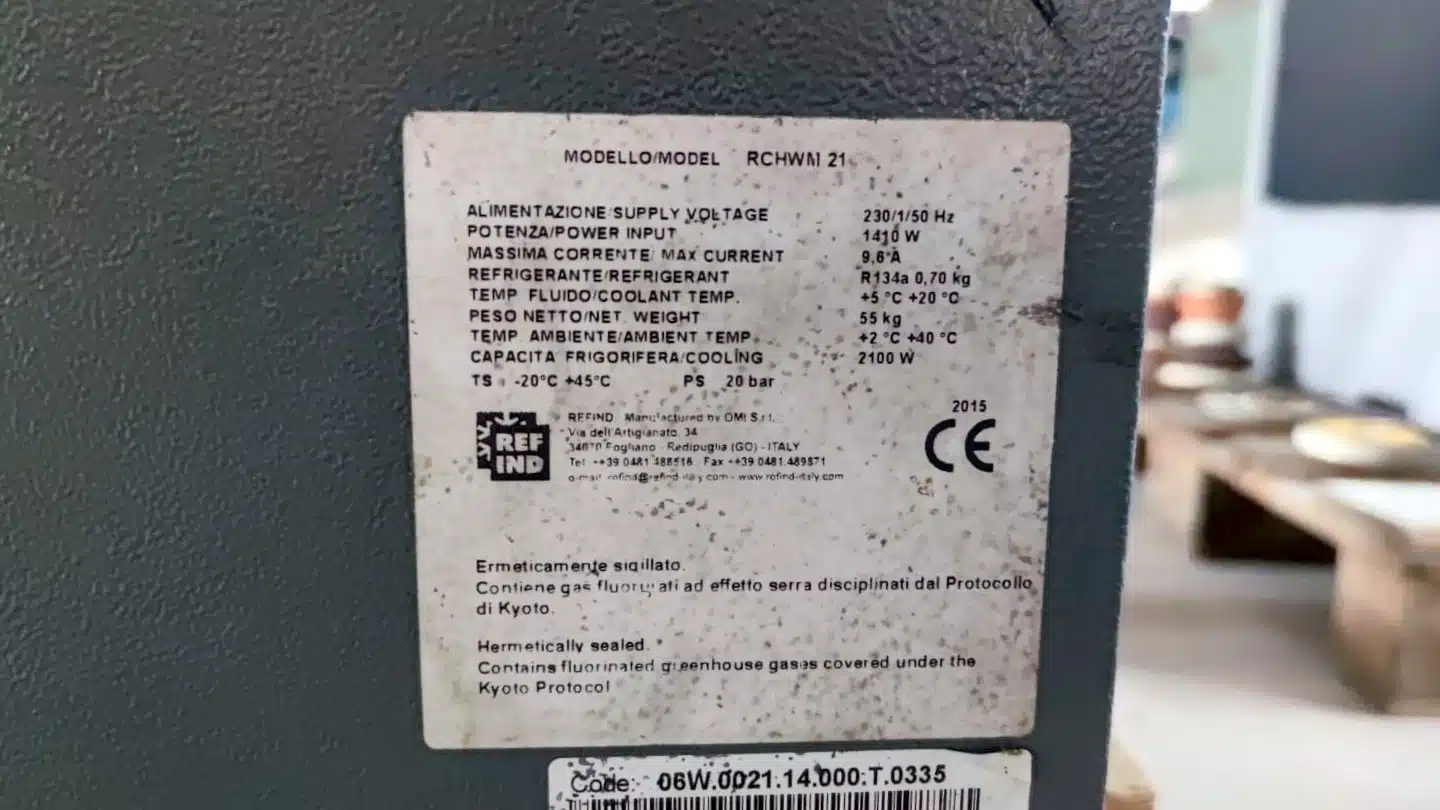

- chiller cooling power: 2100 W

- cooling water flow: 6.5 dm3/min

- maximum cooling water pressure: 4 bar

- minimum cooling water pressure: 2 bar

- compressed air consumption (1000 spot welds at 5 bar, maximum working stroke and ø 125 mm cylinder): 20 m3

- maximum compressed air pressure: 5 bar

- minimum compressed air pressure: 1 bar

- minimum water consumption at rated power: 390 l/h

- delayed fuses: 250 A

- hose diameter (input/output): 8 mm

- minimum internal diameter of hoses: 10 mm

- cross-section of network cables for L=10m: 2×70+35 mm2

- cross-section of network cables for L=30m: 2×95+50 mm2

- power supply: 2x 400 V; 50 Hz

- weight of welding machine ZPm 80: 690 kg

Equipment of ASPA ZPm 80 projection welding machine

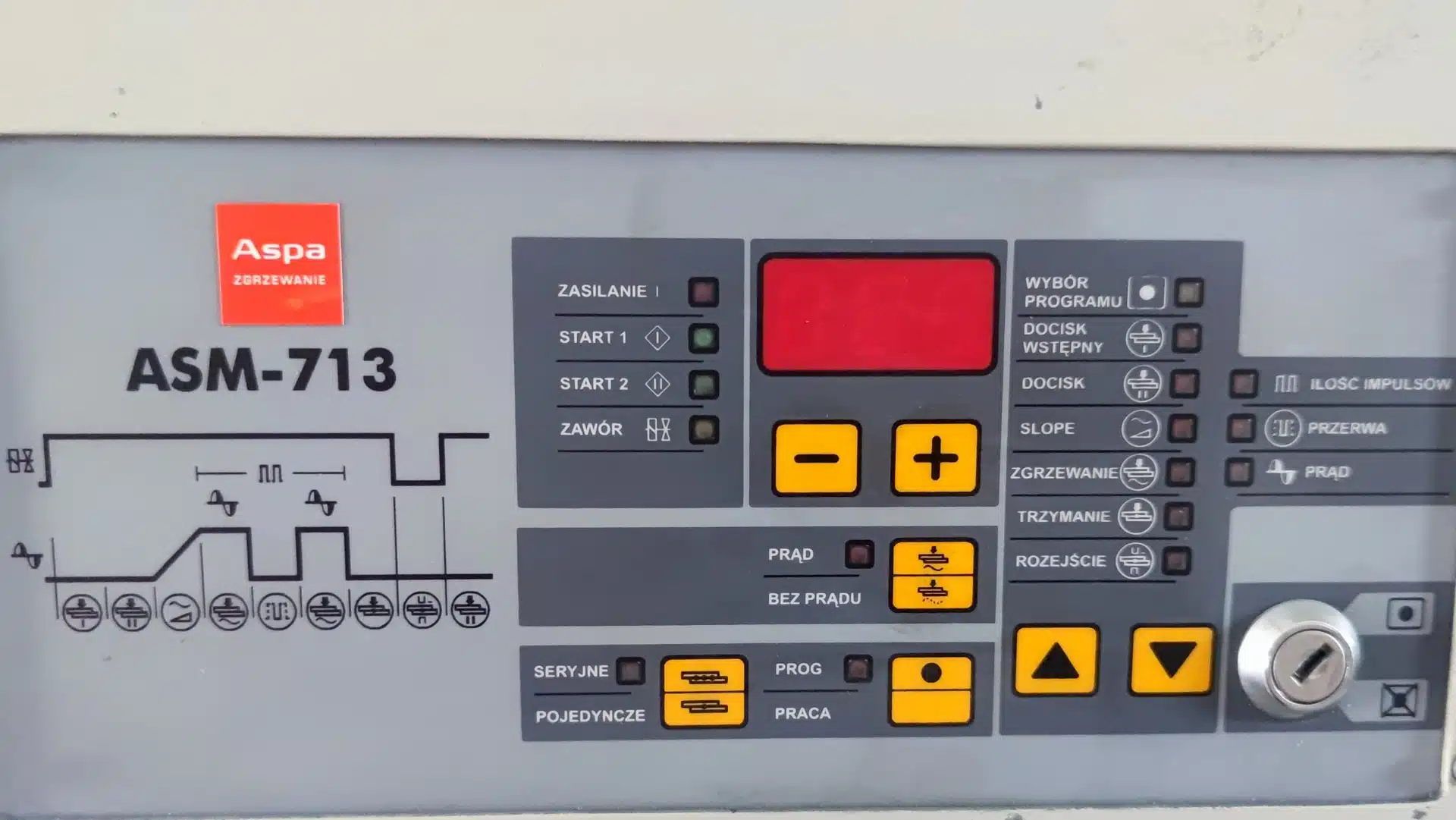

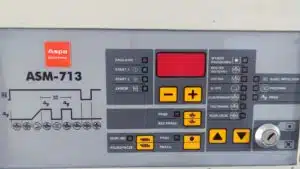

- control unit: ASPA ASM-713

- chiller: OMI CHW M21

- 20 pieces of electrodes (10 sets)

- foot control

- technical documentation

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe