BENTELER tecGrinder glass bevelling machine was built in 2005 in Germany. The machine which consists of a grinding station, a polishing station and a washer is used for simultaneous grinding and polishing of parallel glass edges with a maximum thickness of 21 mm. The glass grinding machine features a state-of-the-art SIEMENS controller, which allows the grinding parameters to be programmed easily and conveniently.

The glass processing process begins with the automatic adjustment of the height and width of the glass sheet using corrosion-resistant linear guides, pressure beams and top apertures. In order to eliminate backlash, the control system performs a direct movement to the final position without slowing down the reverse movement. After adjustment, the workpieces are moved between the processing stages using a special conveyor with four synchronised toothed belts.

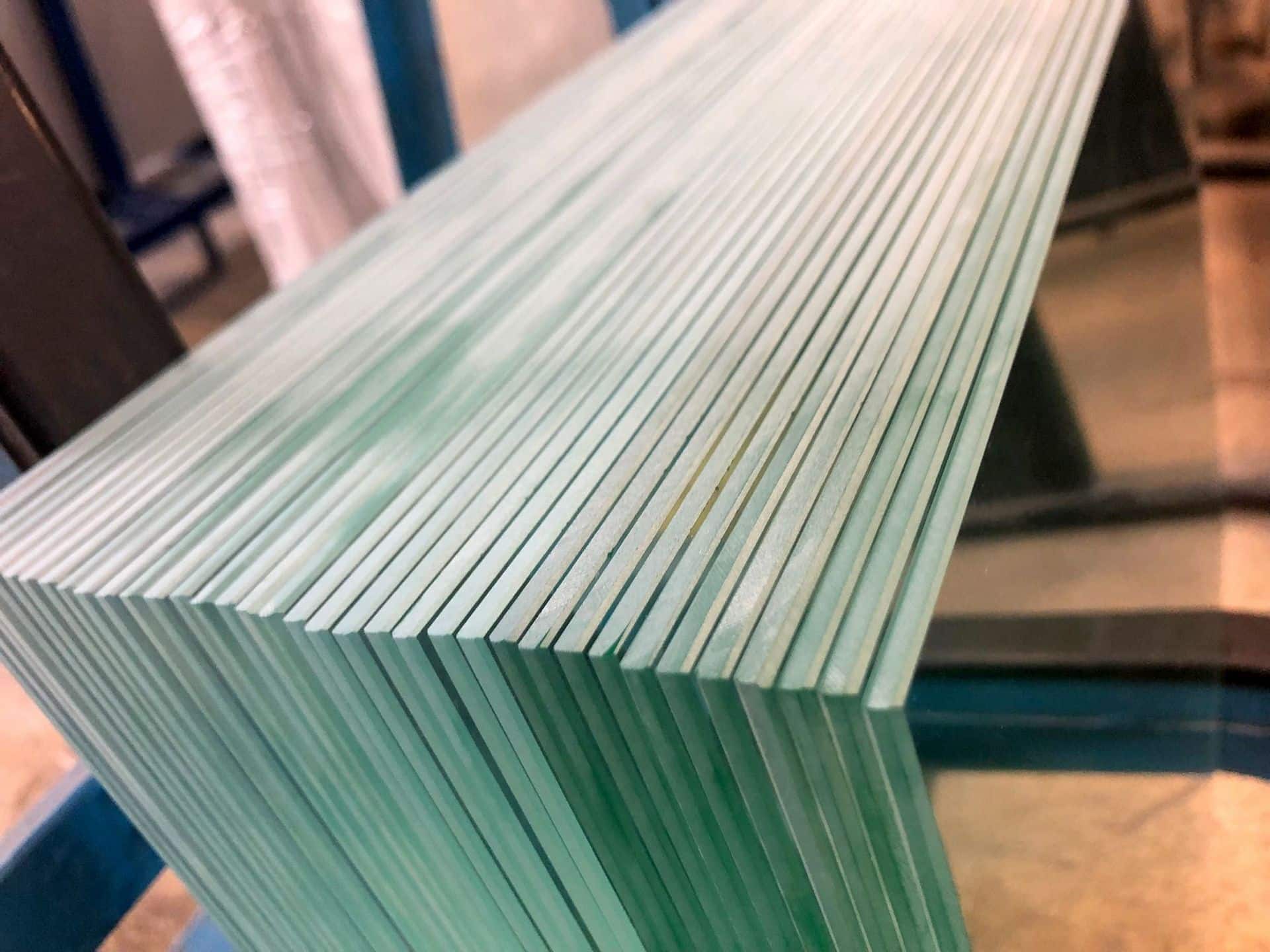

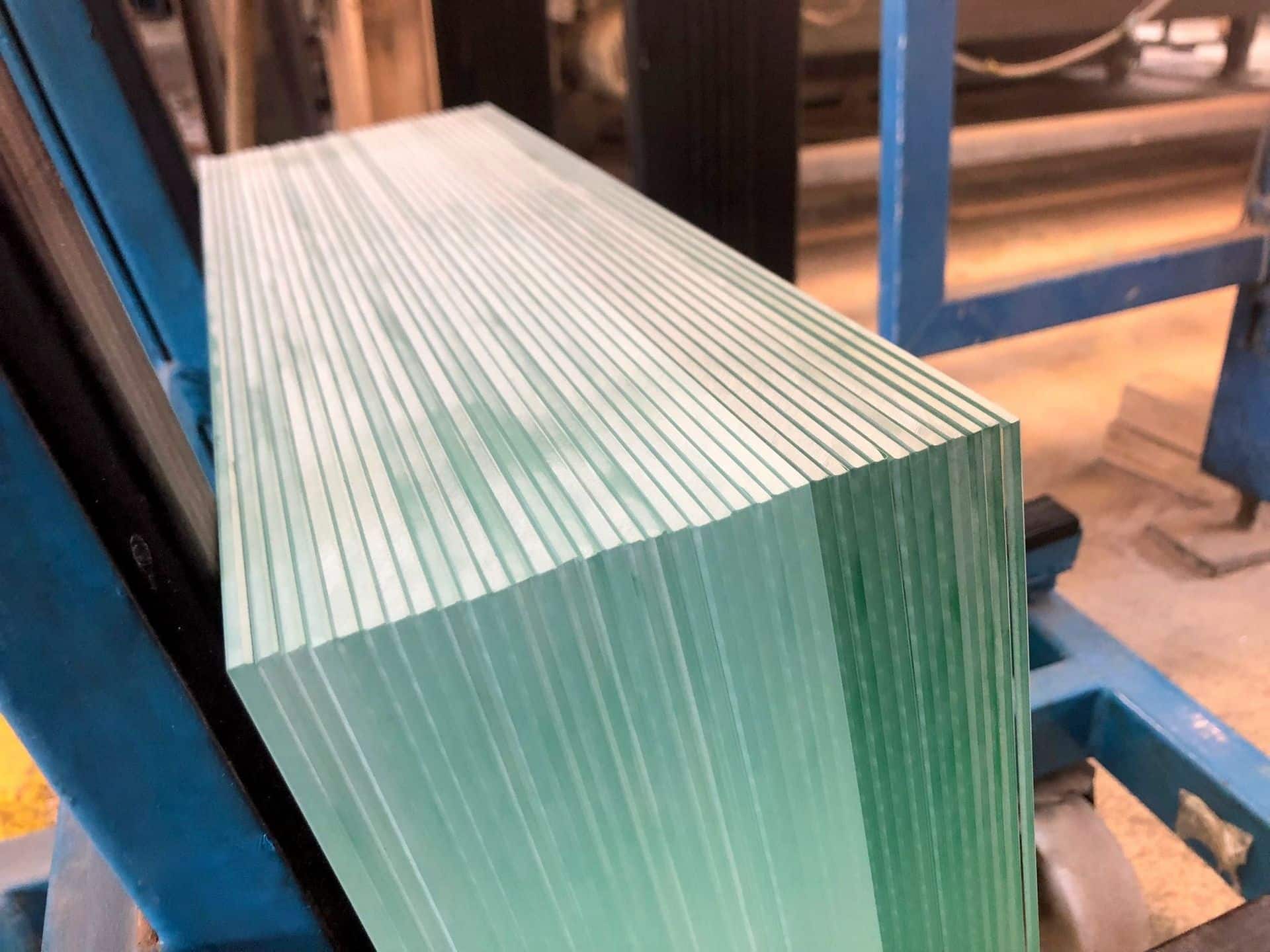

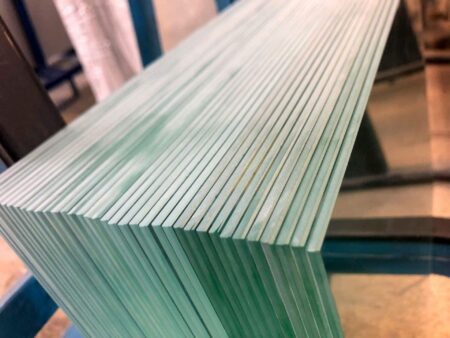

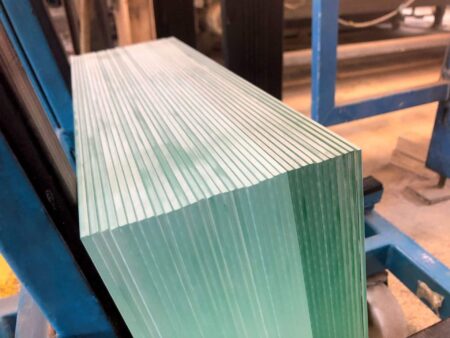

The glass is firmly clamped along the entire length of the double-edging machine for glass by pressure belts fitted with a flexible pressure profile. Each conveyor belt is driven individually by a synchronised motor. The grinding station of the glass grinding machine performs precise edge processing by using high-precision BENTELER grinding spindles with sliding rotors, powered by low air pressure to ensure long-lasting protection from coolant.

The construction of the grinding station is characterised by its high rigidity and is designed to prevent penetration of coolant into the machine frame and grinding spindles. Once this stage is complete, the processed glass is polished by precision spindles with diamond and cup wheels. The pneumatically-generated pressure of the polishing wheels is transferred almost frictionlessly through the linear positioning of the rotor, resulting in a gentle feed and accurate pressure.

Finally, the workpieces are transferred to the washing machine BENTELER tecWasher, designed to thoroughly wash and dry the workpiece. The washer is equipped with a SIEMENS S7 PLC controller for controlling the internal processes of the machine. The glass grinding machine with glass washer guarantees highly efficient operation and excellent processing quality.

Technical specifications of the BENTELER tecGrinder glass grinding machine

- control system: SIEMENS

- servo drives: SIEMENS

- maximum glass thickness: 21 mm

- minimum glass thickness: 3 mm

- maximum glass length: 2500 mm

- minimum glass length: 250 mm

- maximum glass width: 1500 mm

- minimum glass width: 180 mm

- working speed: depends on the thickness of the glass

- rotational speed of edge grinding station: approx. 2800 rpm

- rotational speed of edge polishing station: approx. 2800 rpm

- diamond polishing wheels diameter: 175 mm

- cup polishing wheels diameter: 170 mm

- diameter of peripheral diamond polishing wheels for grinding glass edges: 50 mm

- maximum width adjustment speed: 30 m/min

- conveyor speed: 1-15 m/min

- pressure bar adjustment: 180/30 mm/min

- number of coolant pumps: 2

- volume of coolant pumps: each 280 l/min at 1 bar

- compressed air pressure: 6 bar

- noise level: 80 ± 2 dB(A)

- power supply: 3x 400 V; 50 Hz

- tecGrinder machine length: 4100 mm

Technical data of the BENTELER tecWasher glass washing machine

- PLC control: SIEMENS S7

- glass thickness range: 1.5-12 mm

- maximum glass width: 1000 mm

- cleaning speed: 13 m/min

- reference line: right-hand side

- minimum glass width on reference line: 50 mm

- minimum glass length on reference line: 148 mm

- length of washing section: 592 mm

- length of drying section: 693 mm

- length of spray section: 296 mm

- diameter of rollers: 40 mm

- diameter of brushes: 110 mm

- conveyor speed: 5-15 m/min

- height of conveyor: 850 ± 25 mm

- compressed air pressure: 6 bar

- power consumption: 51 kVA

- noise level: 80 ± 2 dB(A)

- power supply: 400 V; 50 Hz

- tecWasher machine dimensions (L x H): 1581 x 1800 mm

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe