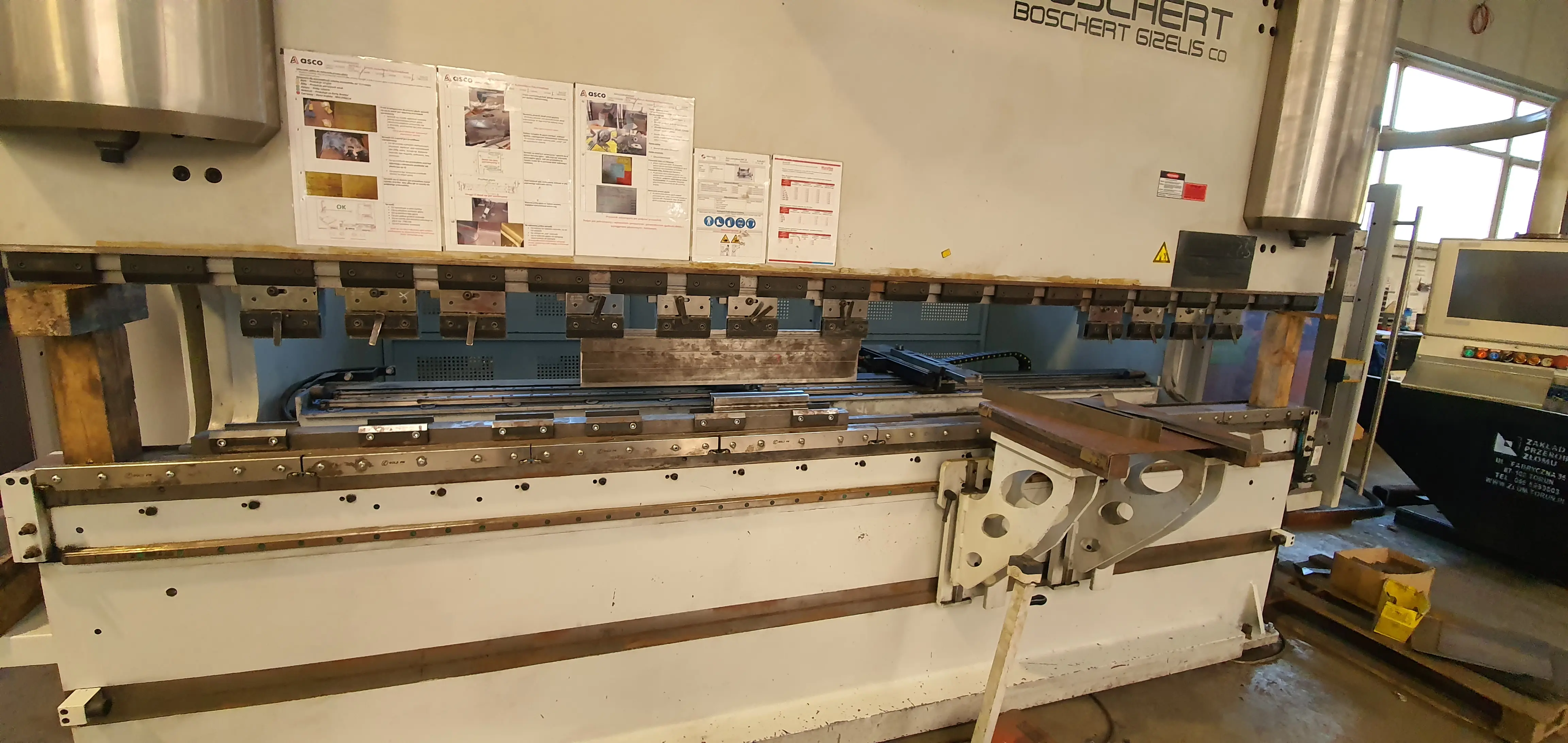

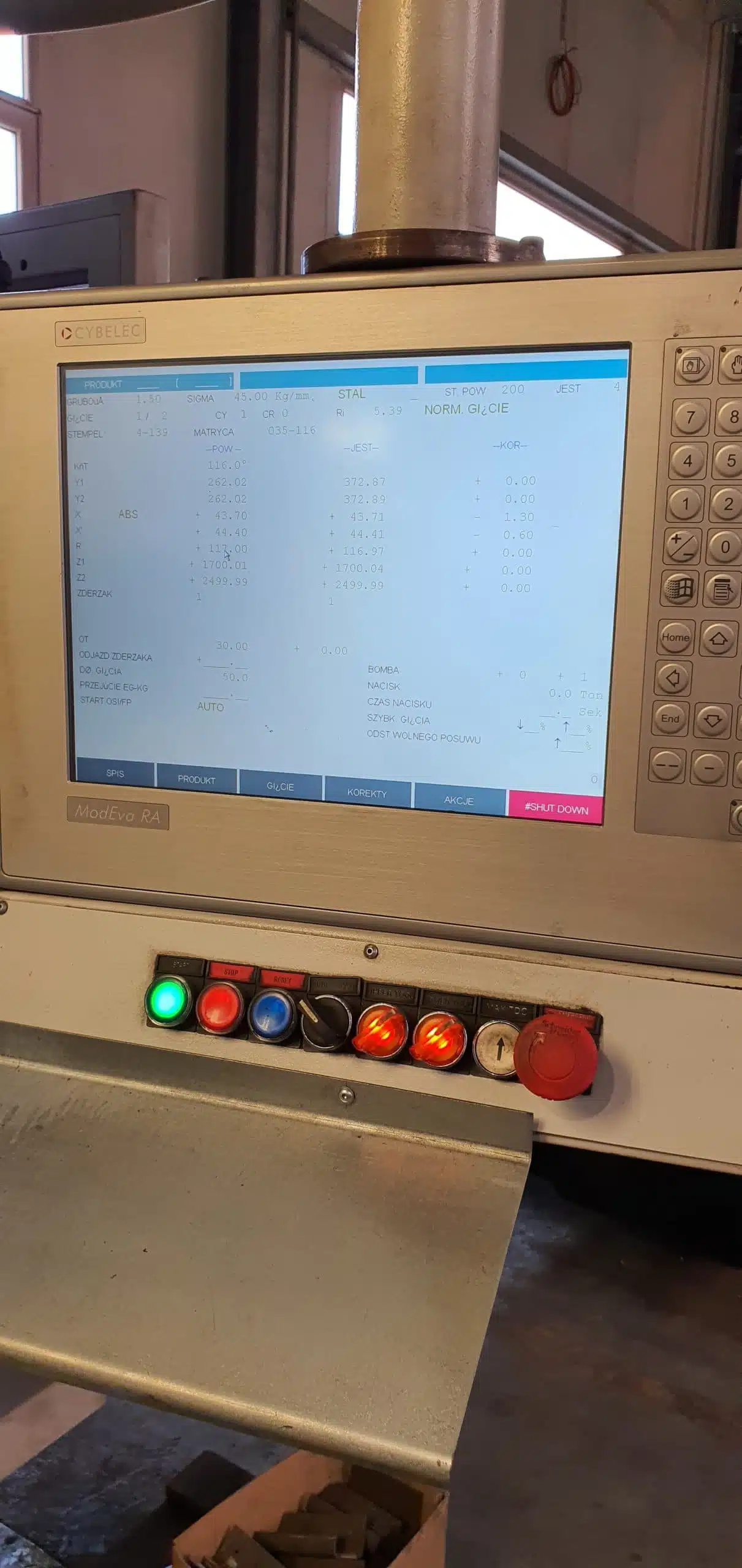

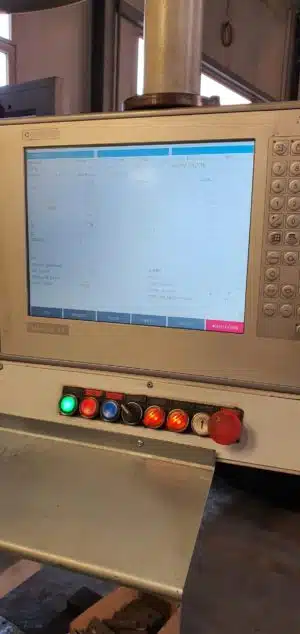

BOSCHERT GIZELIS G-BEND 4240 CNC press brake was produced in 2015. The machine is equipped with a Cybelec 60 CNC control, which, combined with a multi-axis stop, ensures automation and high repeatability of bends performed. The machine quickly and accurately carries out pre-programmed bends with a pressure of up to 240 tons. The press is most often used in industrial plants and factories that deal with medium-series production.

Technical parameters of the BOSCHERT G Bend 4240 press

– bending length: 4100 mm

– pressure: 240 t

– distance between the body walls: 3550 mm

– projection 400 mm

– ground clearance: 515 mm

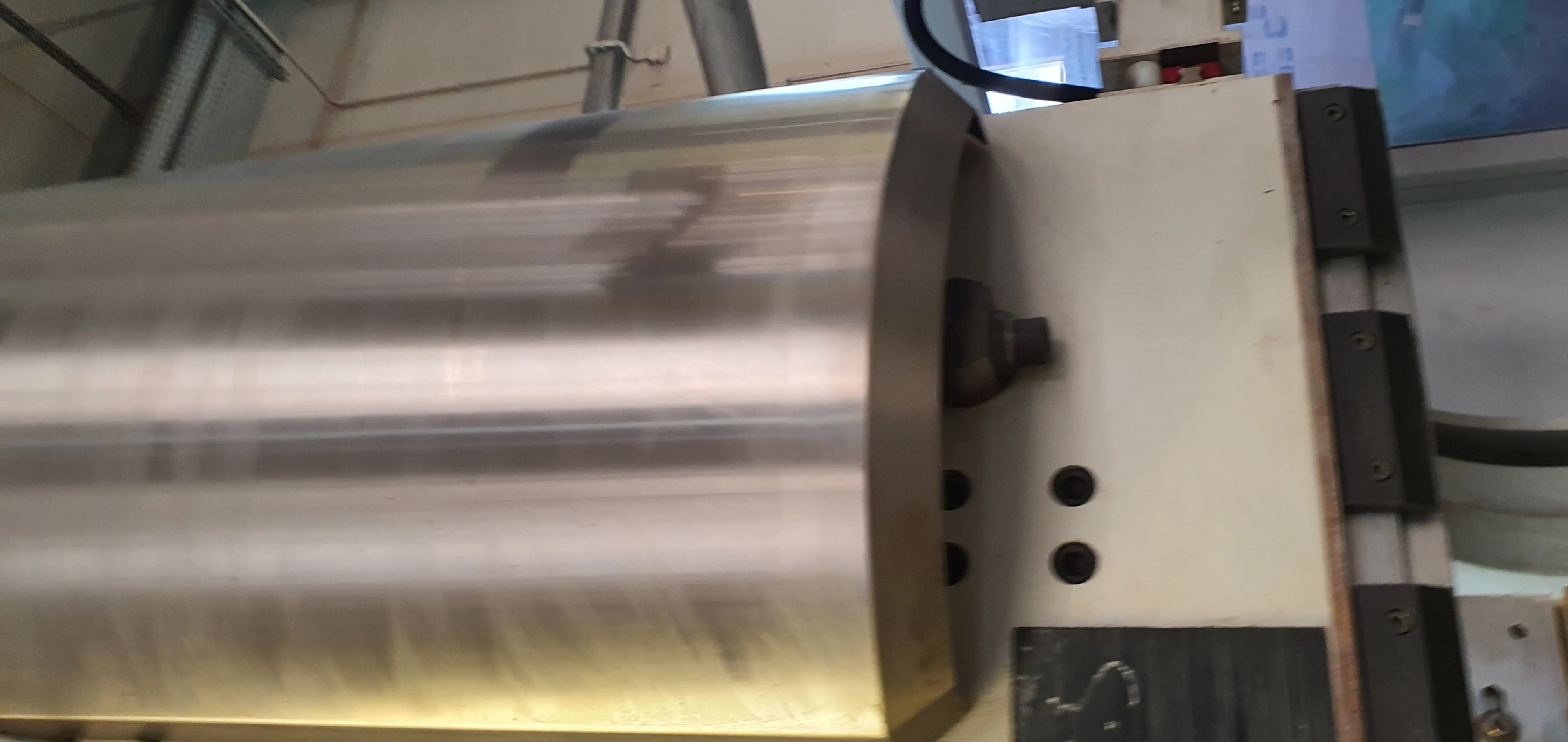

– ram stroke: 250 mm

– table width: 80 – 220 mm

– rapid speed: 0 – 180 mm / sec

– working speed: 0-10 mm / sec

– lifting speed: 0-130 mm / sec

– max. hydraulic pressure: 275 bar

– main engine power: ~ 26 kW

– weight: ~ 22 t

Equipment for the press brake BOSCHERT GIZELIS G-BEND 4240

– hour meter reading: 4859 h

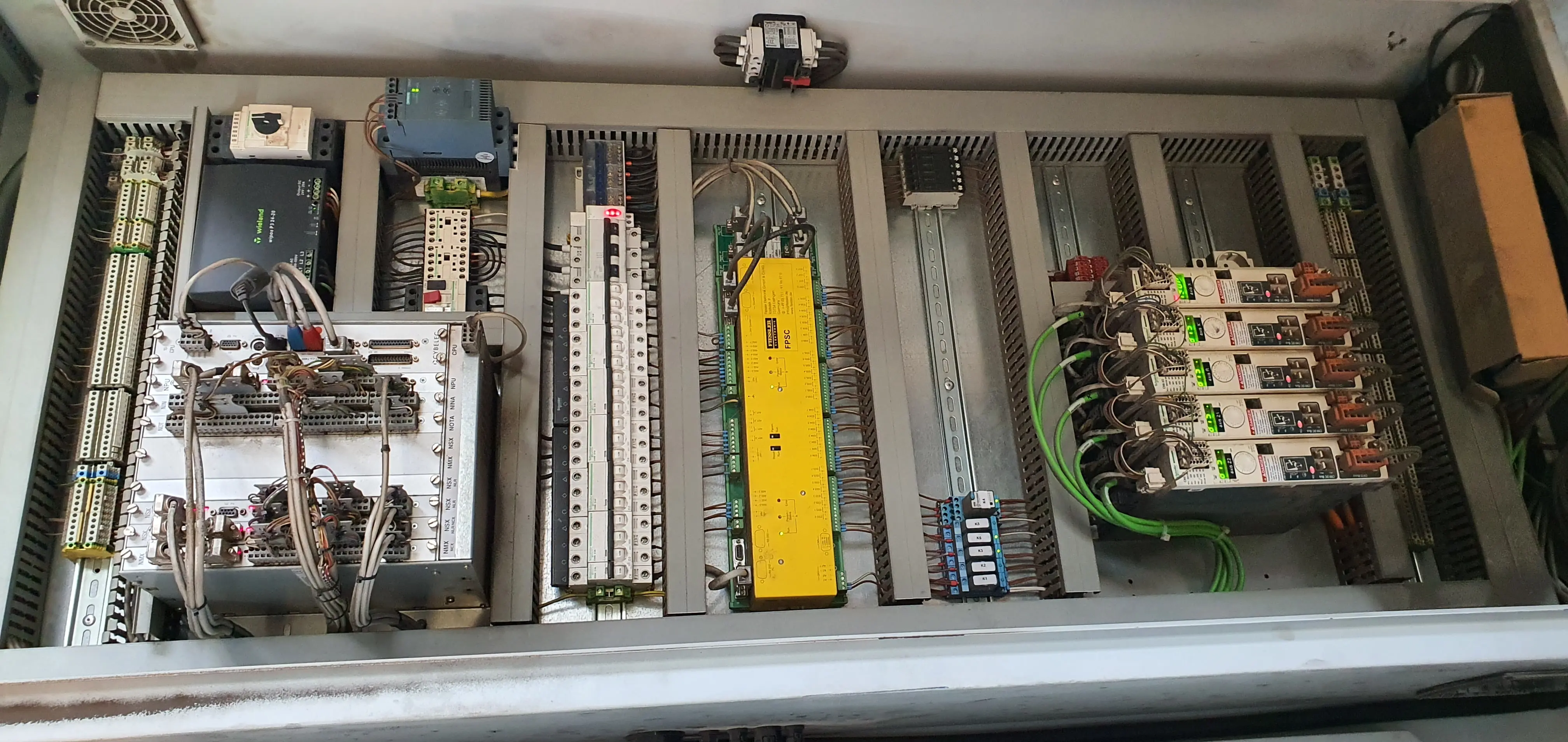

– CNC control: Cybelec DNC 60 (additionally from a computer)

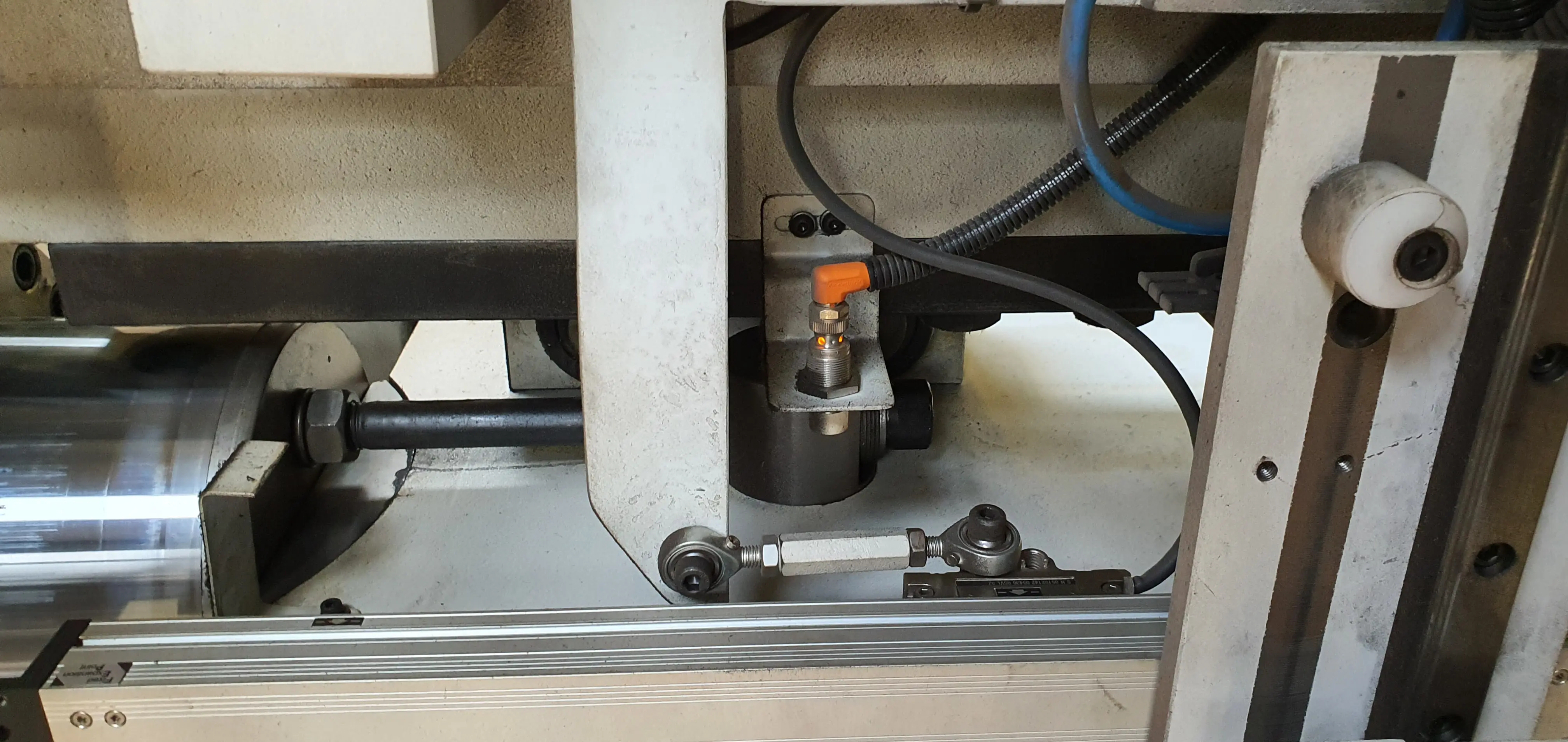

– Y1, Y2 independent hydraulic actuators, proportional valve technology

– additional welded frame on the sides

– efficient, quiet and precise BOSCH REXROTH hydraulic system

– piston guide with double roller bearings on each side

– rigid and stable structure

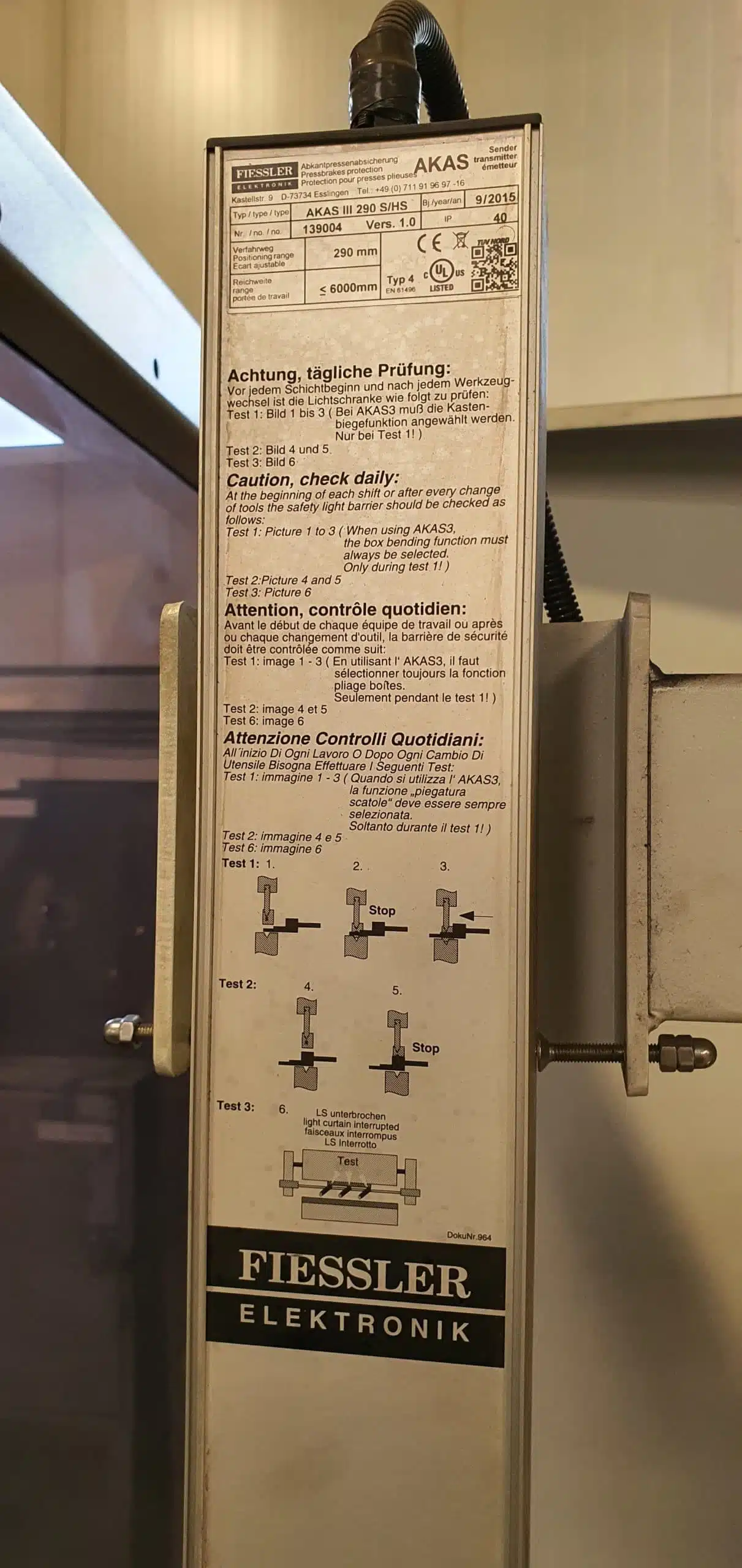

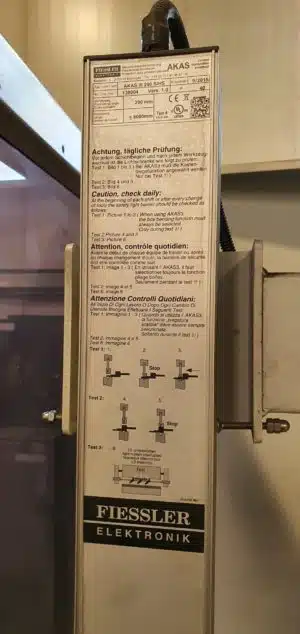

– optical safety barriers

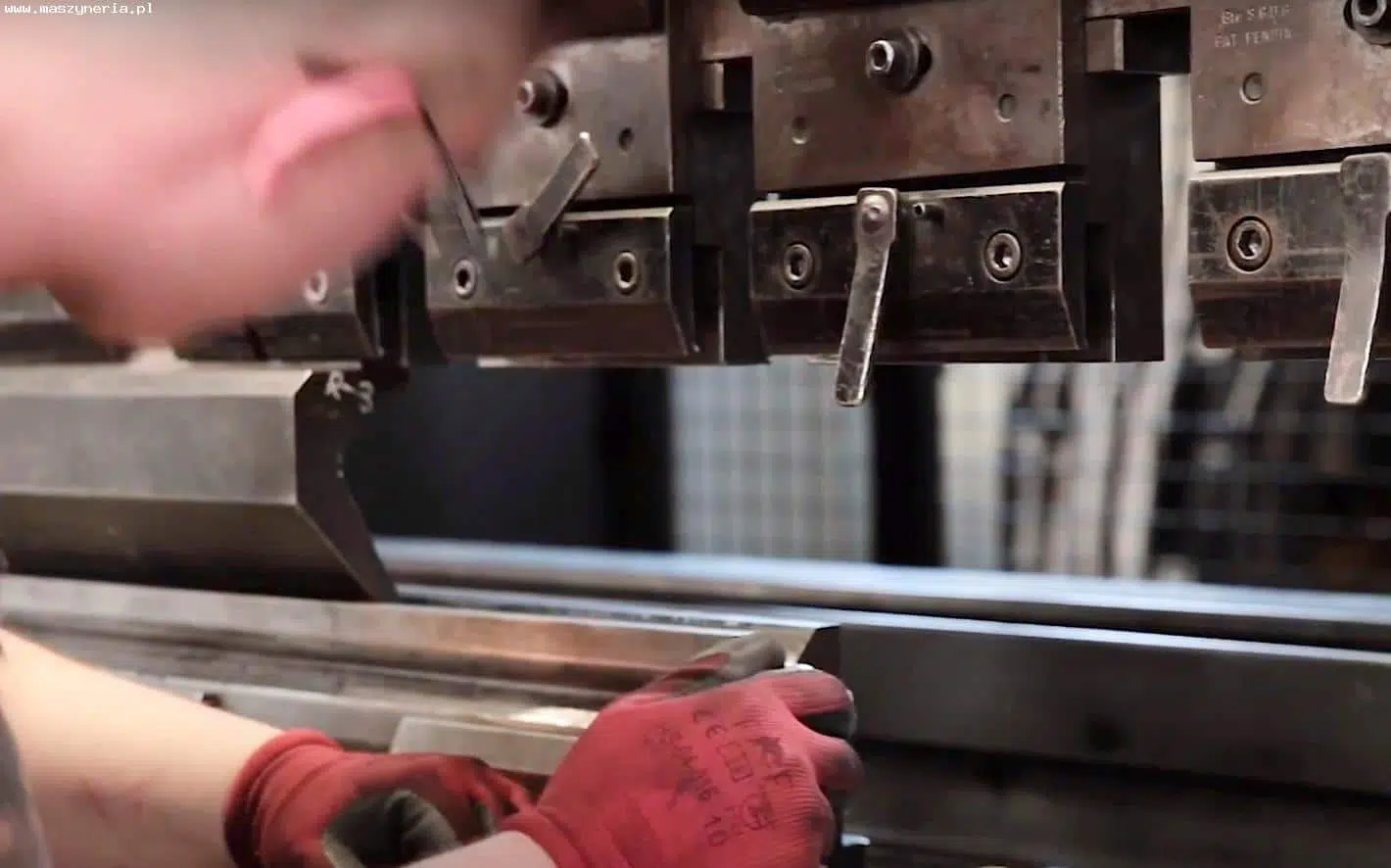

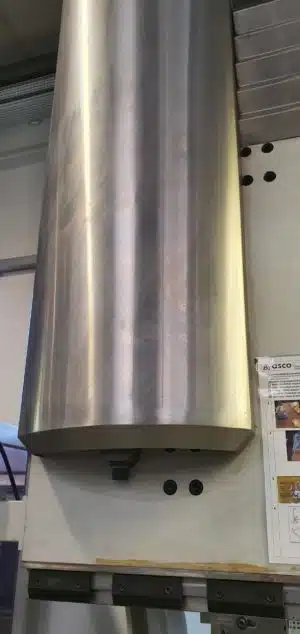

– BOSCHERT GIZELIS G-Bend 4240 bending clamps: ROLLER