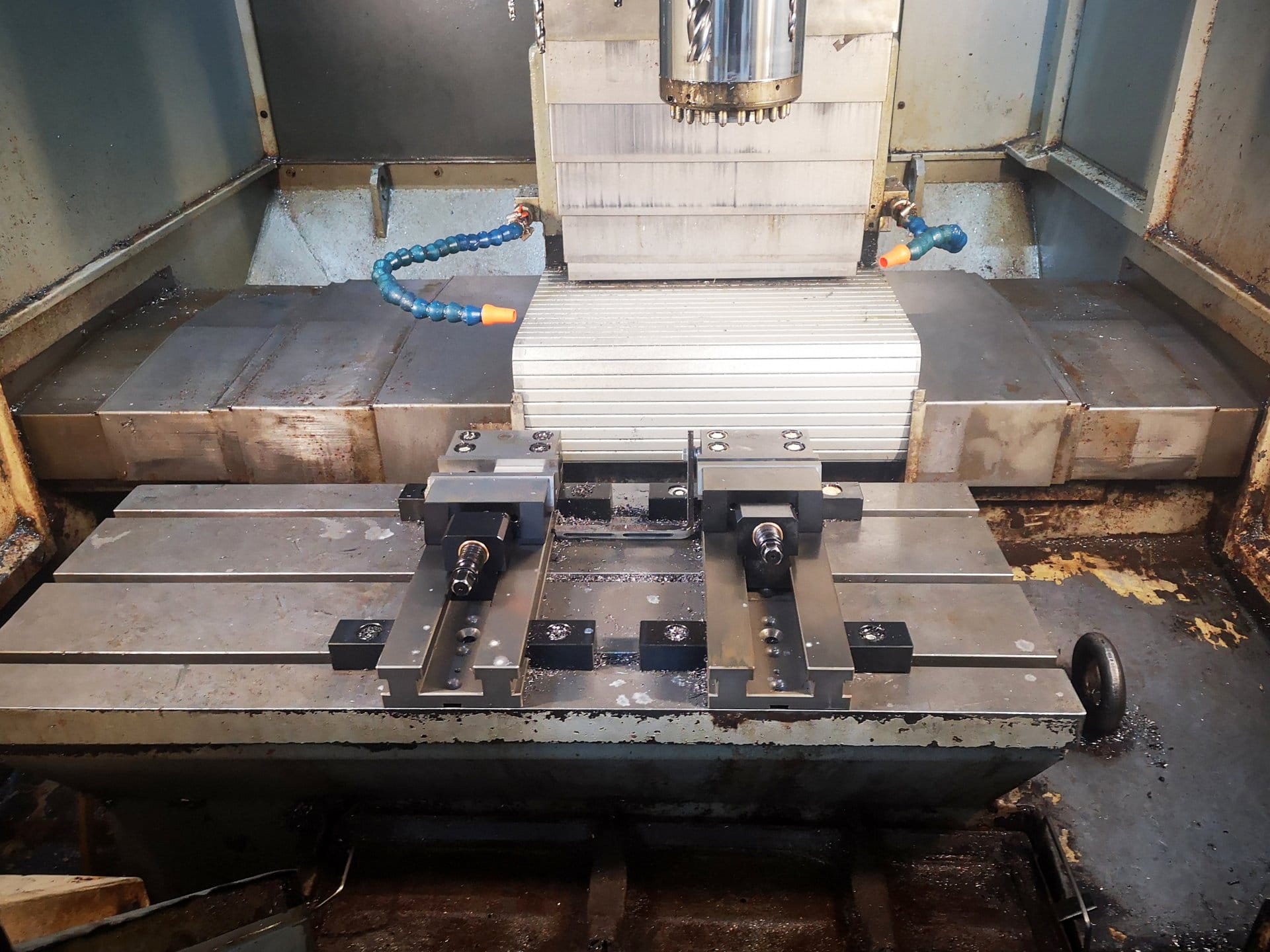

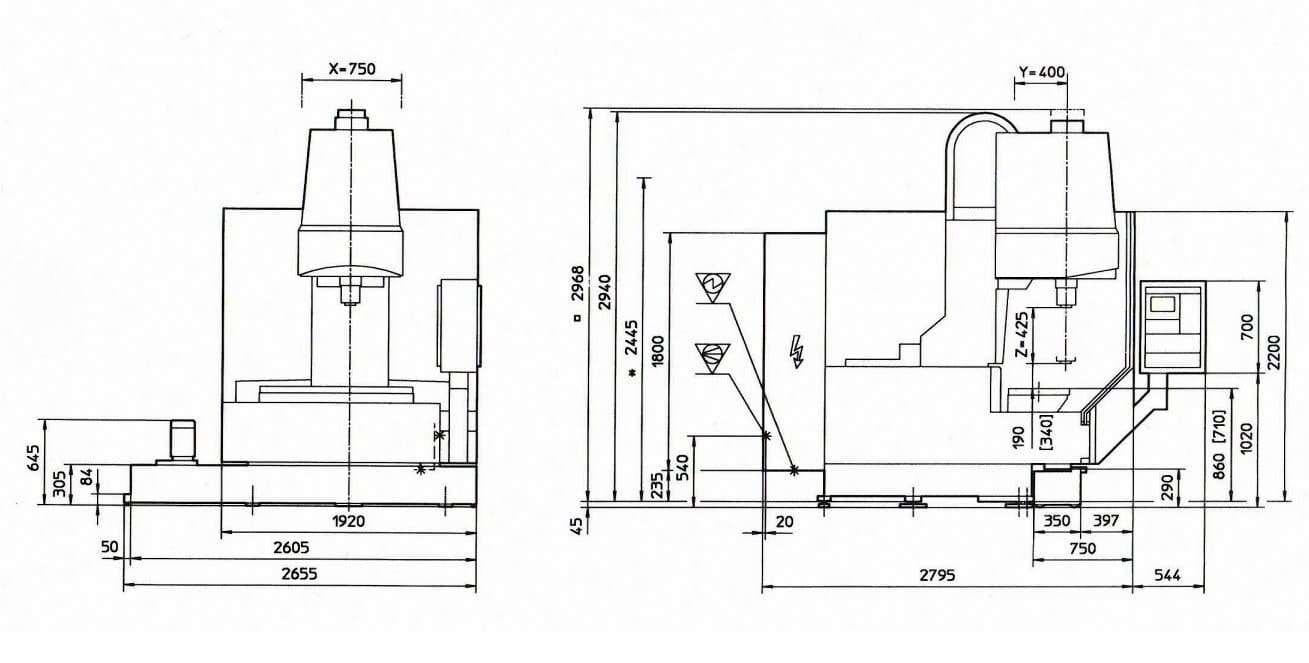

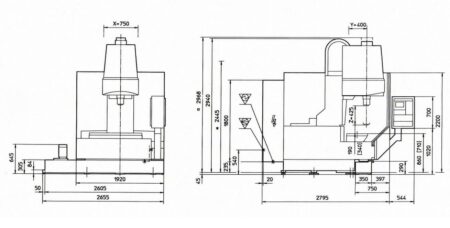

CHIRON FZ 18 S MAGNUM vertical machining centre, built in 1997 in Germany, is designed for precision workpiece machining. Machining is performed on a working table with dimensions (L x W) 1150 x 460 mm, in three axes (X,Y,Z) with feeds of 750 mm (X axis), 400 mm (Y axis) and 425 mm (Z axis). In the past, the milling centre has been used for machining structural steel, stainless steel and aluminium.

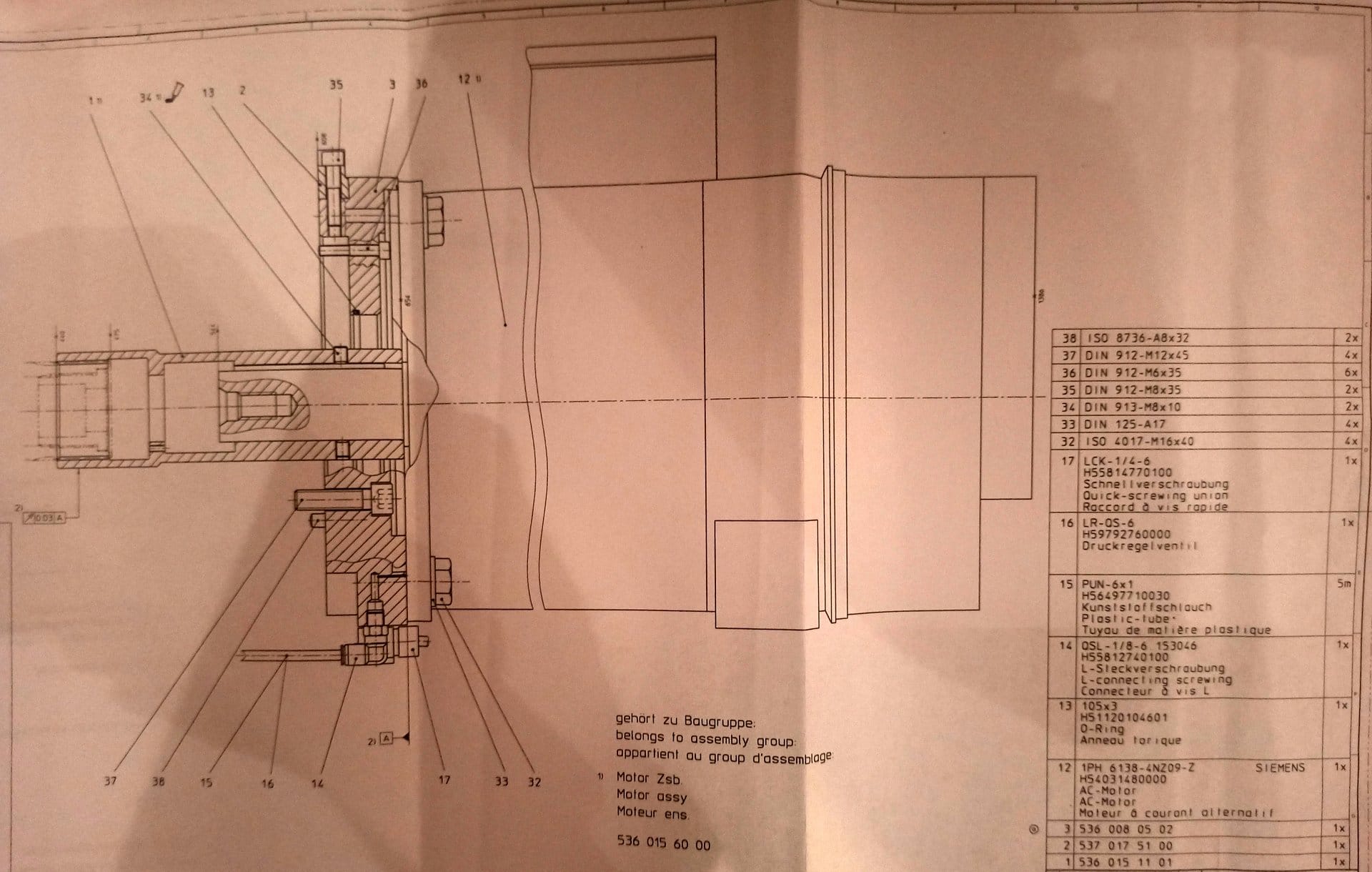

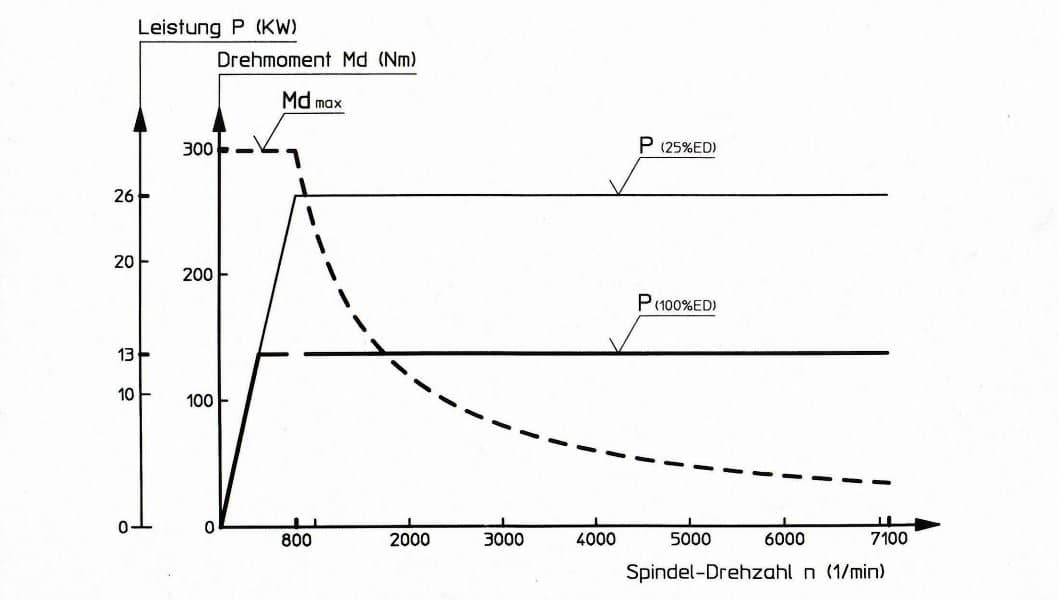

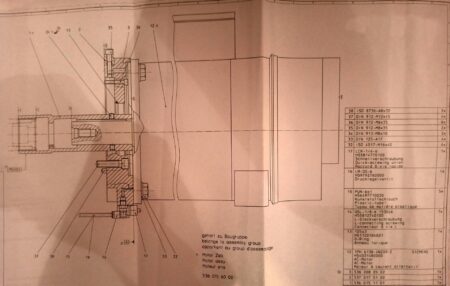

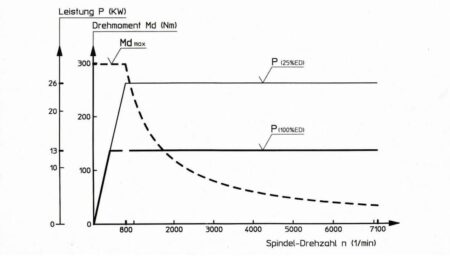

The machine’s construction is made of high quality steel, guarantees excellent heavy-duty stability, high reliability and a long service life. The machining centre spindle, rotating at a speed of 7200 rpm equipped with an SK 40 taper, ensures high precision machining and a significant reduction in production time.

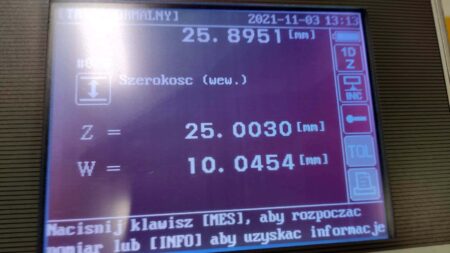

Full control over every aspect of machining and operation of the milling machine is provided by an installed SIEMENS SINUMERIK 810M CNC controller with a large and easy-to-use control panel. The CNC milling machine is equipped with original tool holders, a computer for programme transmission and a tool magazine able to hold 20 tools. Additional Bison toolholders and vices can be purchased at an additional cost. The total weight of the CNC milling machine is 5500 kg.

Technical data of the CHIRON FZ 18 S MAGNUM milling centre

- CNC controller: SIEMENS SINUMERIK 810M

- working table size (L x W): 1150 x 460 mm

- feed rates in the X/Y/Z axis: 750/400/425 mm

- maximum spindle speed: 7200 rpm

- spindle taper: SK 40

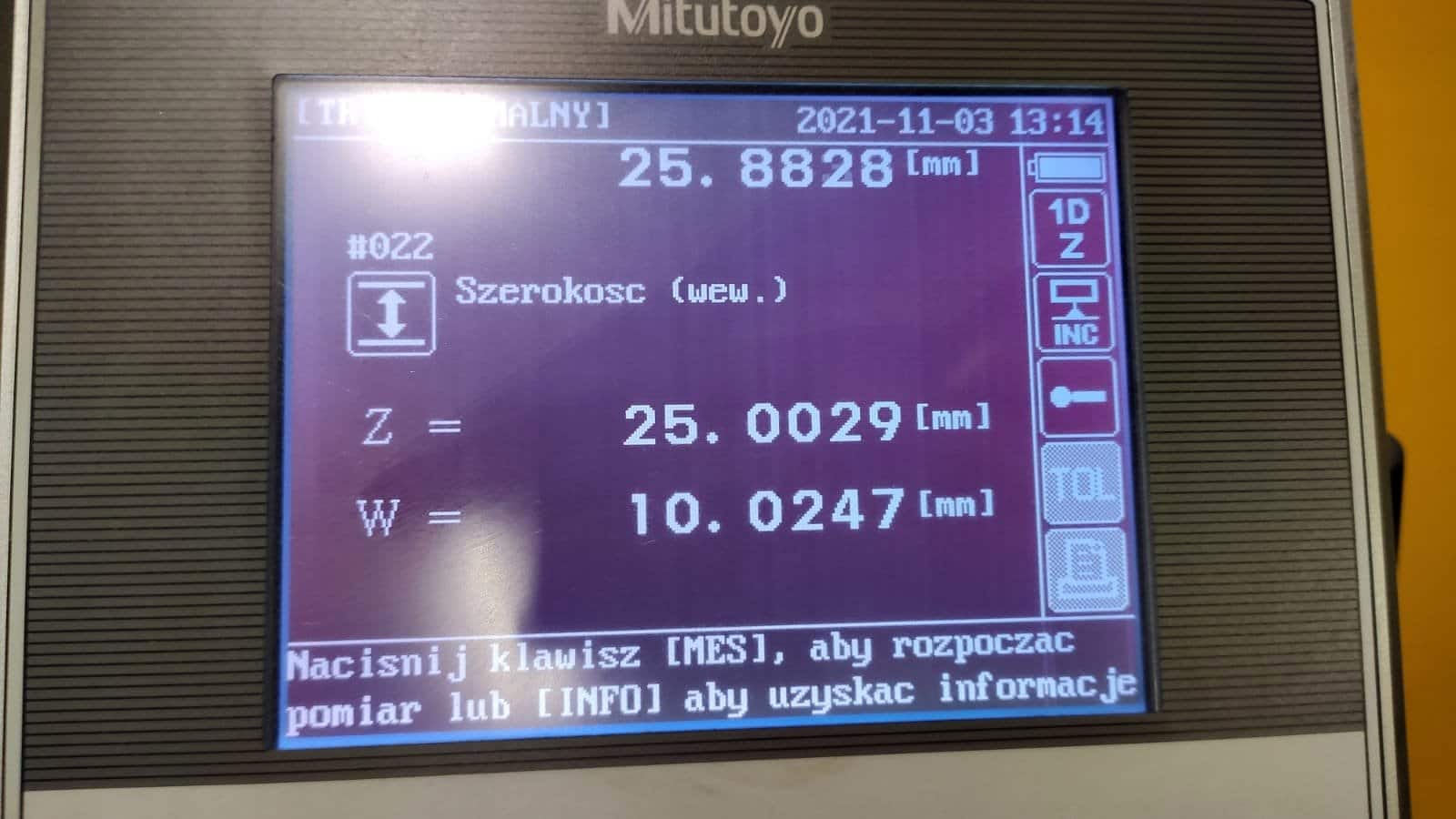

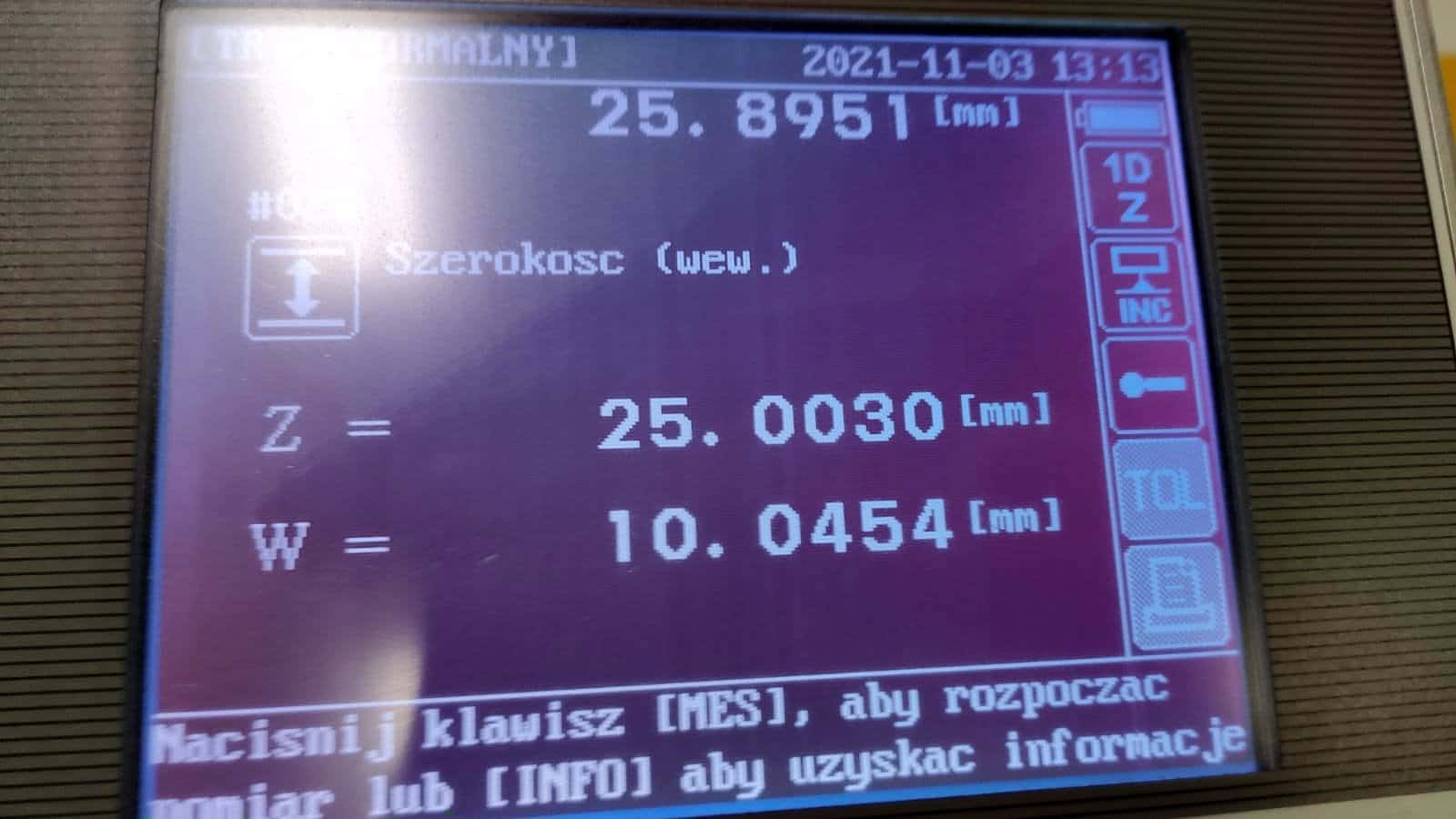

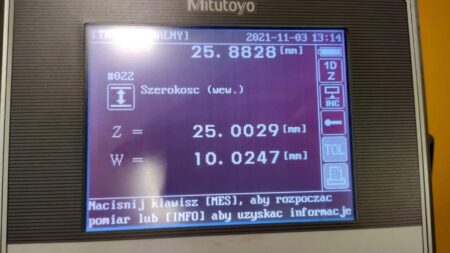

- machining accuracy (pitch): 0.01 mm

- machining accuracy (circle milling): 0.03 mm

- tool magazine capacity: 20 pcs.

- maximum tool diameter: 180 mm

- maximum tool length: 220 mm

- computer for programme transmission

- communication port RS233

- total energy requirement: 35 kVA

- power supply: 400 V

- dimensions of the FZ 18 S MAGNUM machine (L x W x H): 3143 x 1920 x 2673 mm

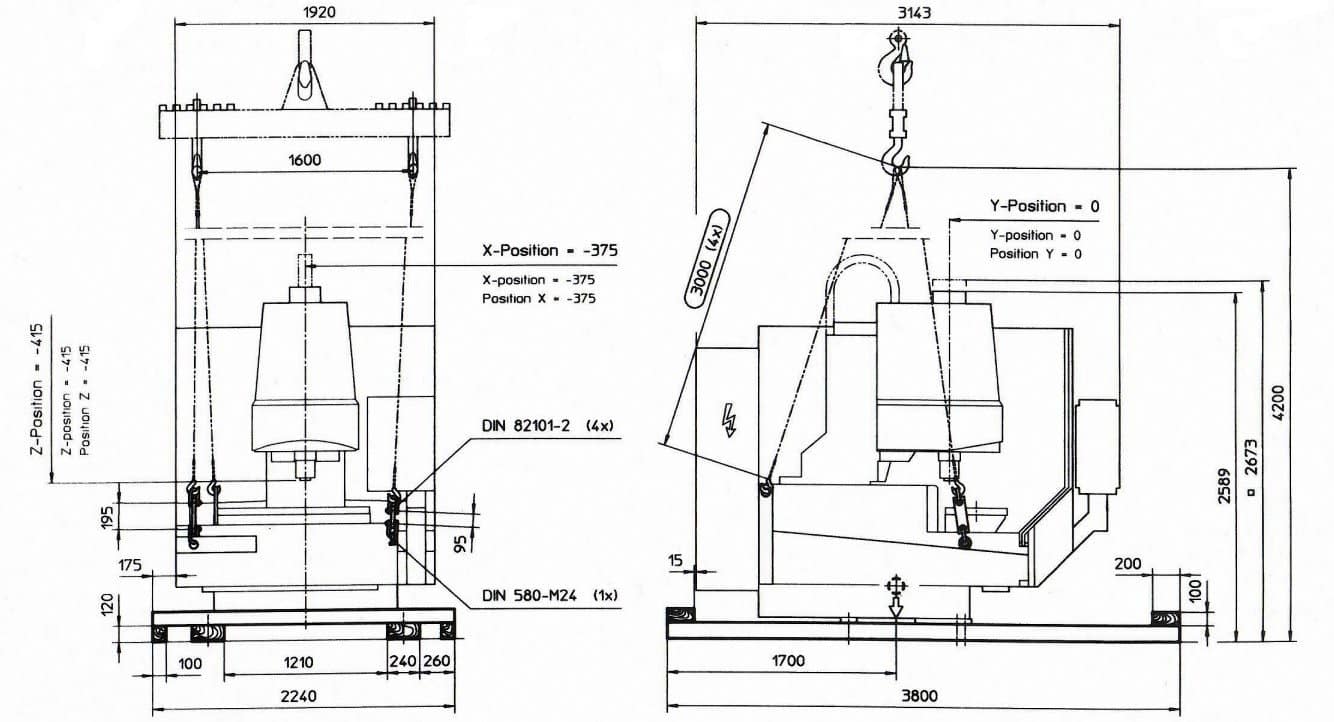

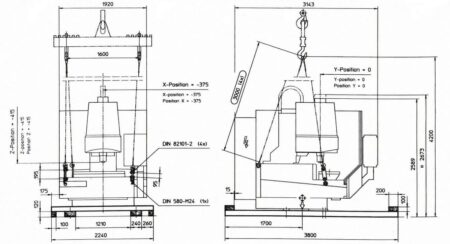

- total weight: 5500 kg

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe