CITIZEN CINCOM A20 VIPL CNC lathe built in 2006 ensures the highest precision and efficiency in the production process. During machining, the specially designed bed with its rigid structure and high thermal stability effectively reduces the heat impact, resulting in increased machine life and reliability. All of this, combined with a modular design with a reduced number of parts, makes the CINCOM A20 VIPL CNC lathe ideal for various types of production.

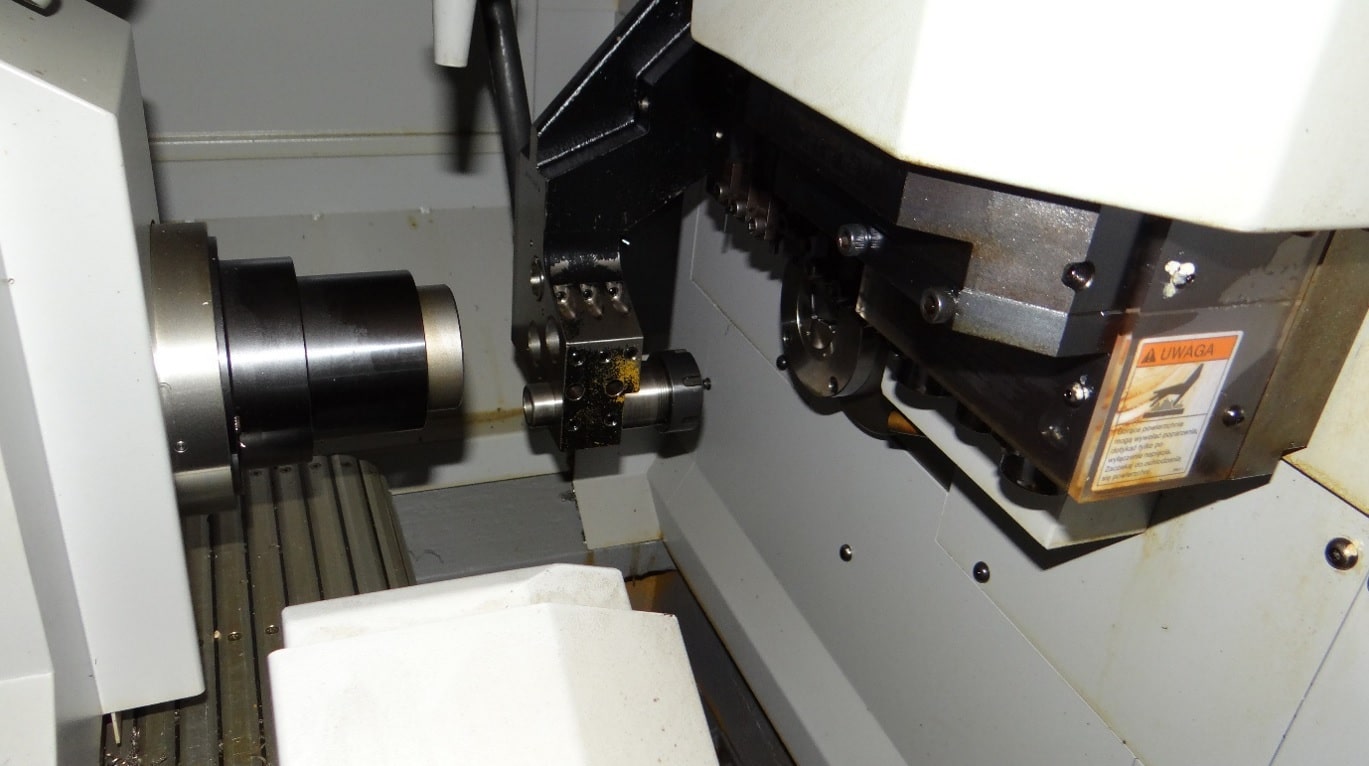

Workpieces with a maximum diameter of 20 mm and a length of 135 mm are machined in 7 axes by a powerful main spindle which is synchronised with an AC motor, forming an electrospindle. A bushing driven by a separate AC motor is also synchronised with the machine’s main spindle. The operator’s panel consists of an intuitive FANUC 32i CNC controller, a memory card slot and an electronic wheel located next to the monitor designed to check programmes at any speed.

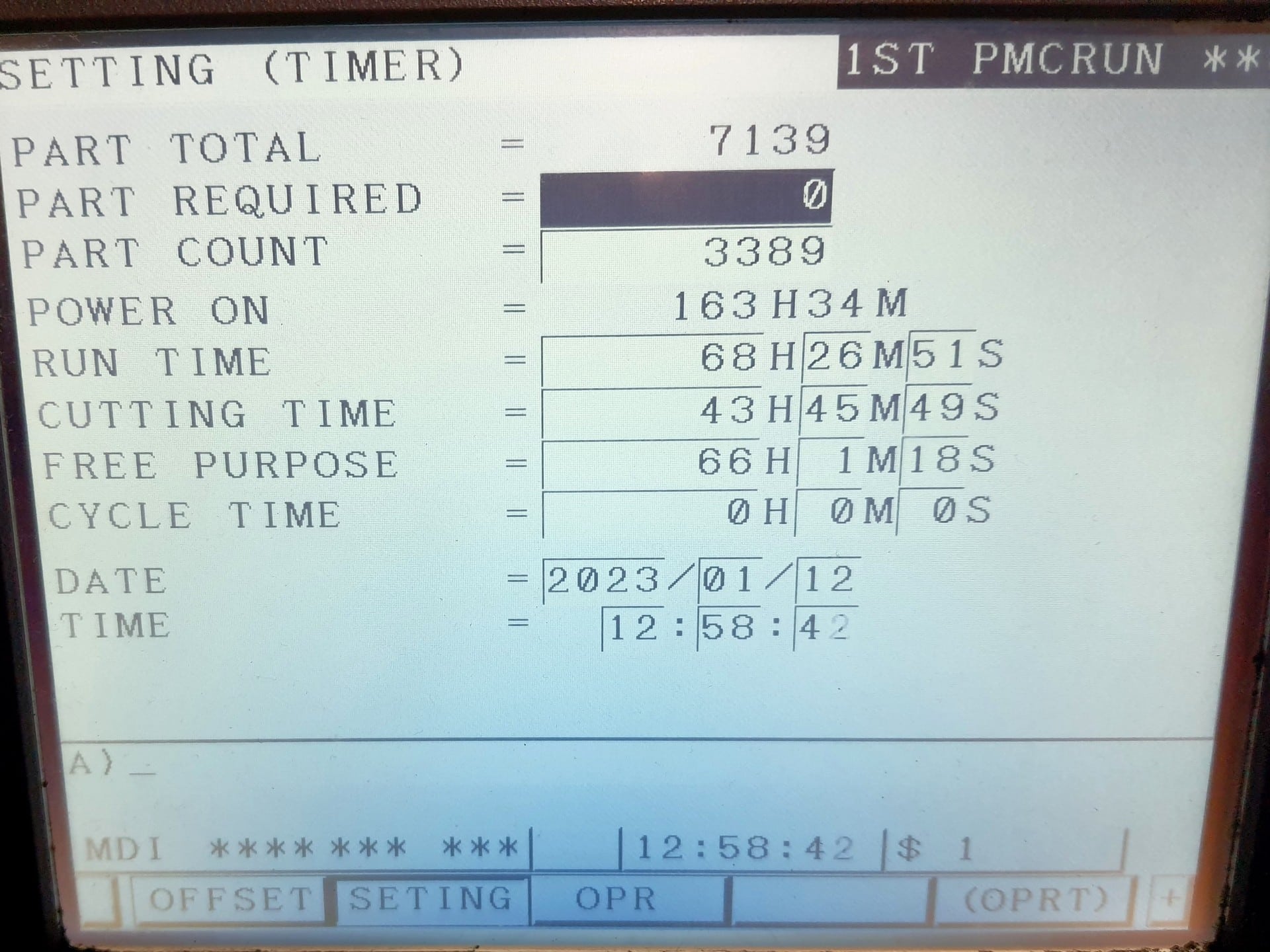

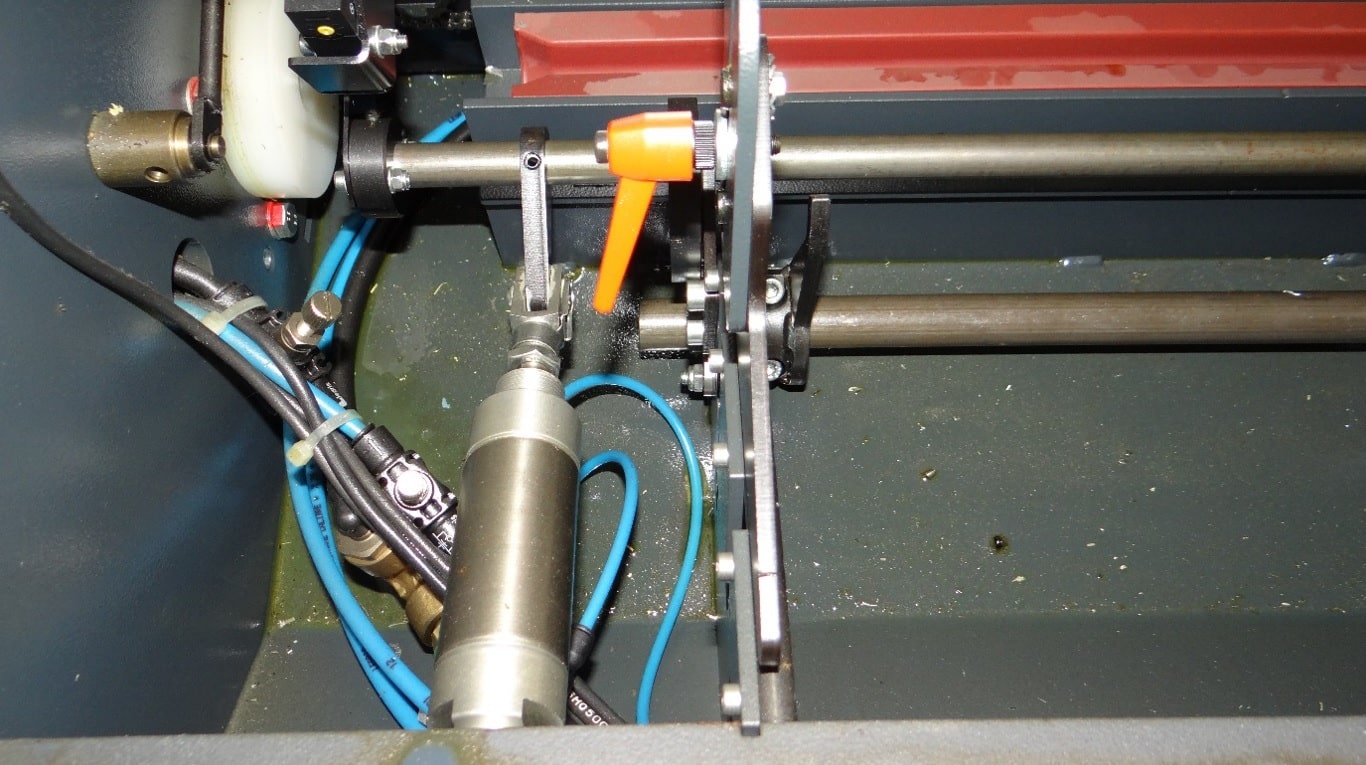

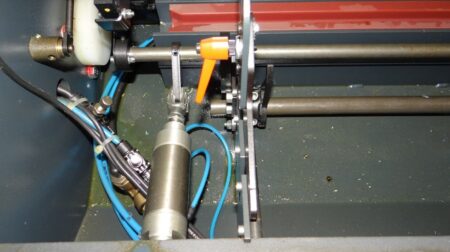

The lathe is offered with a wide range of equipment, including a sub-spindle, driven tools and an LNS Express 220 bar feeder. The machine was in operation for only 69 hours. The CITIZEN swiss type lathe weighs 2300 kg.

Specifications of CITIZEN CINCOM A20 VIPL CNC lathe

- working hours: 69 h

- number of axes: 7

- maximum turning diameter (main spindle): 20 mm

- maximum turning length: 165 mm

- maximum turning diameter (sub-spindle): 20 mm

- maximum capture length: 80 mm

- bar diameter range: 2-20 mm

- rapid traverse in X1 axis: 18 m/min

- rapid traverse in Y1, Z1, X2, Z2 axes: 32 m/min

- C-axis indexing (main spindle): every 0.001°

- C-axis indexing (sub-spindle spindle): every 0.001°

- maximum rotational speed (main spindle): 8000 rpm

- maximum rotational speed (sub-spindle spindle): 8000 rpm

- maximum drive power (main spindle): 3.7 kW

- maximum drive power (sub-spindle): 1.5 kW

- total number of tools in the head: 21

- number of driven tools: 4

- number of cutting tools: 5

- number of fixed tools for face drilling: 4

- number of fixed tools for back drilling: 8

- maximum rotational speed of driven tools: 8000 rpm

- driven tools drive power: 0.75 kW

- automatic bar change

- coolant tank capacity: 150 l

- dimensions (L x W x H): 2120 x 1240 x 1750 mm

- weight of machine: 2300 kg

Equipment of CINCOM A20 lathe

- CNC control: FANUC 32i

- bar feeder: LNS Express 220

- sub-spindle

- workpiece separator (device for collecting finished workpieces from the sub-spindle)

- workpiece ejection device with passage

- workpiece conveyor

- 5-position cutting tool support

- 2×4 position support for back machining

- 4-position support for front machining

- clamping bushing for main spindle: TF25

- guide bushing with drive

- rotary toolholder drive

- central lubrication

- sealing air flange

- workspace illumination

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe