CITIZEN CINCOM M32 CNC turning center built in 2011 in Japan provides precision drilling, threading and turning of workpieces with a maximum diameter of 32 mm. To improve the machining process, the machine uses two spindles (main spindle and back spindle) with high rotational speed and power. A specially designed bed with high thermal stability further reduces the impact of heat during machining, increasing the life and reliability of all components.

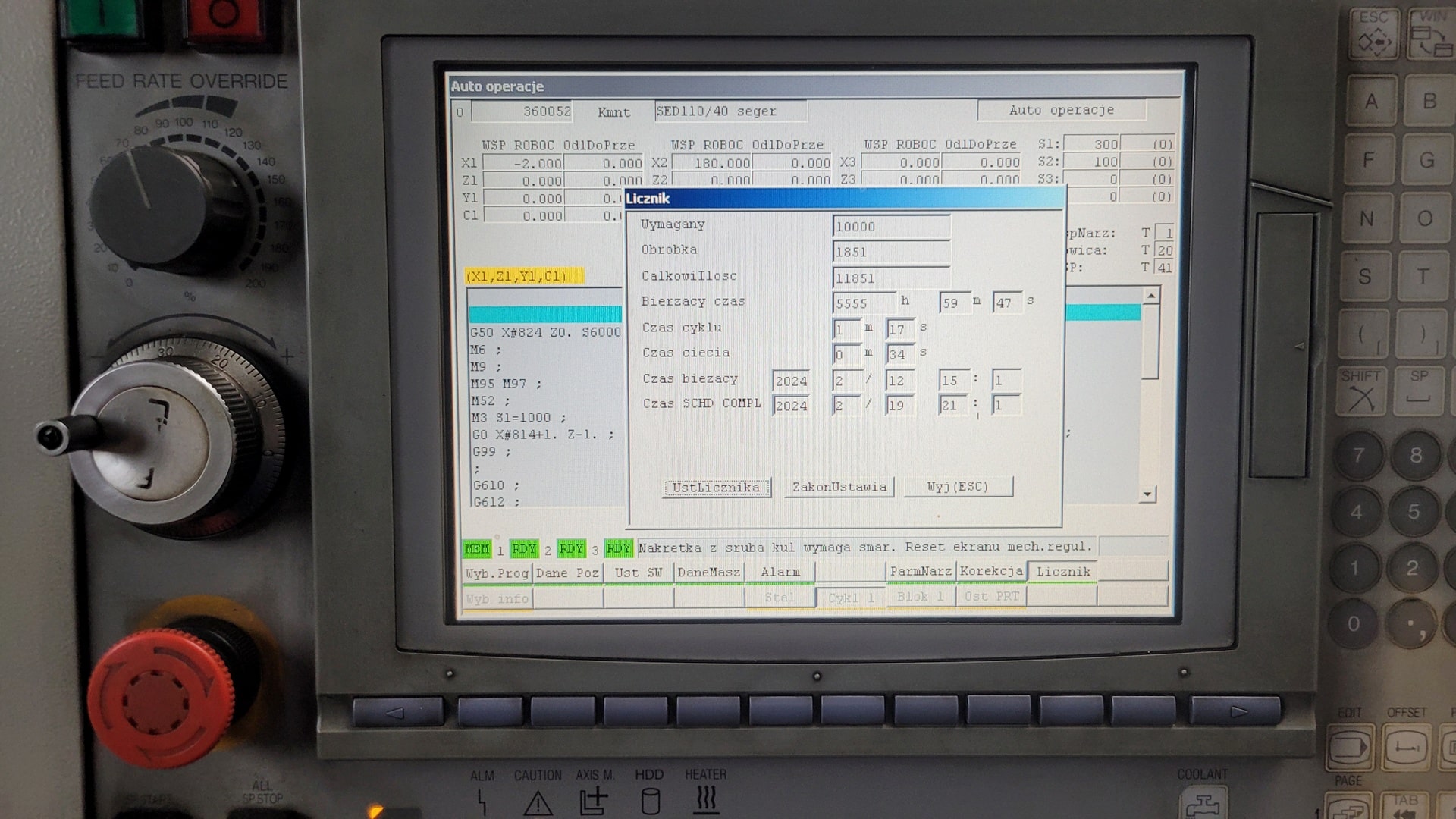

All machining parameters are programmed in the intuitive CINCOM SYSTEM M6D CNC control with many useful functions. Among the functions available, the controller allows, for example, self-diagnosis of the machine or program backup. High reliability, precision and extensive machining capabilities make the CITIZEN M32 III swiss-type lathe the ideal choice for even the most complex applications.

The offer also includes extensive additional equipment, including among others a bar feeder and oil mist extraction system. The CITIZEN CINCOM M32 CNC lathe weighs 3050 kg.

Technical specification of CITIZEN CINCOM M32 CNC lathe

General data

- number of axes: 7 (X1,X2,X3,Y1,Z1,Z2,Z3)

- feeds in the X1/X2/X3 axis: 108/135/238 mm

- feeds in the Y1 axis: 275 mm

- feeds in the Z1/Z2/Z3 axis: 325/202/410 mm

- rapid traverse in the X1,Y1,Z1 axis: 20 m/min

- rapid traverse in the X2/Z2 axis: 15.5/20 m/min

- rapid traverse in the X3,Z3 axis: 20 m/min

- least input increment in axis: 0.001 mm

- number of spindles: 2

- bar length: 2500 mm

- maximum number of tools: 22 + α, of which:

- maximum speed of rotary tools: 5000 rpm

- maximum tool dimensions:

– tool post 1: 16 x 16 x 130 mm

– tool post 2: 16 x 16 x 90 mm

– tool post 2 (sleeve): ⌀ 25.4 mm

– back tool post (sleeve): ⌀ 25.4 mm - maximum tool diameter in rotary toolholder of tool post 1 (drill and end mill): 10 mm

- maximum tool diameter in the rotary toolholder of tool post 2:

- centre height: 1100 mm

- main spindle motor power (15 min/continuous operation): 7.5/3.7 kW

- guide bushing drive motor power (10 min/continuous operation): 1.5/0.75 kW

- back spindle motor power (15 min/continuous operation): 3.7/1.5 kW

- tool post 1 servomotor power: 1 kW

- tool post 2 spindle power (10 min/continuous operation): 1.5/0.75 kW

- back tool post servomotor power: 0.75 kW

- coolant tank capacity: 140 l

- noise level: 77 dB(A)

- power supply: 3x 200 V; 50/60 Hz

- space requirement (L x W x H): 2805 x 1240 x 1790 mm

- weight of machine: 3050 kg

– tools in tool post 1: 5

– rotary tools in tool post 1: 4

– tools in tool post 2: 10 + α

– tools in back tool post: 3

– drill and end mill: 10 mm

– slitting cutter: 60 x 15.875 mm; 63 x 16 mm

– side cutter: 60 x 25.4 mm; 63 x 22 mm

– hobbing cutter: 32 x 10 mm

– polygon cutter: 80 x 15.875 mm

Main spindle

- maximum turning diameter: 32 mm

- maximum turning length: 320 mm

- maximum drilling diameter (front machining): 12 mm

- maximum threading diameter (front machining): M8 (tap), M6 (die)

- maximum rotational speed: 8000 rpm

- minimum rotational speed: 200 rpm

- spindle speed change: stepless, S + 4-digit numerical value

- through hole diameter: 36 mm

- C axis indexing: 0,001°

- spindle indexing: 1°

Back spindle

- maximum drilling diameter (back machining): 10 mm

- maximum threading diameter (back machining): M8

- maximum back spindle chuck diameter: 32 mm

- maximum workpiece protrusion length from back spindle: 65 mm

- maximum workpiece length for the front side collection from the back spindle: 145 mm

- maximum rotational speed: 7000 rpm

- minimum rotational speed: 200 rpm

- spindle speed change: stepless, S + 4-digit numerical value

- C axis indexing: 0,001°

- spindle indexing: 1°

Equipment of the CITIZEN CNC automatic lathe

- CINCOM SYSTEM M6D CNC control with many useful functions, i.e. self-diagnosis, zero point return, backup possibility, 3D interference check etc.

- bar feeder: FMB turbo 3-36

- back spindle

- 3 tool stations

- oil mist extraction: HE Filtration CleanMist

- main spindle collet chuck: MC081-M

- guide bushing: FG531-M

- rego type chuck: ER11/AR11 ER16/AR16

- back spindle collet chuck: FC081-M-K

- RS232 interface

- FDD interface

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe