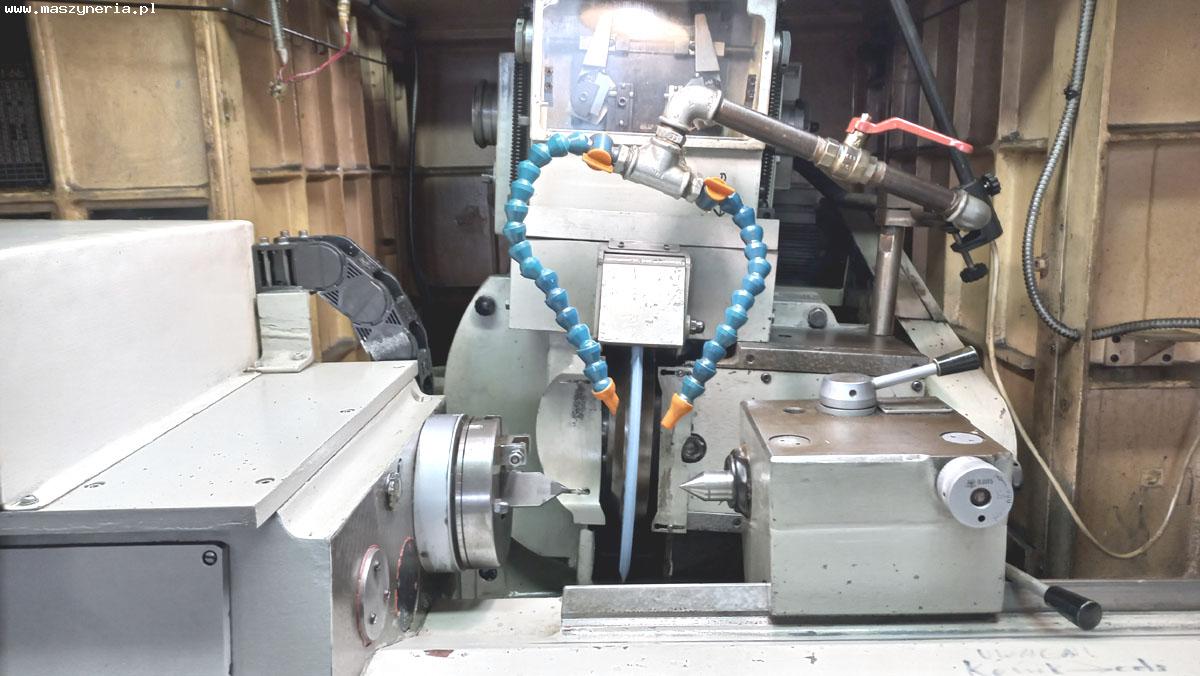

CNC thread and worm grinding machine 5K822B was manufactured in 1990 in the USSR. A major overhaul of the machine was carried out in 2018.

The thread grinding machine 5К822В with a wide range of machining capabilities enables a number of complex operations, i.e. grinding of threads and worms, cutting of any type of external and internal threads or milling of keyways. The workpiece is machined using the front and back spindles with mounted grinding wheels of a maximum diameter of 400 mm. In order to achieve the best results, the grinding wheel spindle is mounted on precision hydrodynamic bearings and runs on rolling guides. It is driven by a reliable DC motor with stepless speed adjustment. All this is complemented by the state-of-the-art PRONUM 600 numerical control with its intuitive interface and machining simulation function. All of this makes the 5K822V worm grinding machine an excellent choice for workshops and tool shops. The total weight of the machine is 4500 kg.

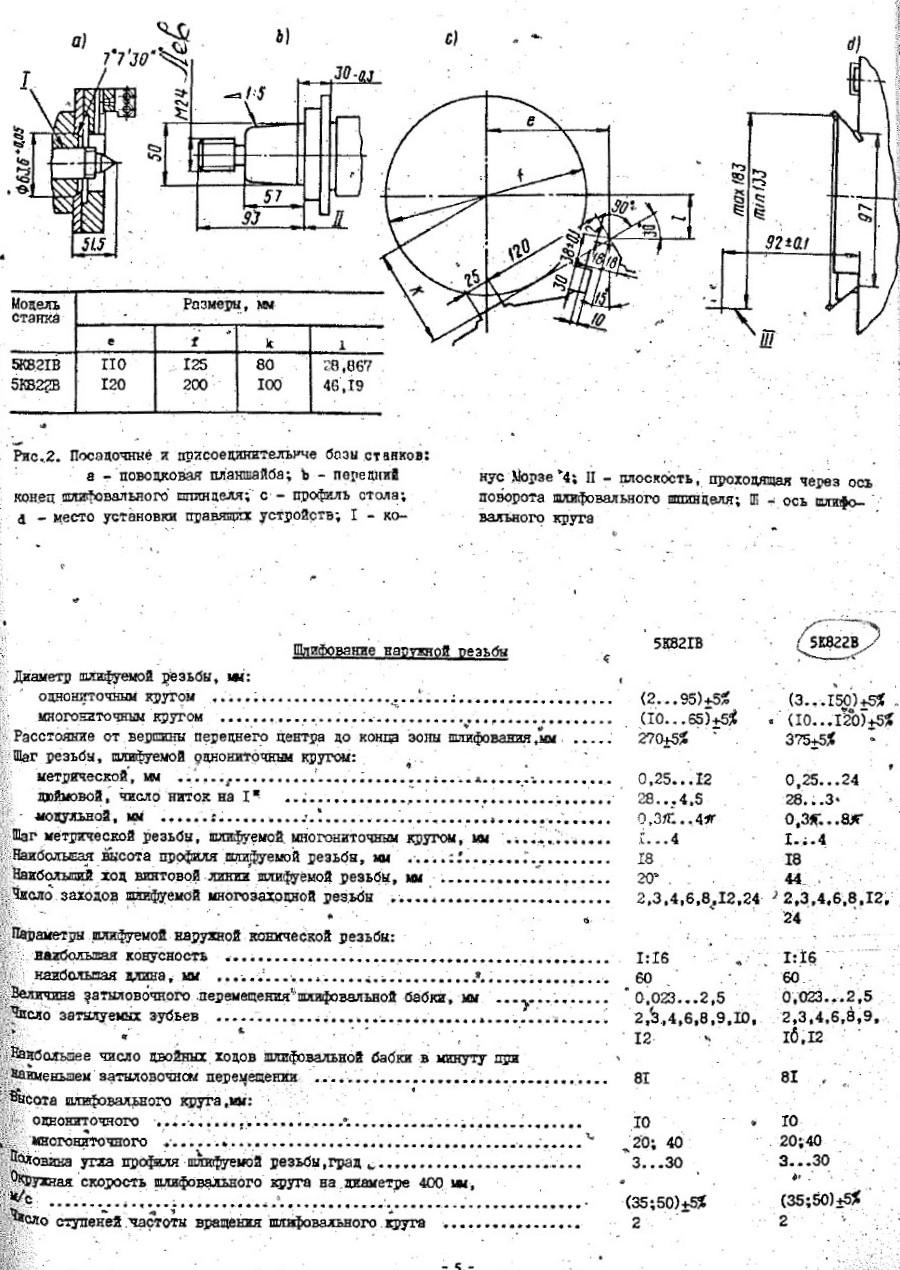

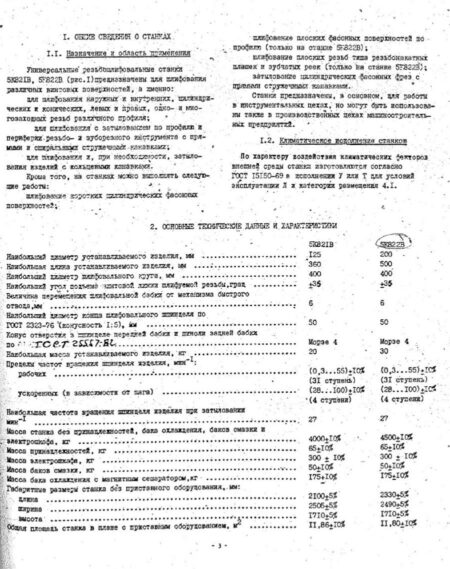

Technical specifications of the CNC grinding machine 5K822B

- CNC control: PRONUM 600

- maximum workpiece diameter: 200 mm

- maximum workpiece length: 500 mm

- maximum workpiece weight: 30 kg

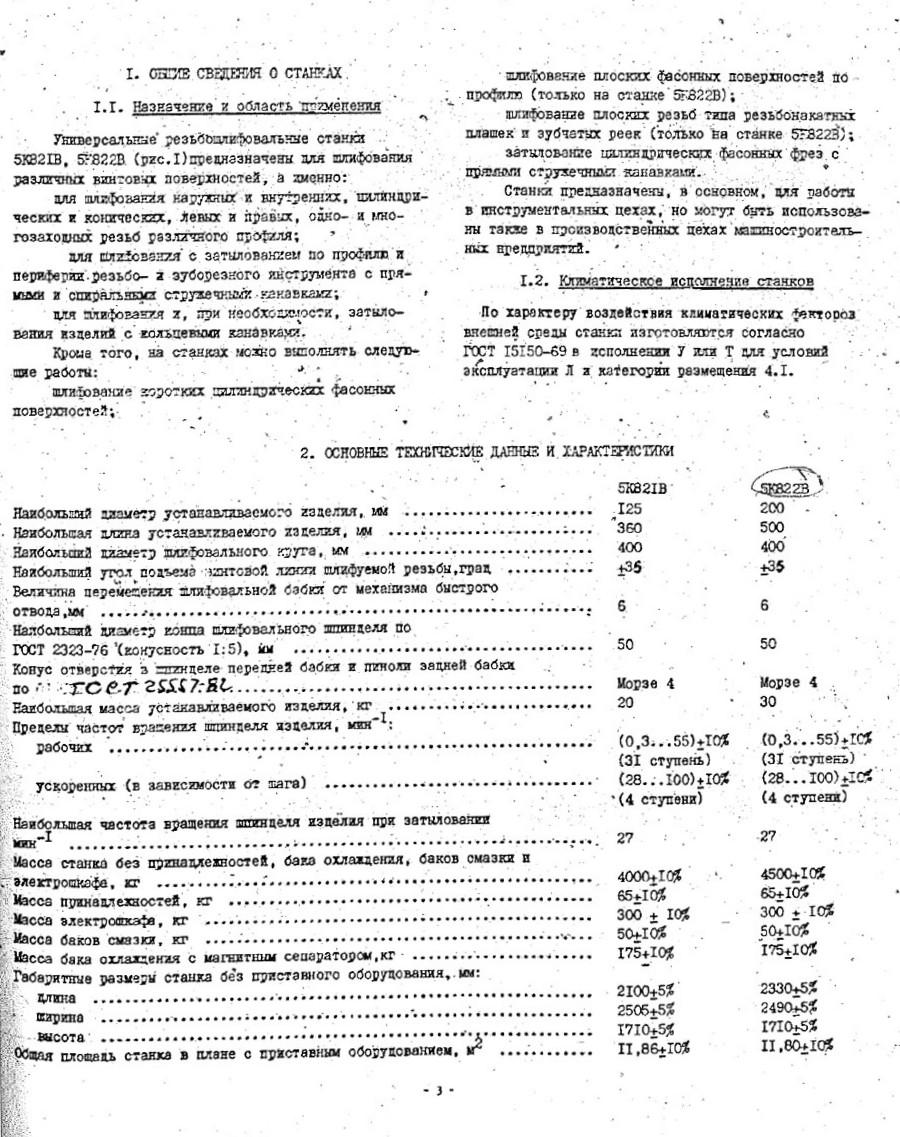

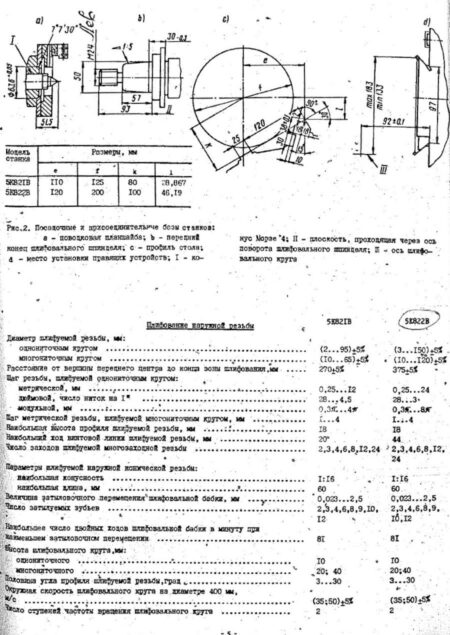

- metric thread stroke: 0.25-24 mm

- inch thread stroke: 28-3 TPI

- modular thread stroke: 0.3-8 mm

- number of thread turns: 2,3,4,6,8,12,24

- number of teeth: 2,3,4,6,8,9,10,12

- workpiece spindle speed: 0,3-55 rpm

- accelerated workpiece spindle speed: 28-100 rpm

- peripheral grinding wheel speed: 35 m/s

- maximum grinding wheel diameter: 400 mm

- grinding wheel spindle tip diameter: 50 mm

- grinding wheel spindle taper: Morse 4

- DTR – Technical and Operating Documentation

- dimensions (L x W x H): 2330 x 2490 x 1710 mm

- weight of the 5K822B machine: 4500 kg

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe