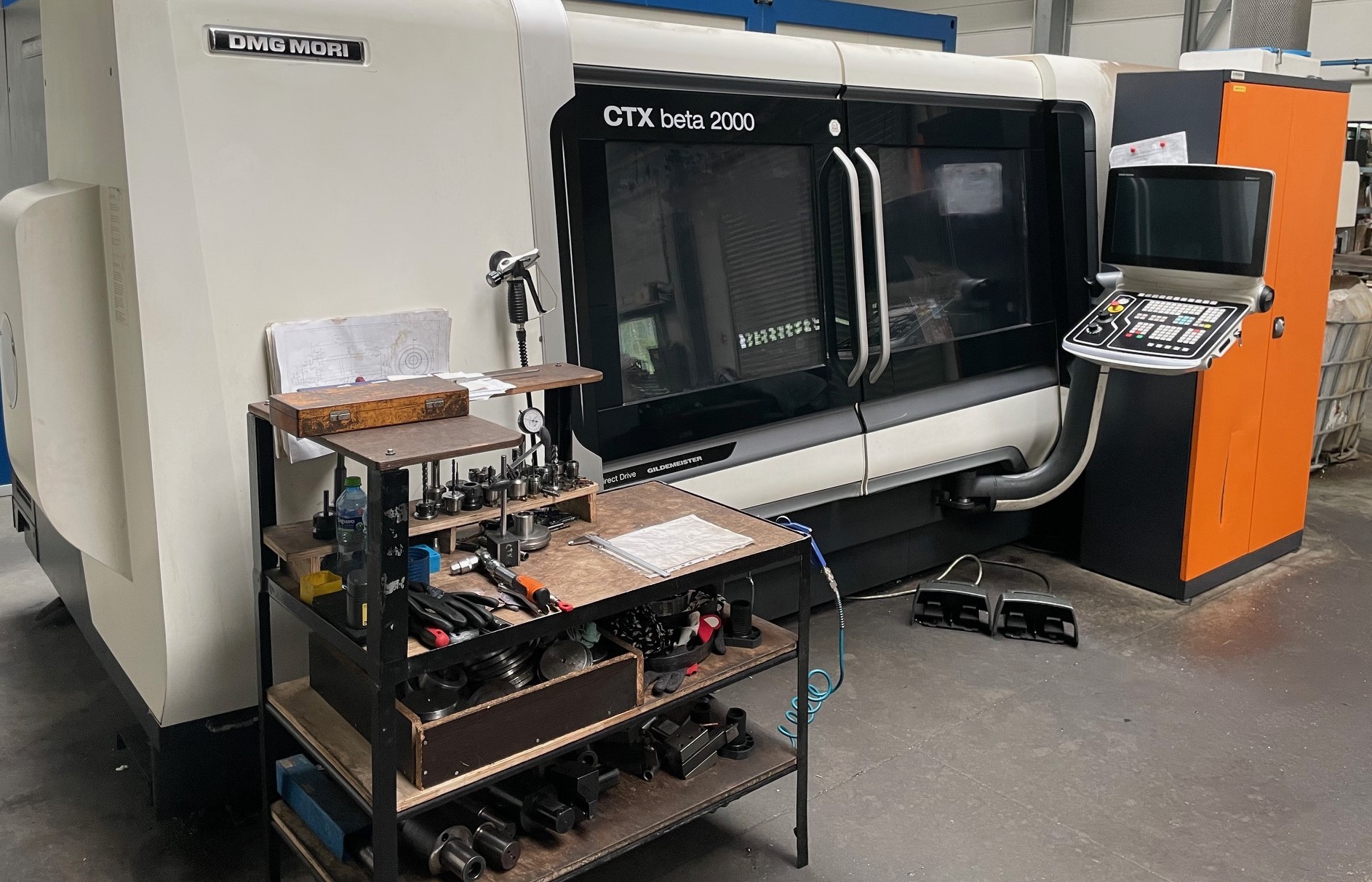

DMG MORI CTX Beta 2000 CNC turning center was built in 2020 in Italy by Graziano Tortona S.r.l.. This extremely efficient machine is offered together with an extensive range of equipment, which significantly expands the machining capabilities and guarantees the achievement of high repeatability of the manufactured parts. Thanks to additional function packages, it is possible to perform, e.g. precise gear milling or polygon turning.

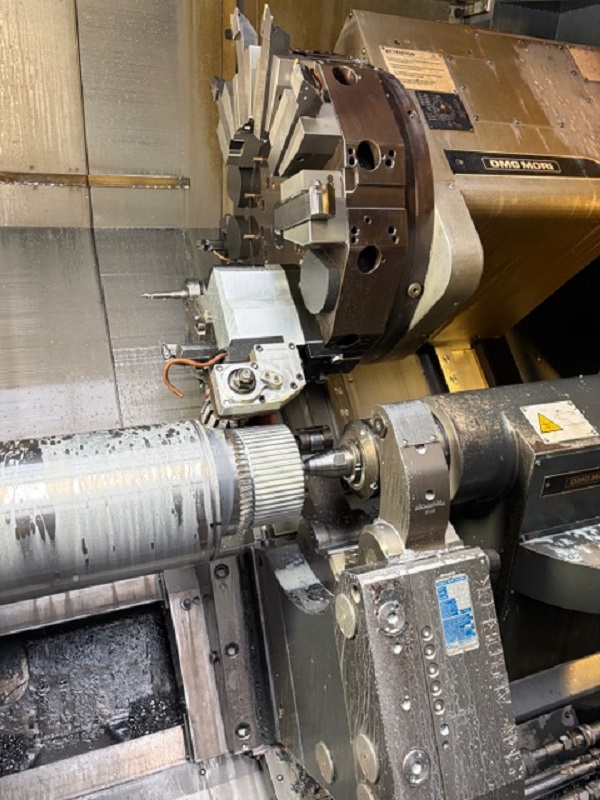

All machining processes are performed inside a large working area by means of a reliable spindle and cutting tools taken from a 12-position turret. The tailstock coupled to the Z-axis moves collision-free on separate sliding guides, mounted on a bed of high thermal stability. This bed is excellent at reducing the influence of heat, while increasing the life of all components and tools. Over its service life, the machine has worked for a total of 6219 hours. The CTX Beta 2000 CNC lathe weighs 11000 kg.

Technical specifications of the DMG MORI CTX Beta 2000 lathe

General data

- swing over bed: 800 mm

- maximum turning diameter: 600 mm

- maximum bar diameter: 102 mm

- maximum turning length: 2000 mm

- feed in the X/Y/Z axis: 415/75/2025 mm

- rapid traverse in the X/Y/Z axis: 30/22.5/33 m/min

- feed thrust in the X/Y/Z axis: 9/9/13 kN

- resolution of the X,Y,Z axis: 0.001 mm

- tailstock extension: 2025 mm

- tailstock quill extension: 150 mm

- tailstock quill diameter: 120 mm

- tailstock sleeve taper: MT5

- maximum tailstock thrust: 1800 daN

- bed inclination angle: 45°

- operating hours: 6219 h

- minimum compressed air pressure: 6 bar

- coolant tank capacity: approx. 250 l

- coolant pump output: 23 l/min

- hydraulic unit tank capacity: approx. 40 l

- maximum hydraulic unit pressure: 90 bar

- ambient temperature: +15°C/+35°C

- relative humidity: 75%

- noise level: 75 dB(A)

- power supply: 400 V; 50/60 Hz

- dimensions of machine without chip conveyor (L x W x H): approx. 5564 x 3150 x 2135 mm

- weight of the DMG MORI CTX Beta 2000 machine: 11000 kg

Main spindle

- maximum rotational speed: 3600 rpm

- bore diameter: 121 mm

- spindle nose: 220 h5 mm

- inner diameter of front bearing: 160 mm

- hydraulic brake

- C axis

- C axis rotational speed: 0-200 rpm

- C axis torque (40% ED): 770 Nm

- C axis accuracy: 0.001 mm

Tool head

- number of positions: 12 + 6 for blocktools

- maximum speed of driven tools: 4000 rpm

- tool holder: VDI 50

- 30° indexing time: 0.4 s

- drive power (40% ED): 12.5 kW

- torque: 70 Nm

Equipment of the DMG MORI metal lathe

- SIEMENS SINUMERIK 840D sl Operate CNC control with CELOS unified user interface

- additional function ‘turning and milling off-axis’

- additional function ‘gear milling by hobbing’

- additional function ‘polygon turning for machining elliptical and polygonal shapes’

- additional package for machining shafts

- Y axis

- tool measuring probe: RENISHAW RP3

- direct measurement system in the X and Y axis

- 3-jaw mechanical lathe chuck with through hole

- spindle with 104 mm diameter through-hole clamping mechanism

- touch screen control panel: DMG MORI ERGOline

- IoTconnector (communication device for networking of machines via open protocols)

- DMG MORI Messenger V2 (application for monitoring machine status on smartphones, tablets and PCs)

- DMG MORI Service Agent (application for checking any required maintenance with a list of required spare parts and equipment)

- NETservice (remote technical support)

- SERVICEcamera (camera for live streaming via NETservice)

- VDI 50 toolholders

- toolholder for hobbing of gears, grooves, teeth etc.

- toolholder for mounting boring bars

- driven angle toolholder (1 pc)

- driven straight toolholder (2 pcs)

- chip conveyor

- chip flushing gun

- coolant pump 12 bar

- hydraulic unit with pump and filter system

- oil mist

- automatic central lubrication

- 4-colour indicator lamp

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe