ECKERT Opal WaterJet COMBO cutting machine was built in 2012 in Poland. The machine combines all the advantages of plasma and waterjet cutting technologies, guaranteeing fully automated machining of workpieces with both technologies and significant reduction of production costs compared to other machines of this type. The structure of the water cutting machine made of high quality closed steel profiles, achieves excellent dynamics and high stability during the cutting process.

The ECKERT Opal WaterJet COMBO 1500 x 3000 mm water cutting machine is equipped with a durable and corrosion-resistant working table with a length of 3000 mm and a width of 1500 mm. All running parts of the table have been protected from water with bellows covers. The equipment also includes a highly reliable VICTOR THERMAL DYNAMICS Ultra-Cut 100 plasma unit for ultra-fast cutting of workpieces with a maximum thickness of 200 mm and a ThyssenKrupp HPS 4022 high-pressure pump, guaranteeing high-precision machining of workpieces with a maximum thickness of 250 mm.

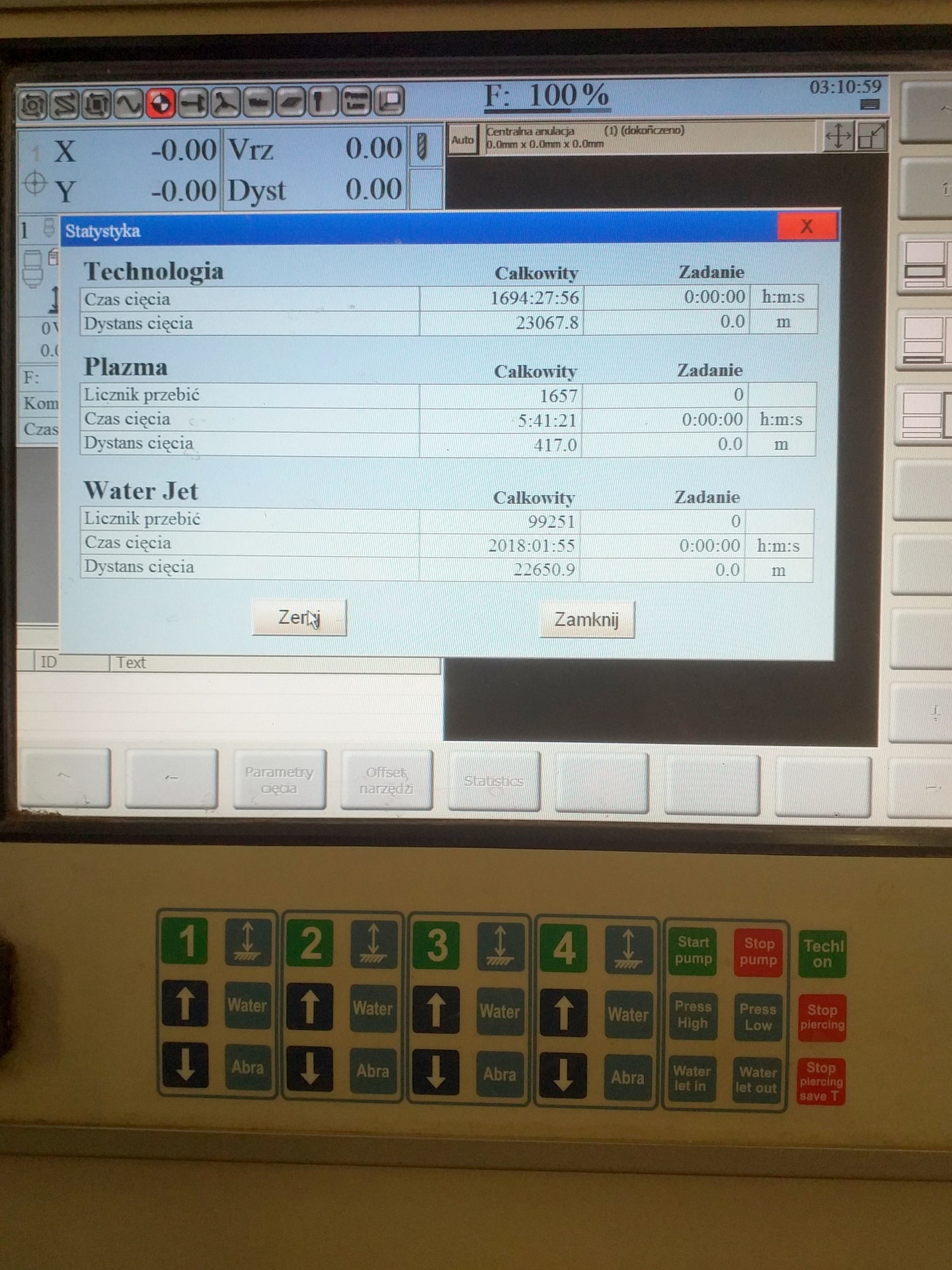

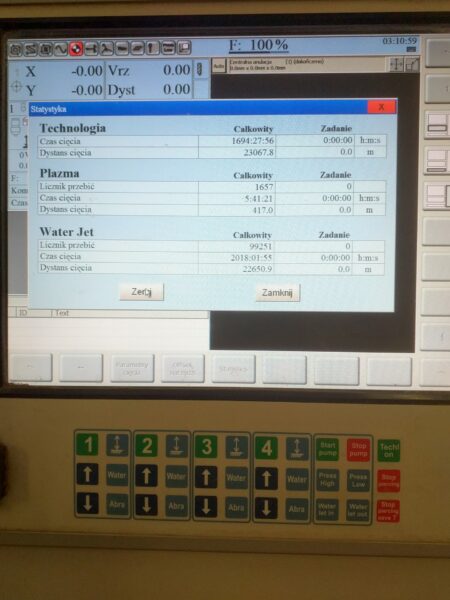

The modern and intuitive ECS 872 CNC control with high-end components ensures that all the capabilities of the WaterJet are utilised and trouble-free operation over the machine’s entire service life. The WaterJet ECKERT Opal COMBO is very versatile – it can operate in both large and small industrial plants.

Technical data of water cutting machine ECKERT Opal WaterJet COMBO

- work table surface (L x W): 3000 x 1500 mm

- maximum workpiece thickness (water jet): 250 mm

- maximum workpiece thickness (oxygen torch): 200 mm

- positioning accuracy: ± 0.025 mm

- travel speed: 25000 mm/min

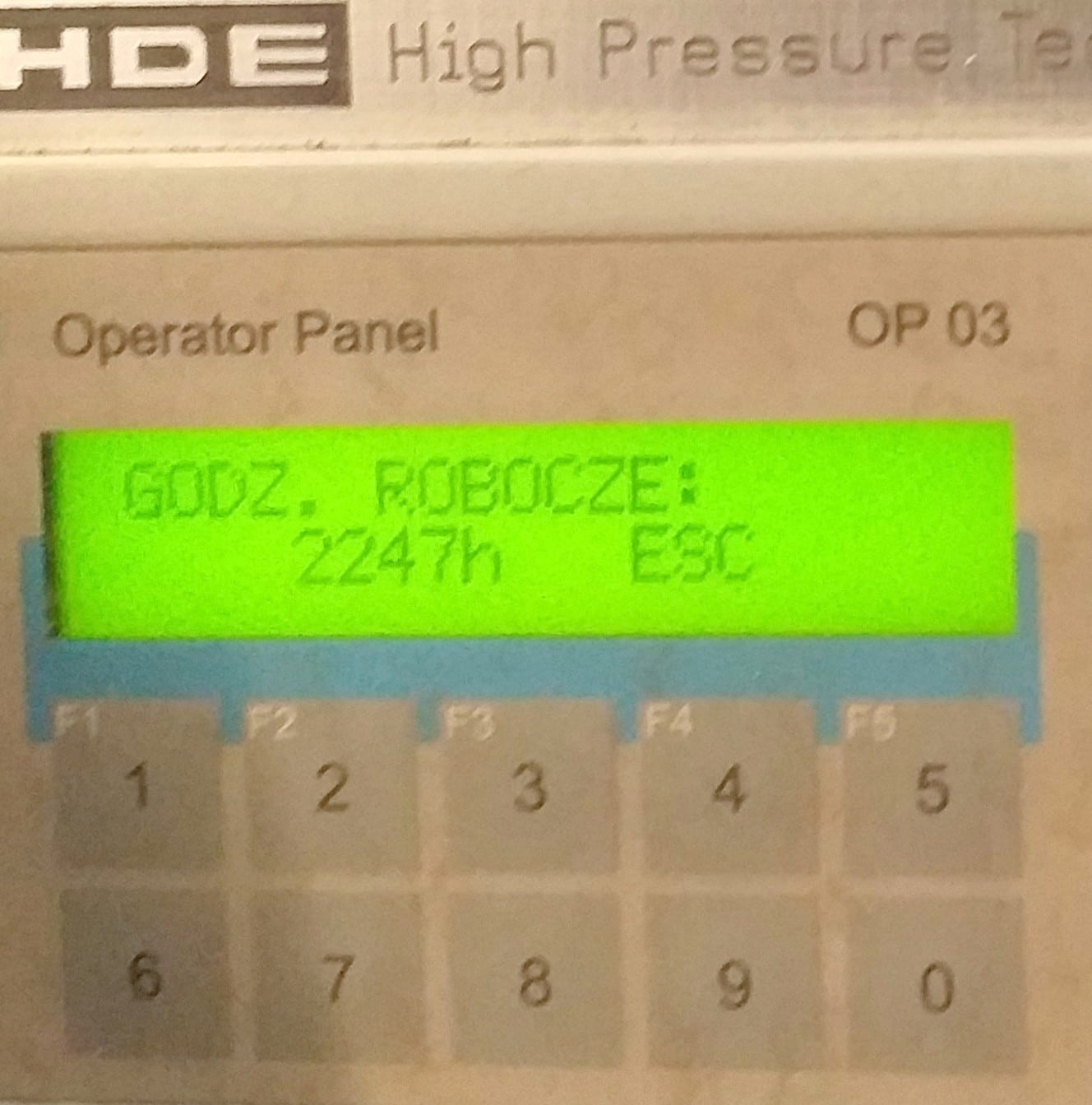

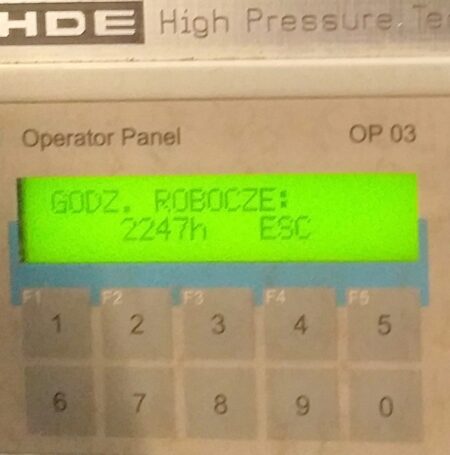

- working hours: 2247 h

- programming format: ESSI, NCP

- high-pressure pump capacity: 2.3 l/min

- high-pressure pump maximum pressure: 4000 bar

- high pressure pump power: 22 kW

- high-pressure pump weight: 1055 kg

Equipment of the water cutting machine

- CNC control: ECS 872

- high-pressure pump: ThyssenKrupp HPS 4022

- plasma source: VICTOR THERMAL DYNAMICS Ultra-Cut 100

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe