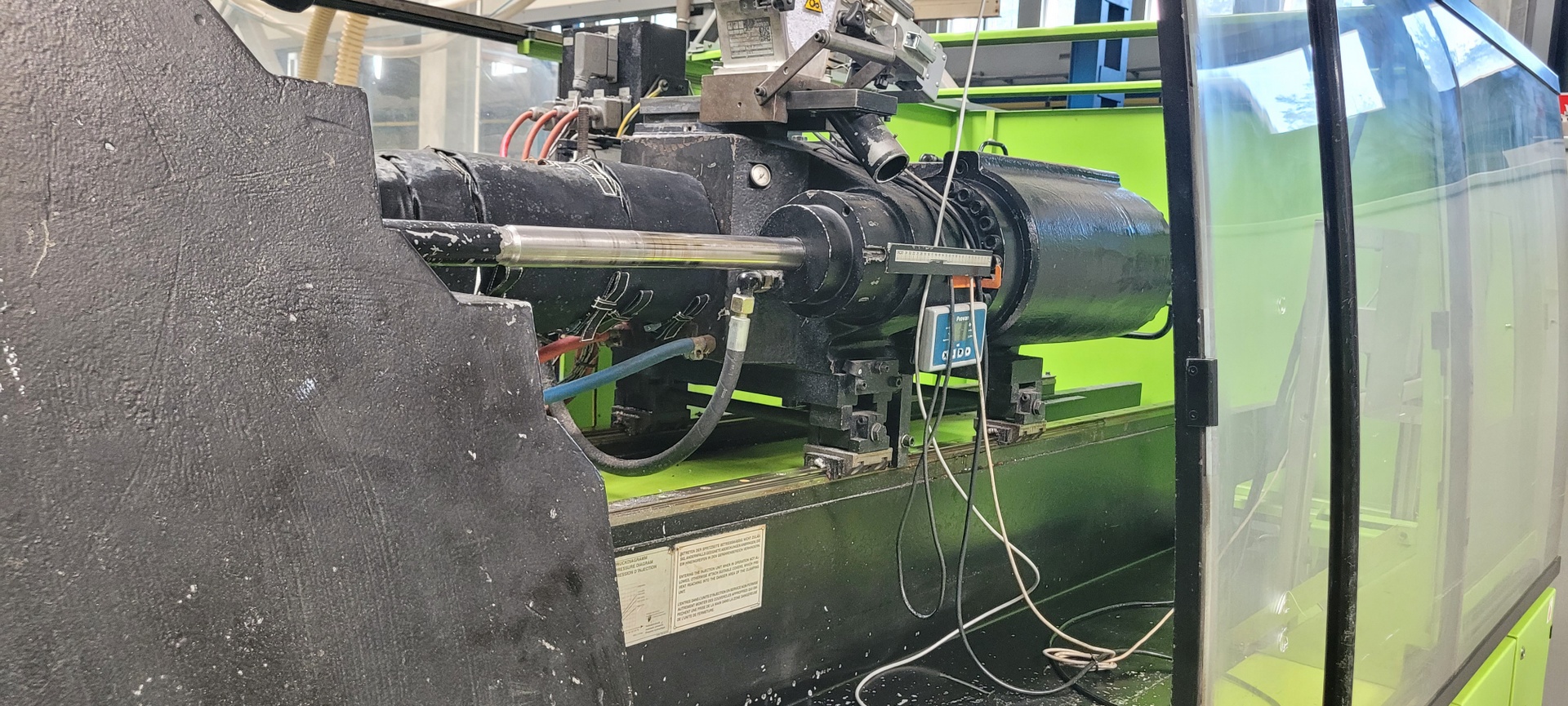

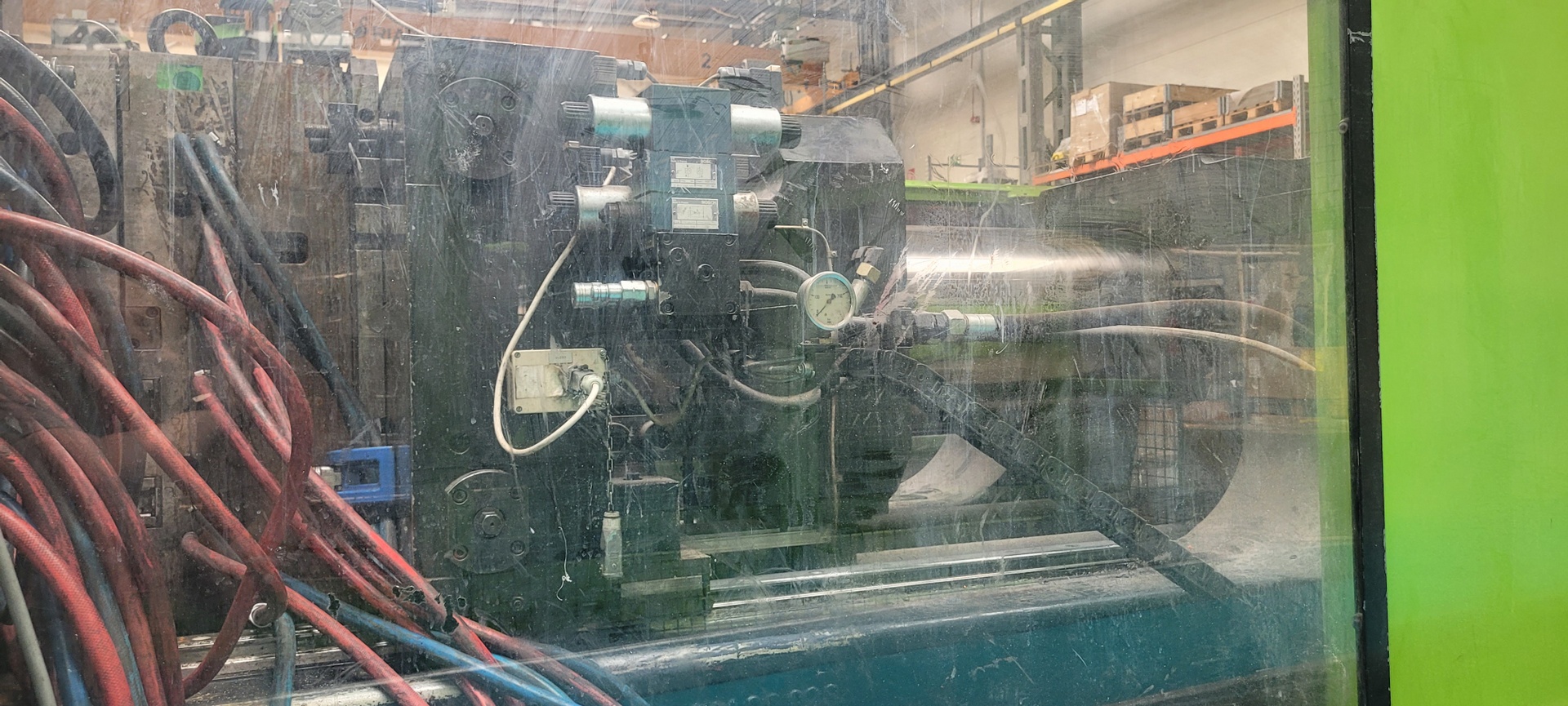

ENGEL ES 1350/350 HL injection moulding machine was built in 1995 in Austria by ENGEL AUSTRIA GmbH. The machine, which is designed for the economical production of plastic parts, is distinguished by the use of many components with excellent technical parameters. These parts are produced using the reliable injection moulding method, which involves feeding plasticised plastic into a mould and then clamping it with high press force. A precision mould clamping system, operating at a maximum force of 350 tonnes, guarantees high repeatability and quality of the manufactured parts. Once the production process is complete, the robot automatically transfers the finished products from the workspace to a conveyor belt. The ES 1350/350 HL injection moulding machine weighs 5000 kg.

Technical specifications of the ENGEL ES 1350/350 HL injection moulding machine

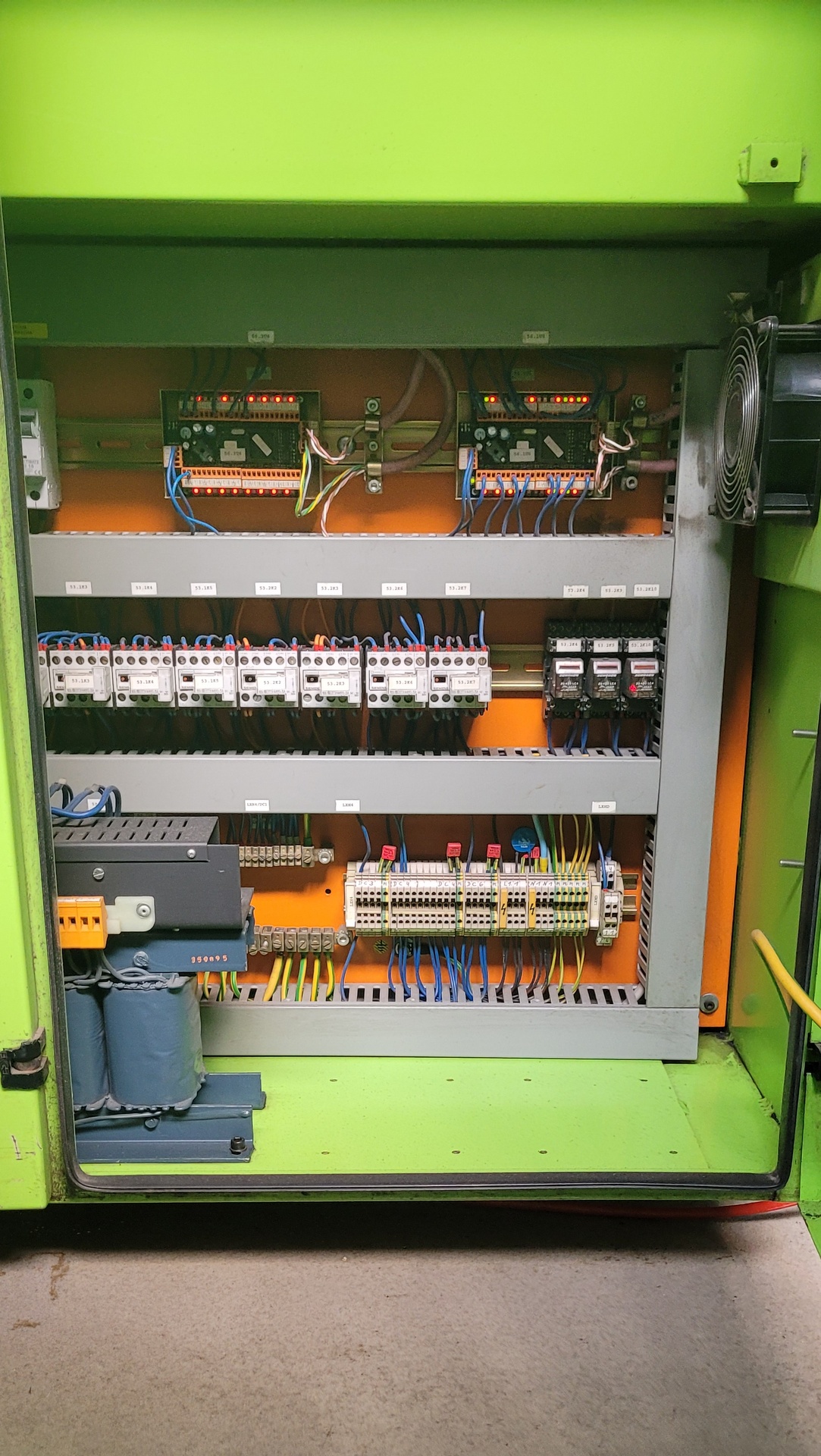

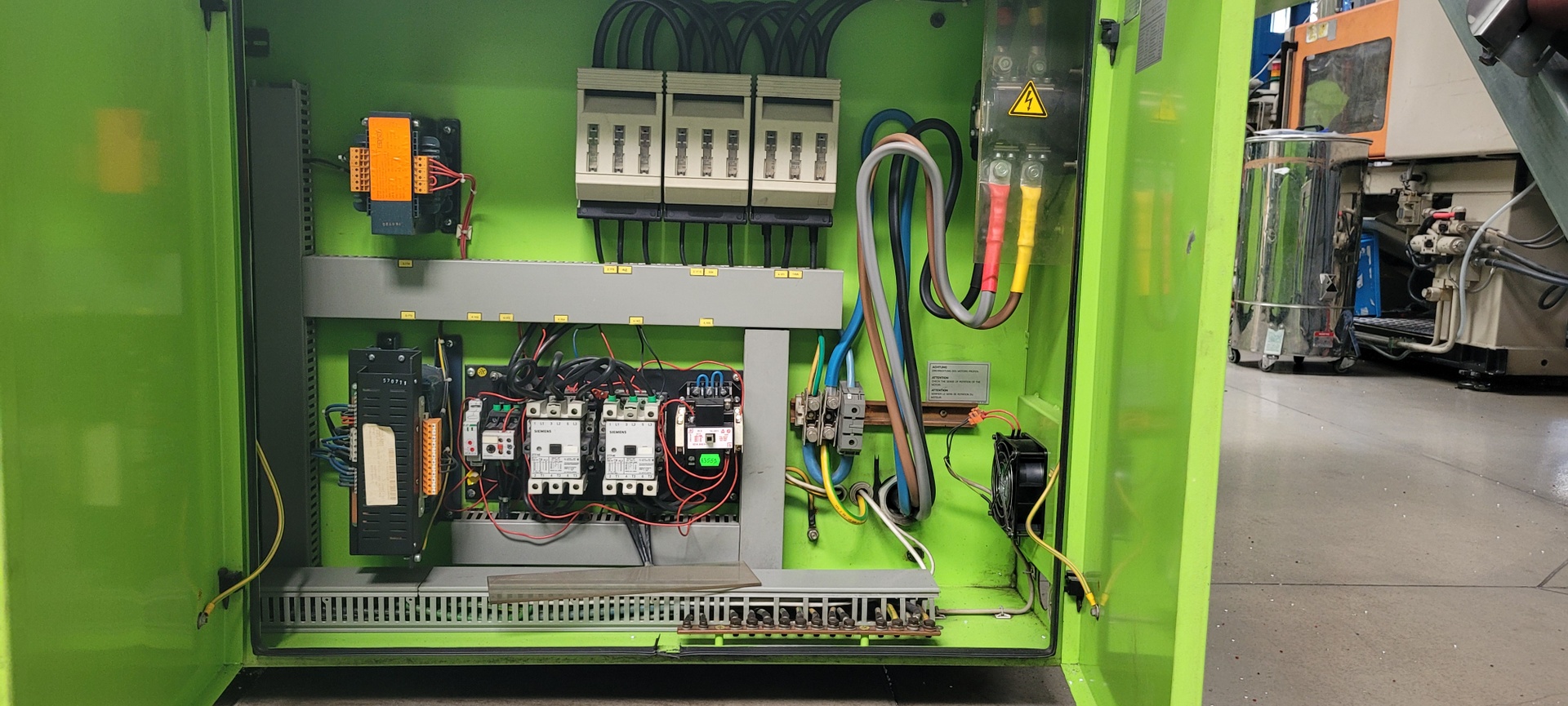

- CNC controller: ENGEL

- maximum mould clamping force: 350 t (3500 kN)

- screw diameter: 55 mm

- screw stroke: 260 mm

- maximum screw rotational speed: 285 rpm

- injection pressure: 1763 bar

- injection pressure (increased capacity): 2183 bar

- injection volume: 618 cm3

- injection weight: 556 g

- injection capacity: 339 g/s

- plasticisation capacity: 55 g/s

- clamping platen dimensions (standard): 1300 x 740 mm

- clamping platen dimensions (enlarged): 1300 x 1080 mm

- maximum distance between clamping platens: 1300 mm

- mould opening stroke: 950 mm

- ejector force: 82 kN

- ejector stroke: 250 mm

- injection nozzle clamping force: 110 kN

- injection nozzle clamping stroke: 500 mm

- robot: ENGEL ERC

- belt conveyor

- pump power: 45 kW

- number of heating zones: 5

- heating power: 19.8 kW

- oil tank capacity: 580 l

- additional oil tank capacity: 400 l

- weight of the ENGEL ES 1350/350 HL machine: 5000 kg

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe