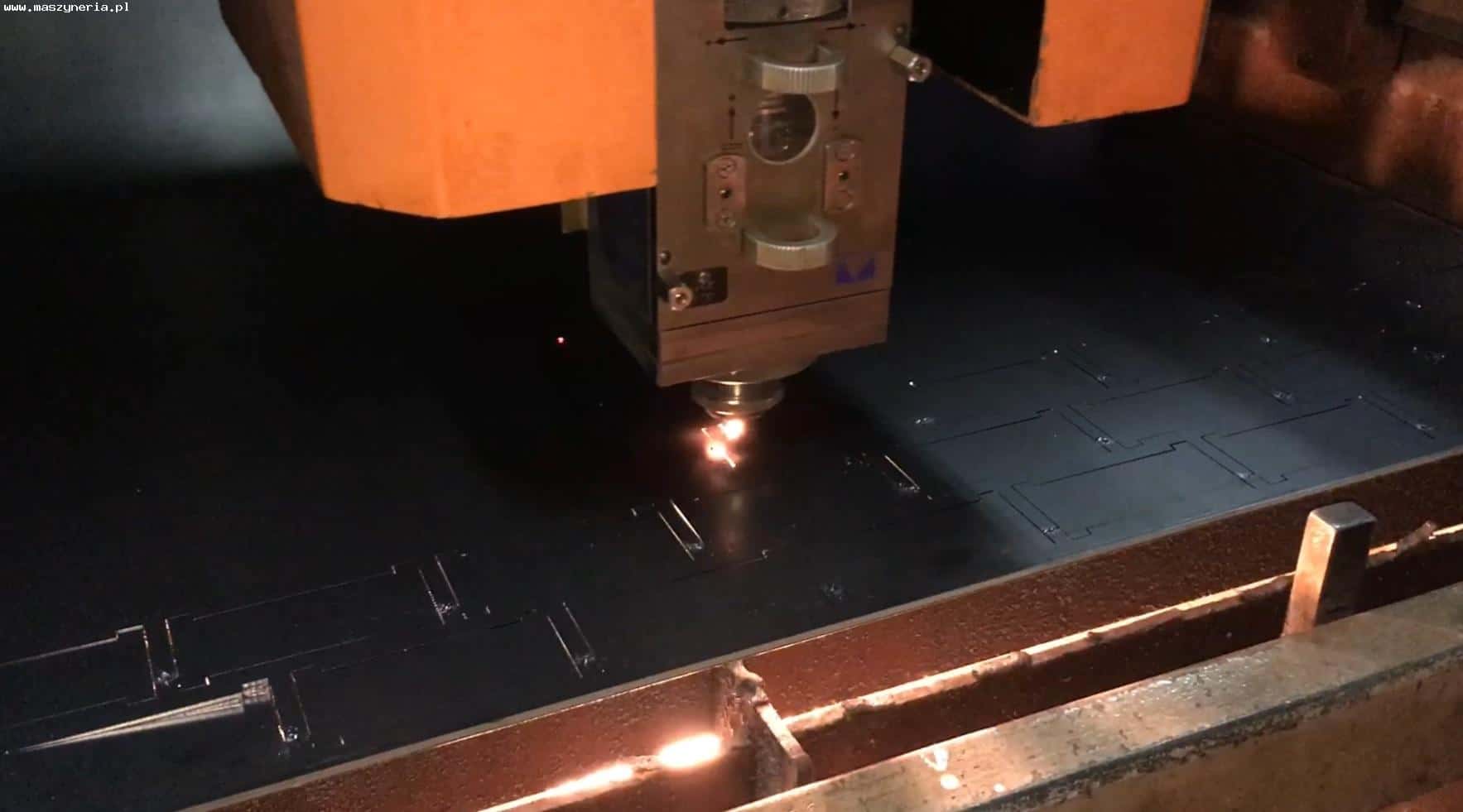

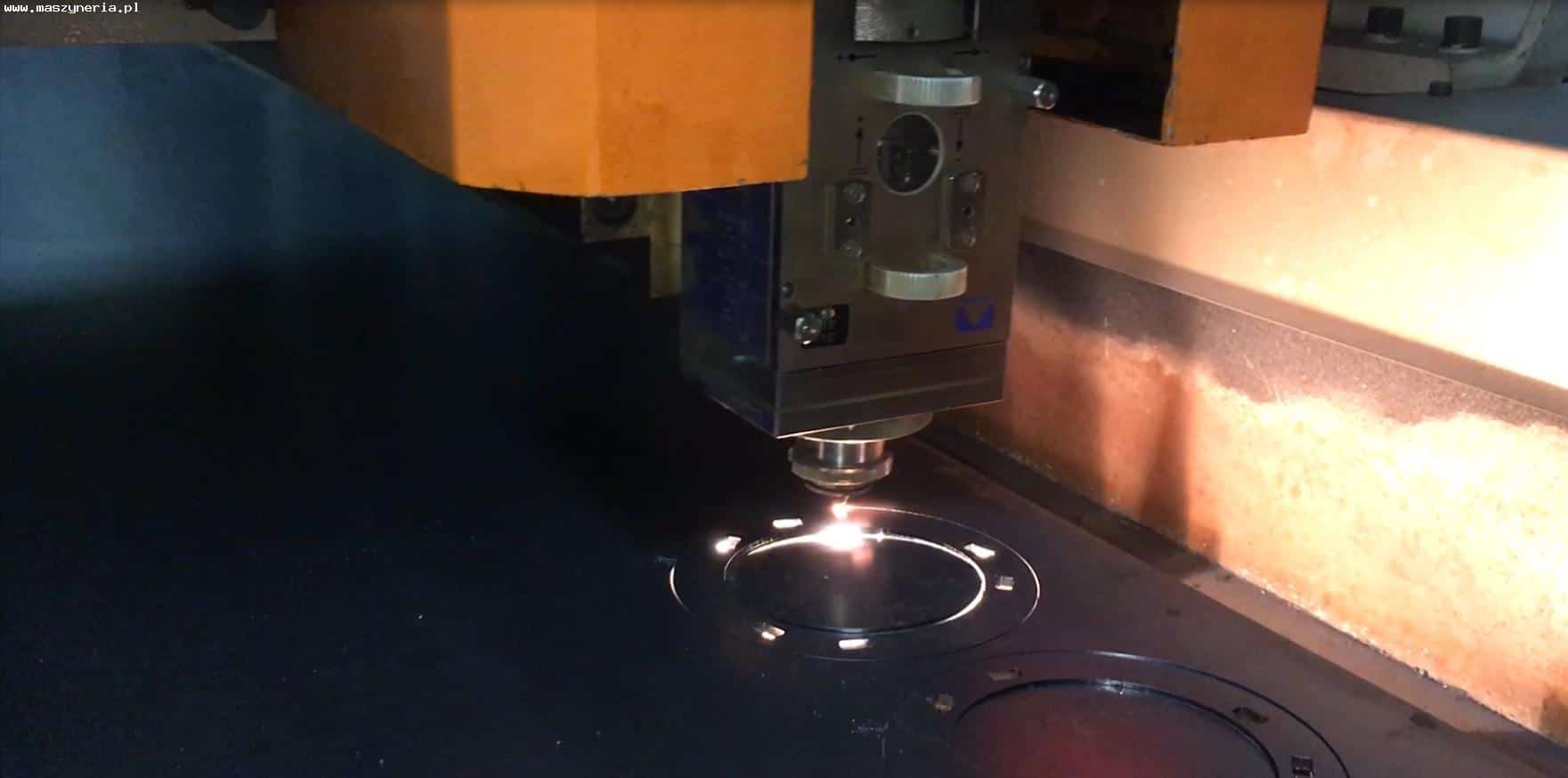

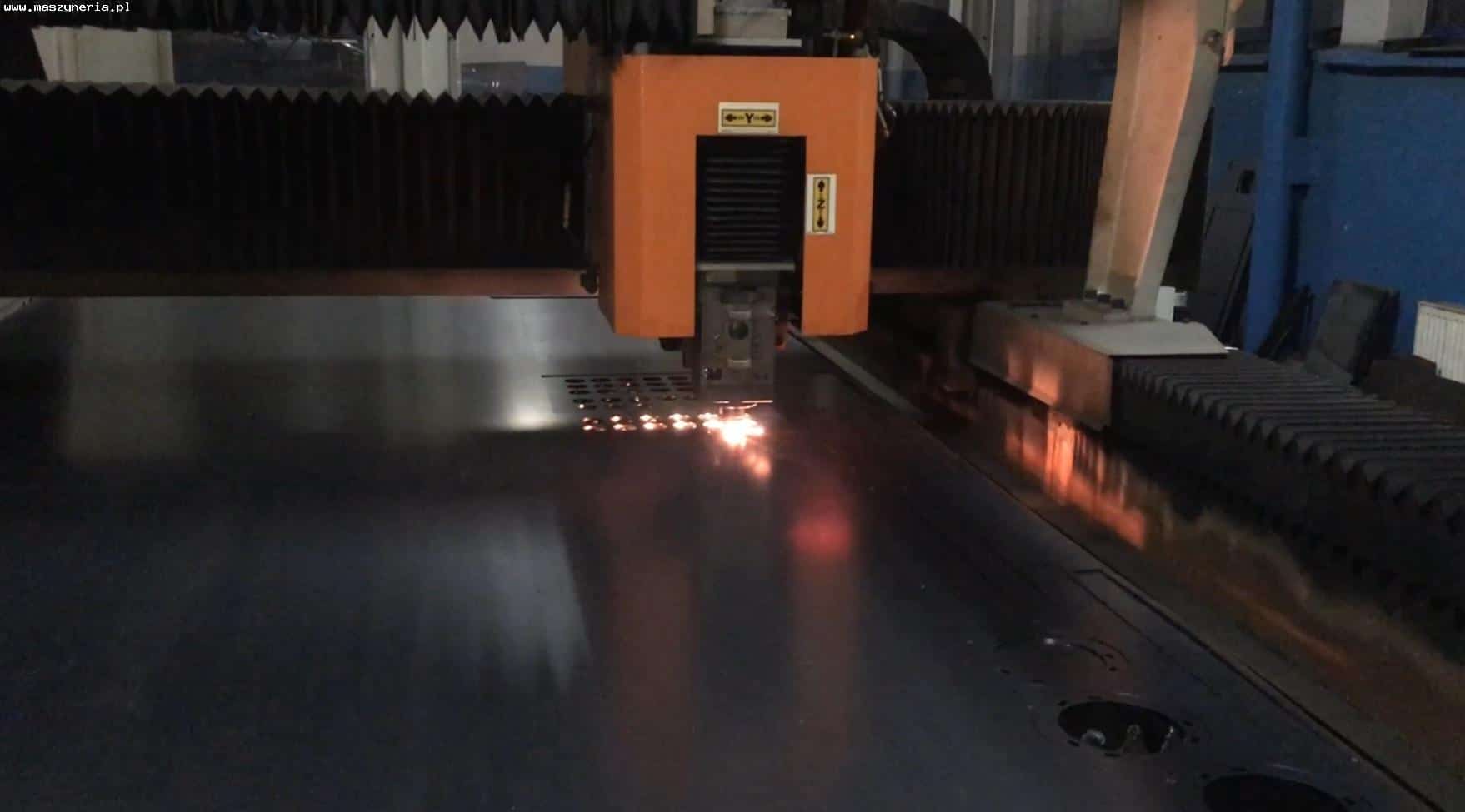

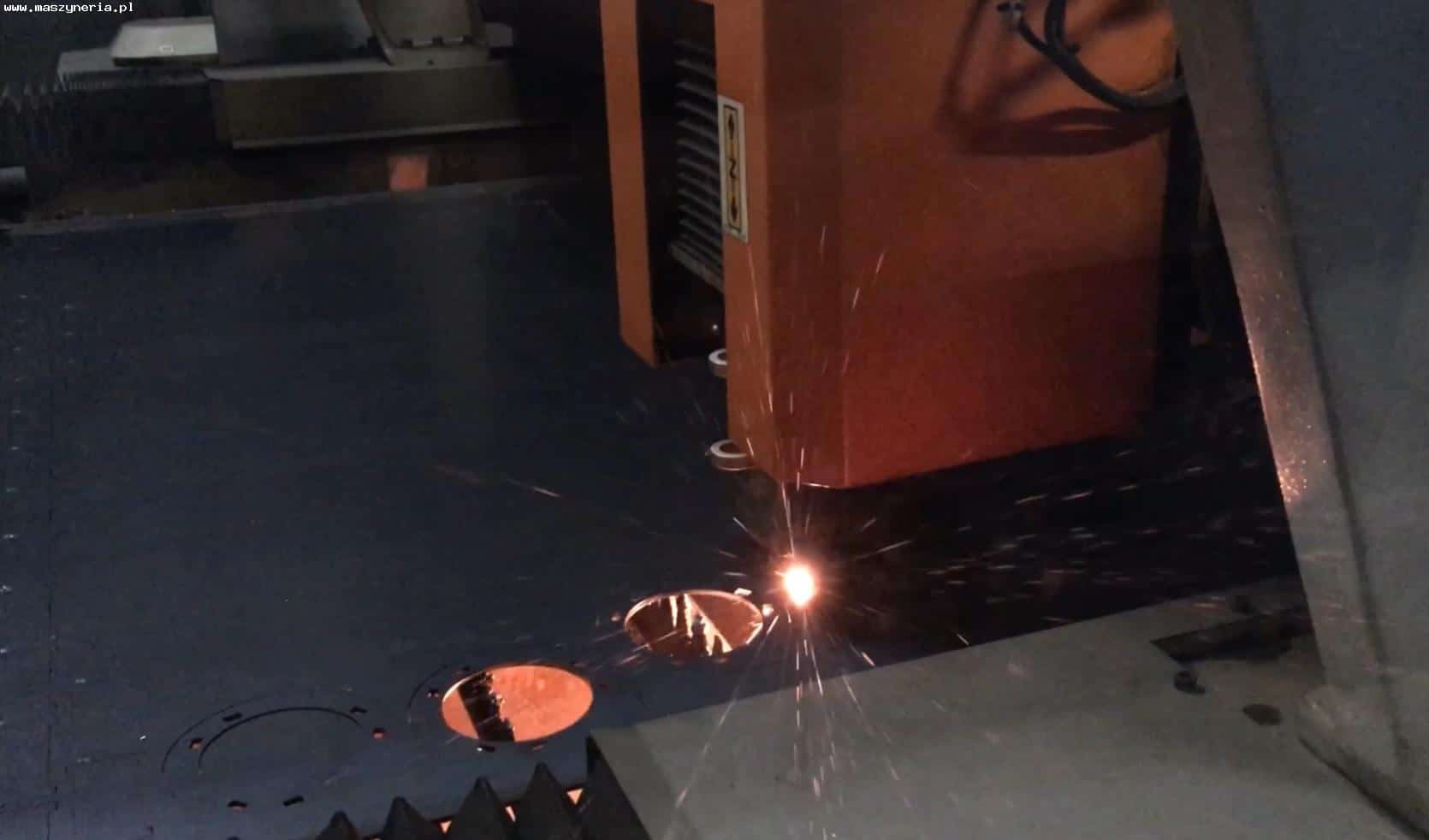

The ERMAKSAN LASERMAK 4000.3 x 1.5 cutting laser laser cutter with a power of 4 kW was built in Turkey in 2011. The laser is equipped with FANUC Series 16i-LB numerical control, two interchangeable work tables with a size of 3000×1500 mm, a FANUC resonator and linear motors. The power of the source is 4000 W, which enables cutting sheets with a maximum thickness of 20 mm (ordinary steel).

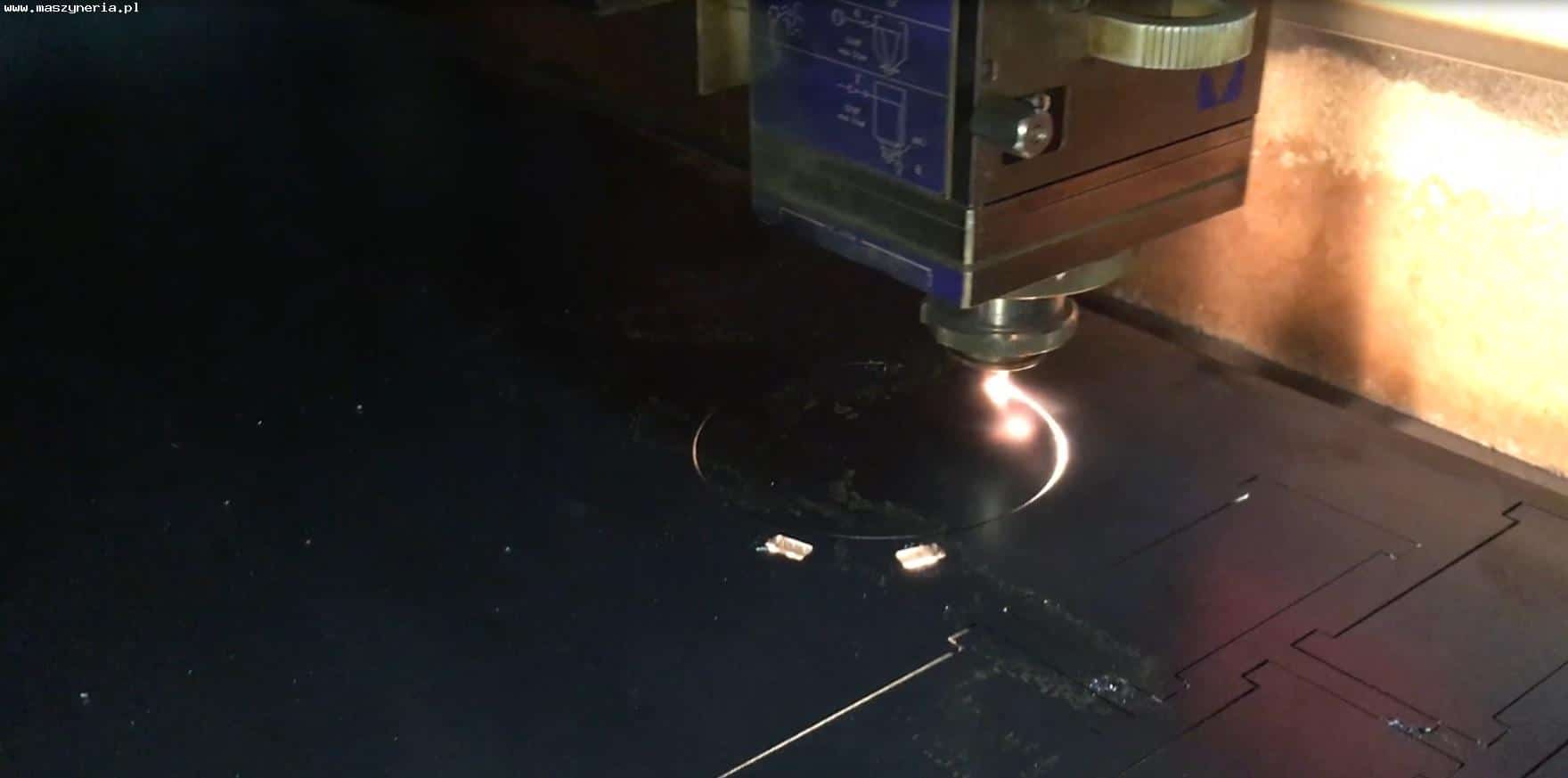

The Lasermak frame and components are specially machined on CNC machining centers with maximum precision, which allows for excellent cutting results. The laser cutter is equipped with linear motors which are optional specification for other companies. The axis moving with strong magnets mounted on the frame guarantees high speed and maximum acceleration (Y axis 3G). In turn, high speed and acceleration guarantee increased efficiency and productivity while reducing operating costs. The gate and machine frame are assembled and tested at every stage of the production process using the most modern measurement technologies. This is the main reason for excellence in square and round cutting. In this way, there is no need for additional operations, and Lasermak produces parts ready for assembly.

Technical data of the ERMAKSAN LASERMAK 4000.3 x 1.5 laser cutter

– laser power: 4 kW

– maximum pulse power: 5kW (pulse peak power)

– laser beam working time: 7700 h

– table dimensions: 3000 x 1500 mm

– maximum cutting thickness, ordinary steel: 20 mm

– maximum cutting thickness, stainless steel: 12 mm

– maximum cutting thickness, aluminum: 8 mm

– maximum positioning speed: up to 170 m / min

– maximum acceleration: X axis 2G, Y axis 3G m / s2

– repeat accuracy: 0.015 mm

– positioning accuracy: + -0.03 mm

– Co2 / He / N2 gases can be used

– electric demand: 50-70 kW

– dimensions (L x W x H): 10470 x 5285 x 2430 mm

– machine weight ERMAKSAN LASERMAK 4000.3×1.5: 20800 kg

Equipment Lasermak 4kW

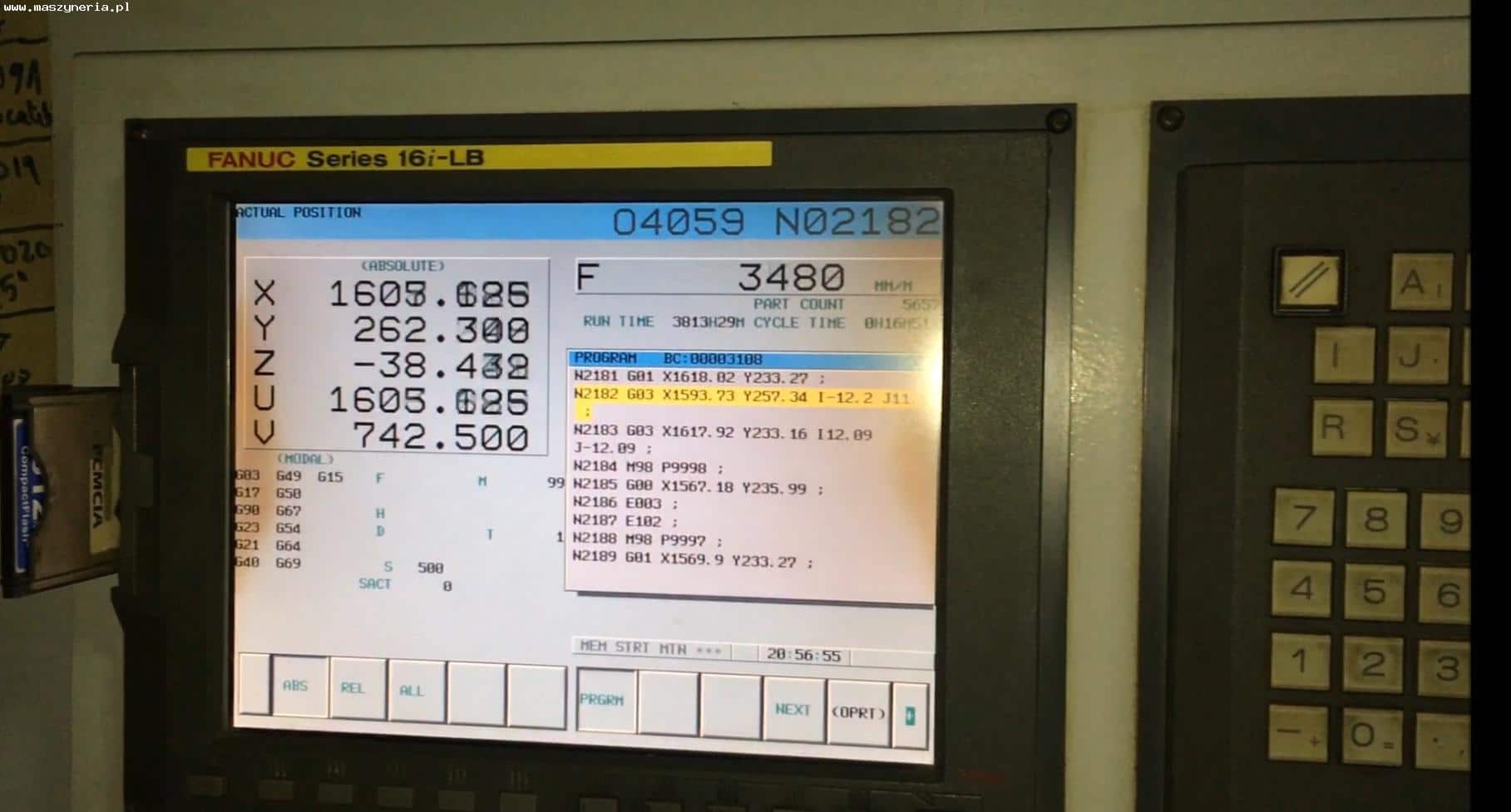

– CNC control: FANUC Series 16i-LB

– FANUC resonator (4000 W, CO2-Laser GR Fanuc C4000i-B, Short Optical Path Type)

– axes: X, Y, Z, U (X2), V (compensation axis)

– V axis: provides the best cutting result thanks to the constant beam path and compensation system. Synchronized with the bridge on the X axis. Thanks to this function, a perfect cut is obtained at every point of the table

– two interchangeable work tables

– linear drives

– cutting head: PRECITEC HP 1.5 “Z – HP 2” Z LASERMATIC CUTTING HEAD

– conveyor: placed under the machine frame, it transports details and waste

– gas extraction: independent absorption windows are synchronized with the cutting head. The suction port opens according to the position of the cutting head

– cooling system: cooling the laser source, optics, cutting head and linear motors

Fanuc 31i-LB numerical control

The Fanuc company is the world’s largest manufacturer of numerical controllers. In order to achieve maximum integration, the brand produces both resonators, CNC controls as well as linear motors.

– 10.4 “color LCD screen

– 2 MB part program memory

– inputs: Ethernet, USB or PCMCI

– programmable high speed to reduce cycle times

– high speed approach function

– easy access to cutting data tables

– edge, machining and starting functions

– integrated laser screens

– the control characteristics of the control can be changed using the settings

– ping-pong function. (very short hole-to-hole times)

– restart and return function.

– creating a program using the MDI panel

– time and cost calculation

CAD / CAM software: Lantek Expert

Lantek Expert Cut CAD / CAM software with Lasermak postprocessor has functions that optimize cutting with automatic nesting processing, cost / time calculation and micro-connections. Cutting data (cut, edge, pierce, power control) and technology graphs for each part can be registered directly in the part program by the Lasermak postprocessor. Thus, part programs created in Lantek can be transferred and run to the machine without changing the values to the CNC. What’s more, it has the function of making a hole of 0.5 sheet thickness and marking.

Additional features:

– Lantek includes a cutting data table for all material types and thicknesses

– automatic nesting and machining

– time / cost calculation

– CAD module

– MicroJoint feature that keeps the parts on the sheet after cutting

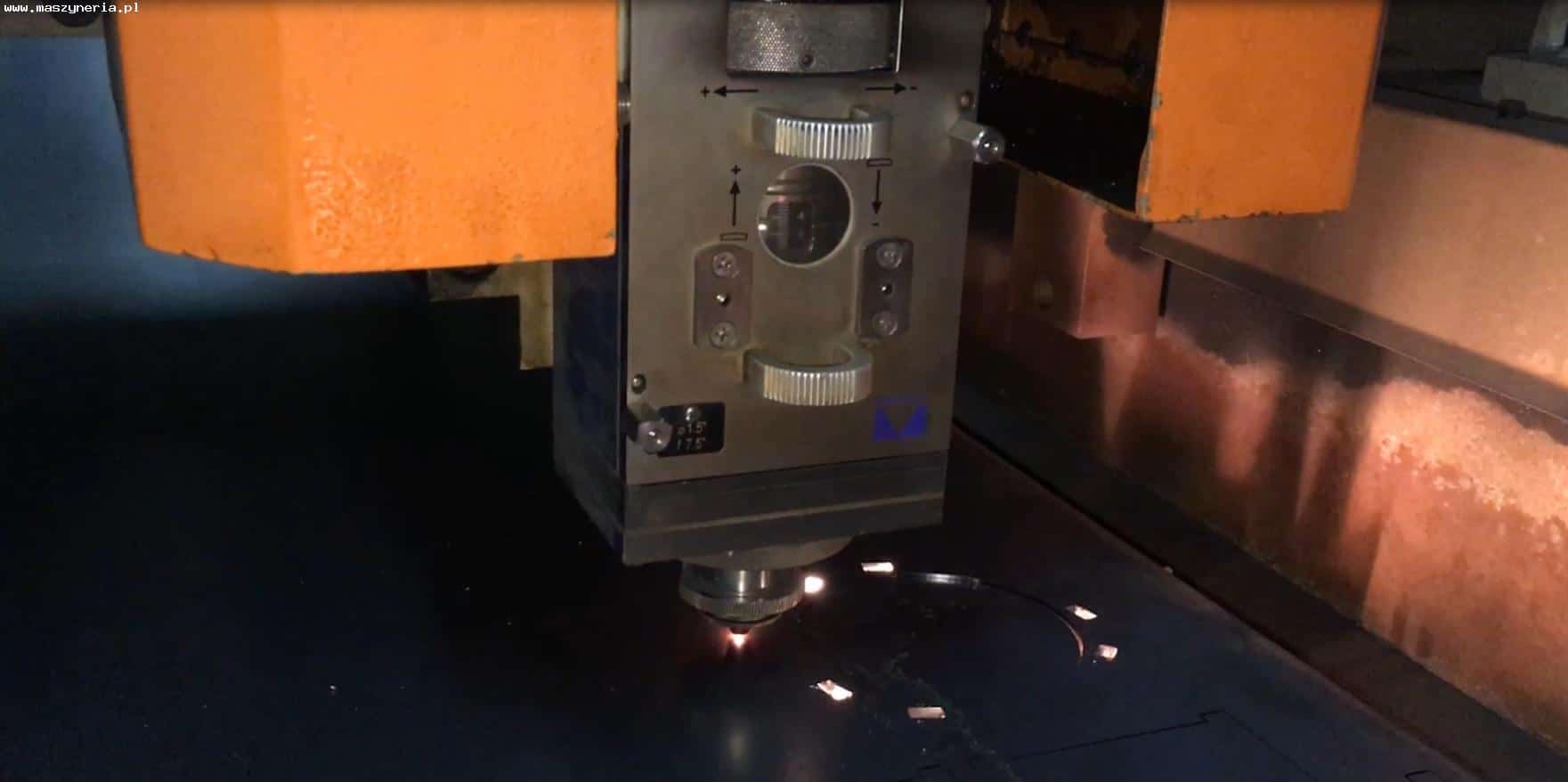

Cutting head: PRECITEC HP 1.5 “Z – HP 2” WITH LASERMATIC

Plug and play cartridge system for high pressure cutting. The cartridges on which the lenses are mounted are extremely practical and easy to use. Changing the material thickness takes just a few minutes to set new parameters ready for the next cut. 3.75 “, 5”, 7.5 “, 10” focal lengths (with extension adapter) guarantee two replaceable cartridges on the cutting head.

– cooling system

– two auxiliary gas connections

– a compact replaceable cartridge (dual focal length) from -10mm to + 5mm provides many cutting advantages

– the cutting head can operate at high gas pressure up to 25 bar (2.5 MPa)

– the integrated distance sensor control always keeps the same distance between the sheet and the nozzle.

– error signals protecting the cutting head against collision or cutting the cable

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano