The FANUC ROBOCUT ALPHA C600IA Z410 wire EDM machine was manufactured in 2016 in Japan. It is a modern Japanese electroerosion wire cutter. The Fanuc Robocut cutter is adapted to the processing of various machine parts, e.g. dies, dies, punches, as well as parts with complex, complicated shapes and materials that are difficult to cut. This model was made to order and, unlike the standard model, has a travel of 410 mm in the Z axis. The new Robocat Alpha C600IA wire cutter currently costs 150,000 Euro net from the manufacturer. The cutter presented here was used sporadically in the tool shop for the production of prototypes and is in very good technical condition.

Technical parameters of the FANUC ROBOCUT ALPHA C600IA Z410 EDM machine

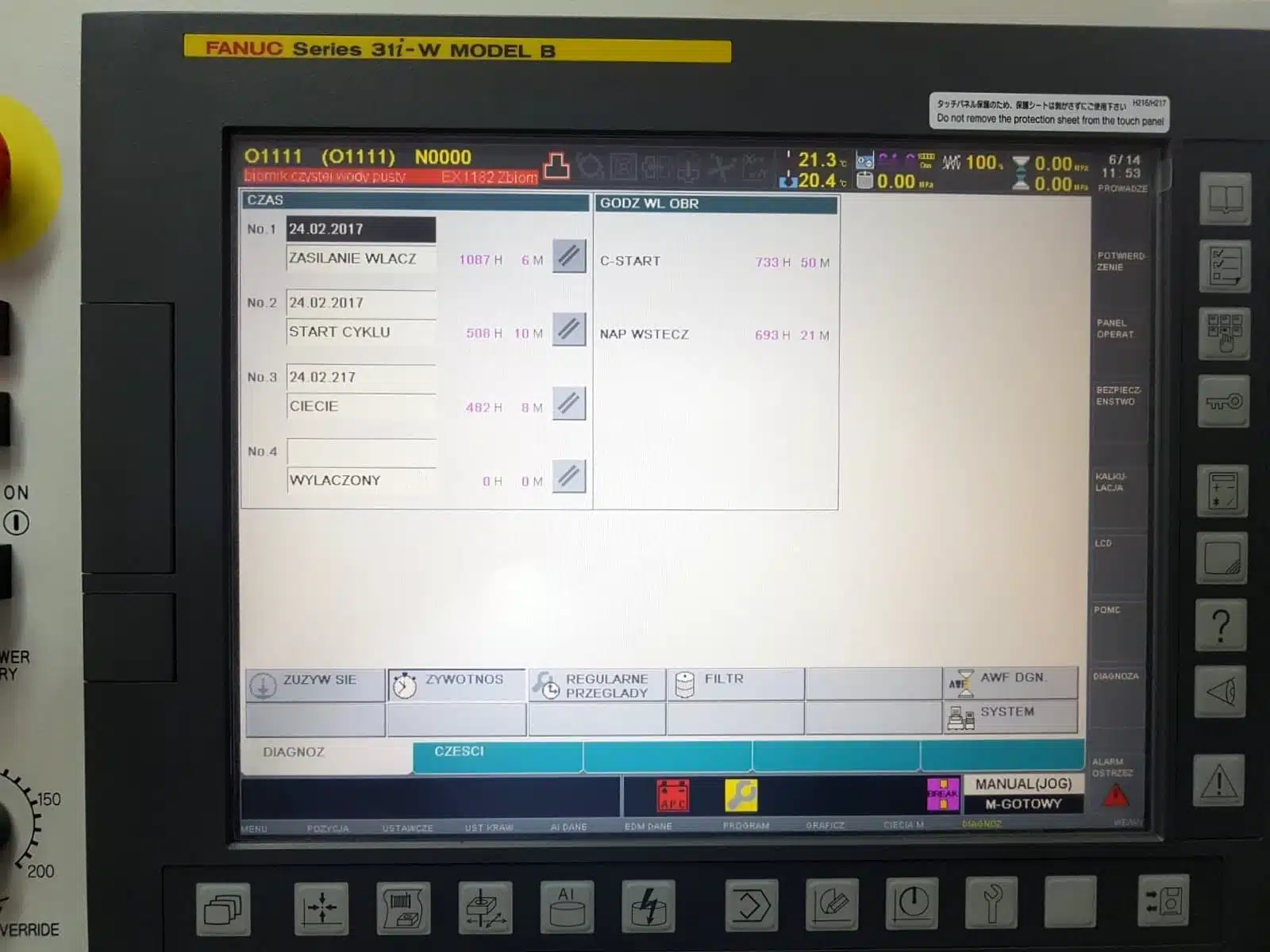

– CNC control: Fanuc Series 31i-W MODEL B

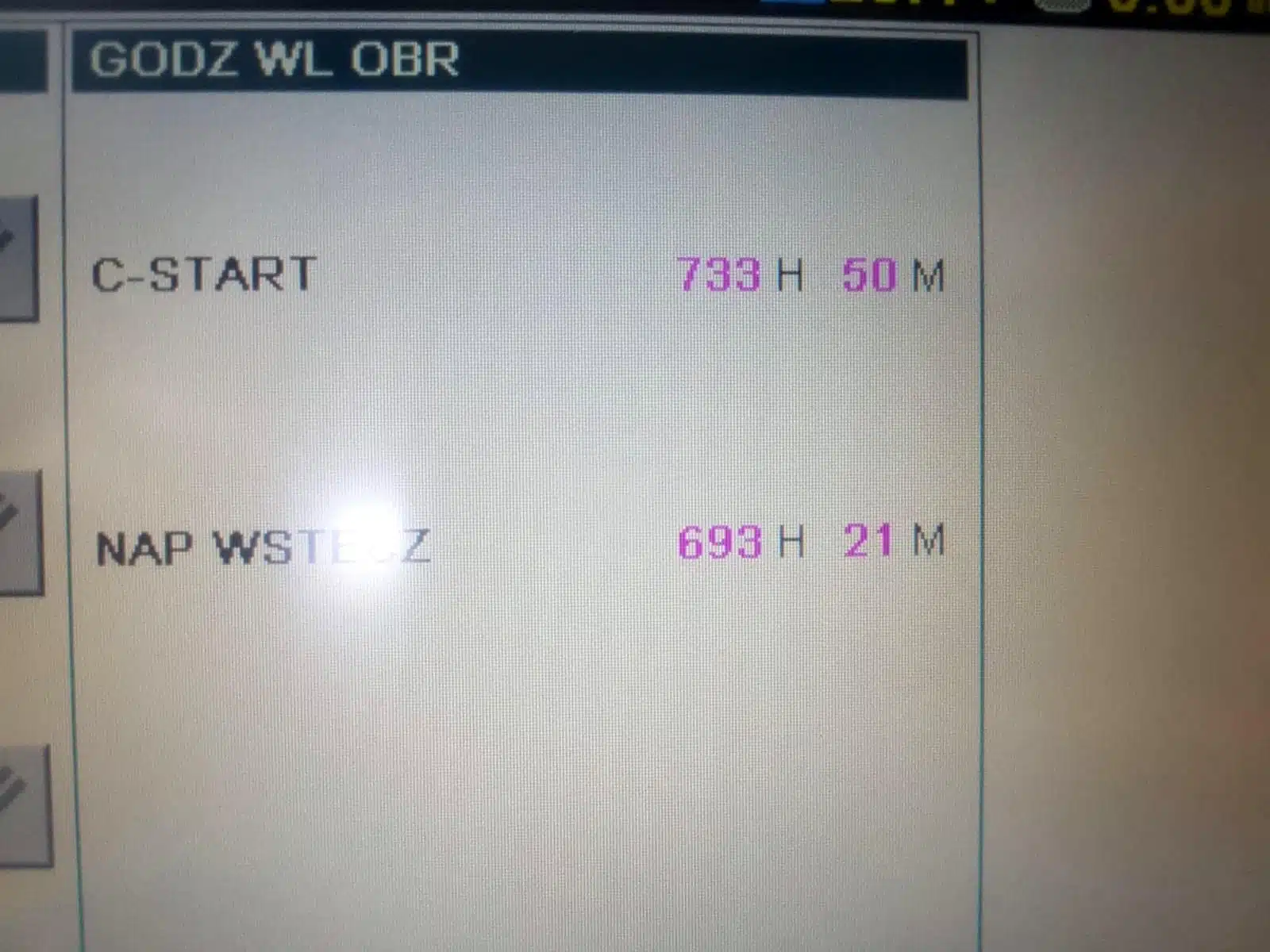

– machine time worked: 682 h

– hours of connection to electricity: 722 h

– maximum dimensions of the workpiece: 1050 x 820 x 400 mm

– maximum workpiece weight: 1000 kg

– X, Y axis travel: 600 x 400 mm

– Z axis travel: 410 mm (length selected from the manufacturer’s additional options)

– U, V axis travel: +100 mm x +100 mm

– wire diameter: 0.1-0.3 mm

– maximum wire slope: +/- 30 degrees / 150 mm

– surface roughness obtained after treatment: Ra = 0.30 µm

– AI corner cutting control system

– additionally: a cooling unit that stabilizes the parameters of the machining process (as an additional option for the machine from the manufacturer)

– additionally: 4 pcs of filters for about 300 Euro.