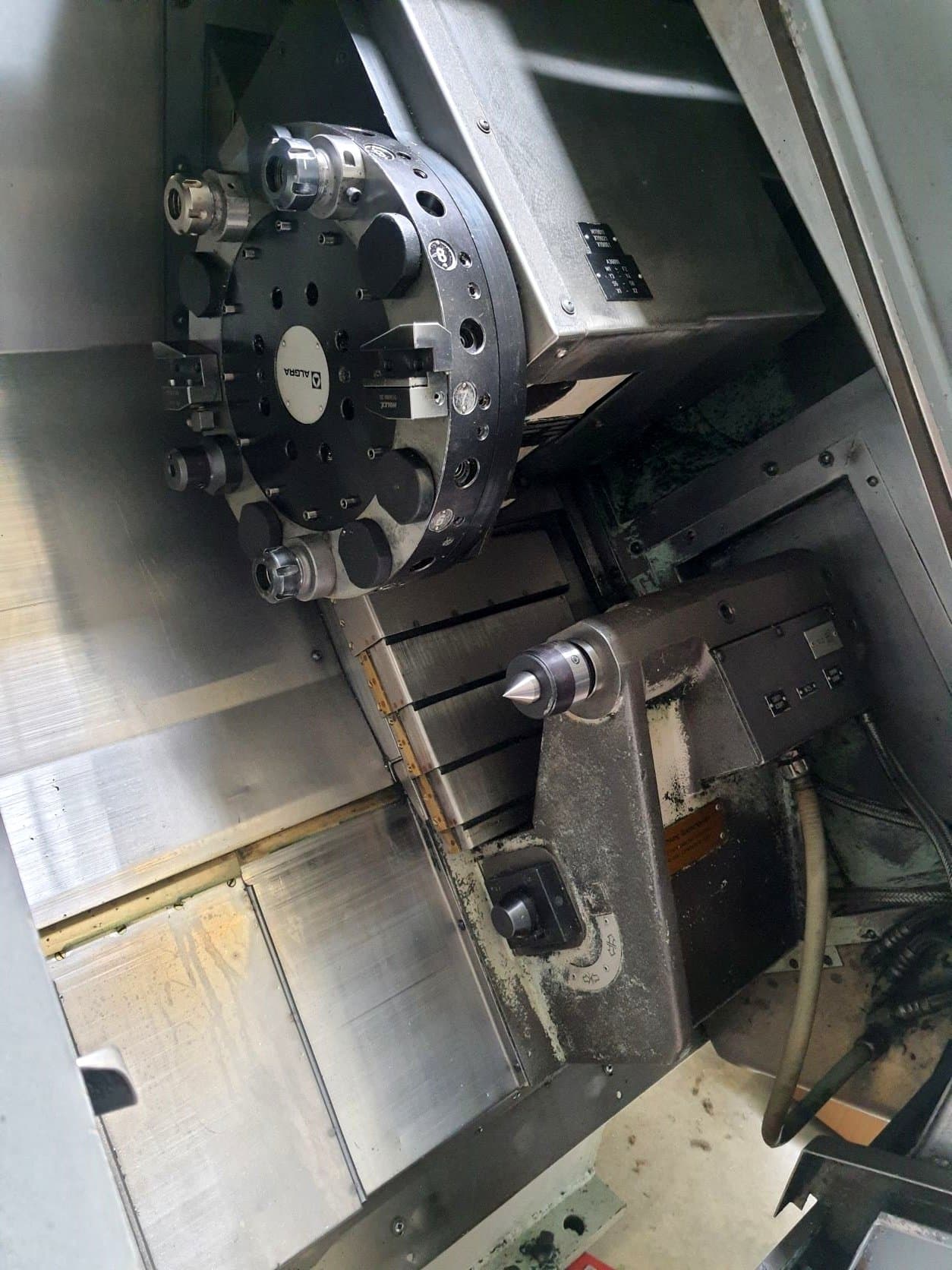

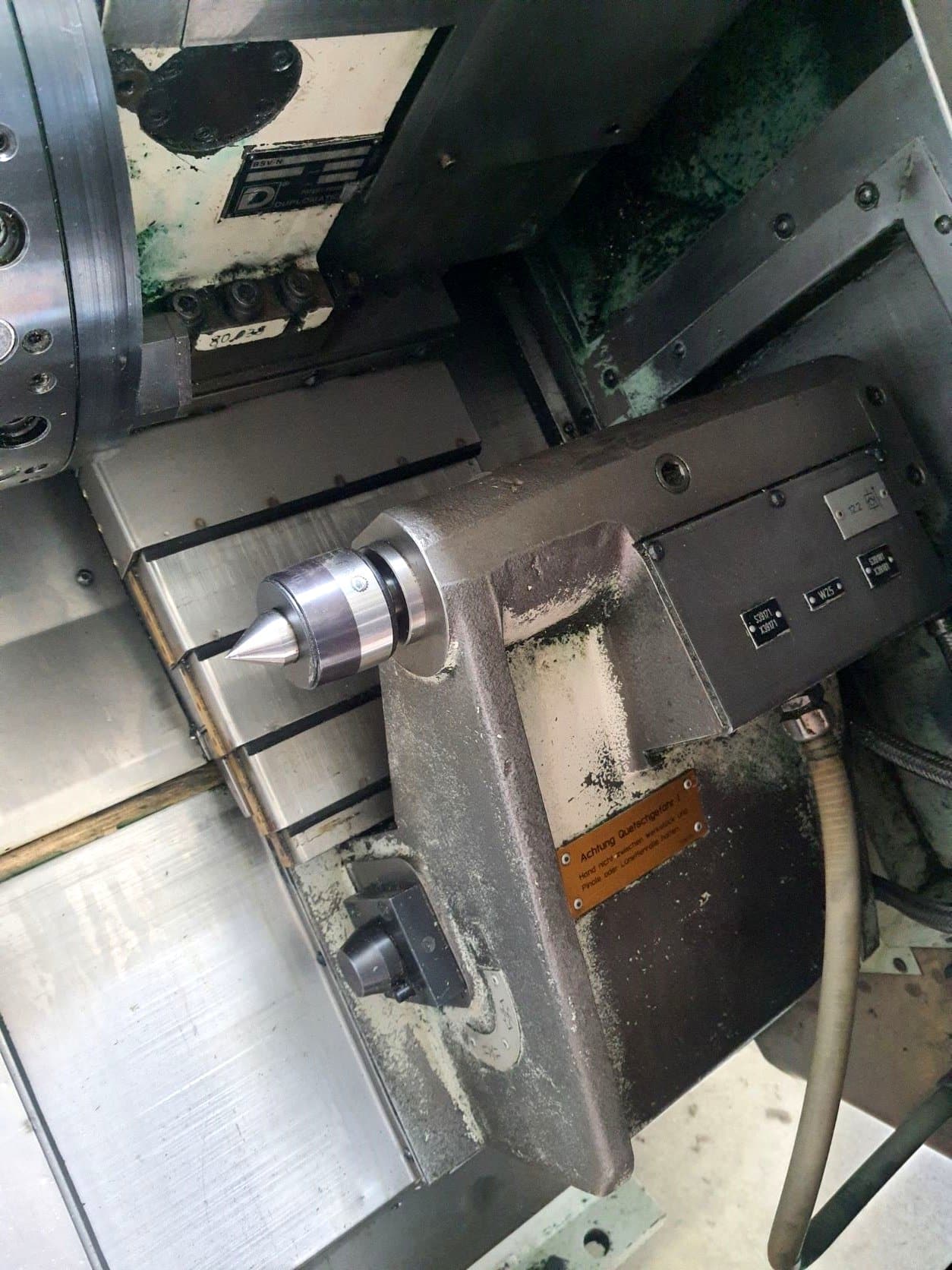

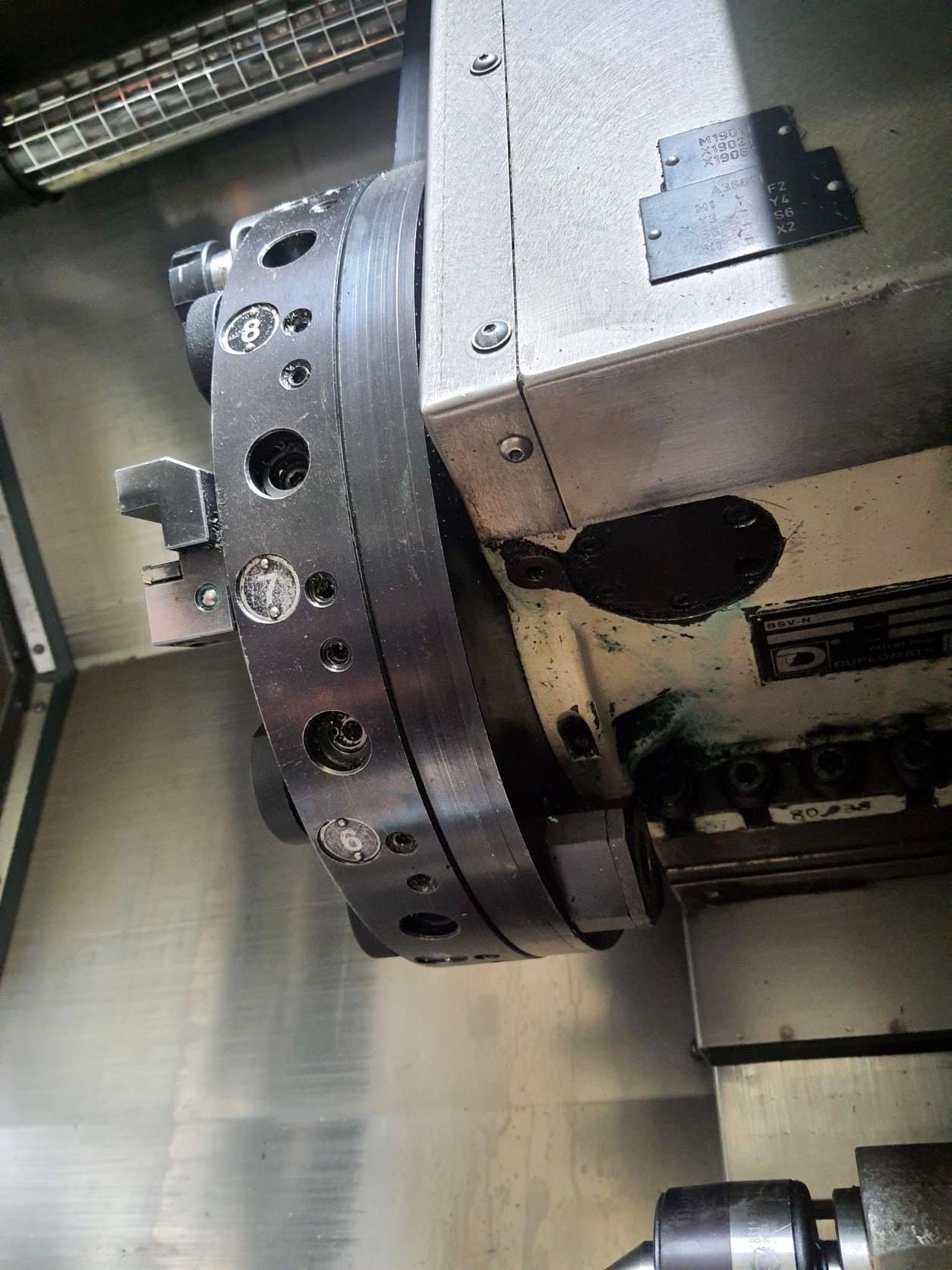

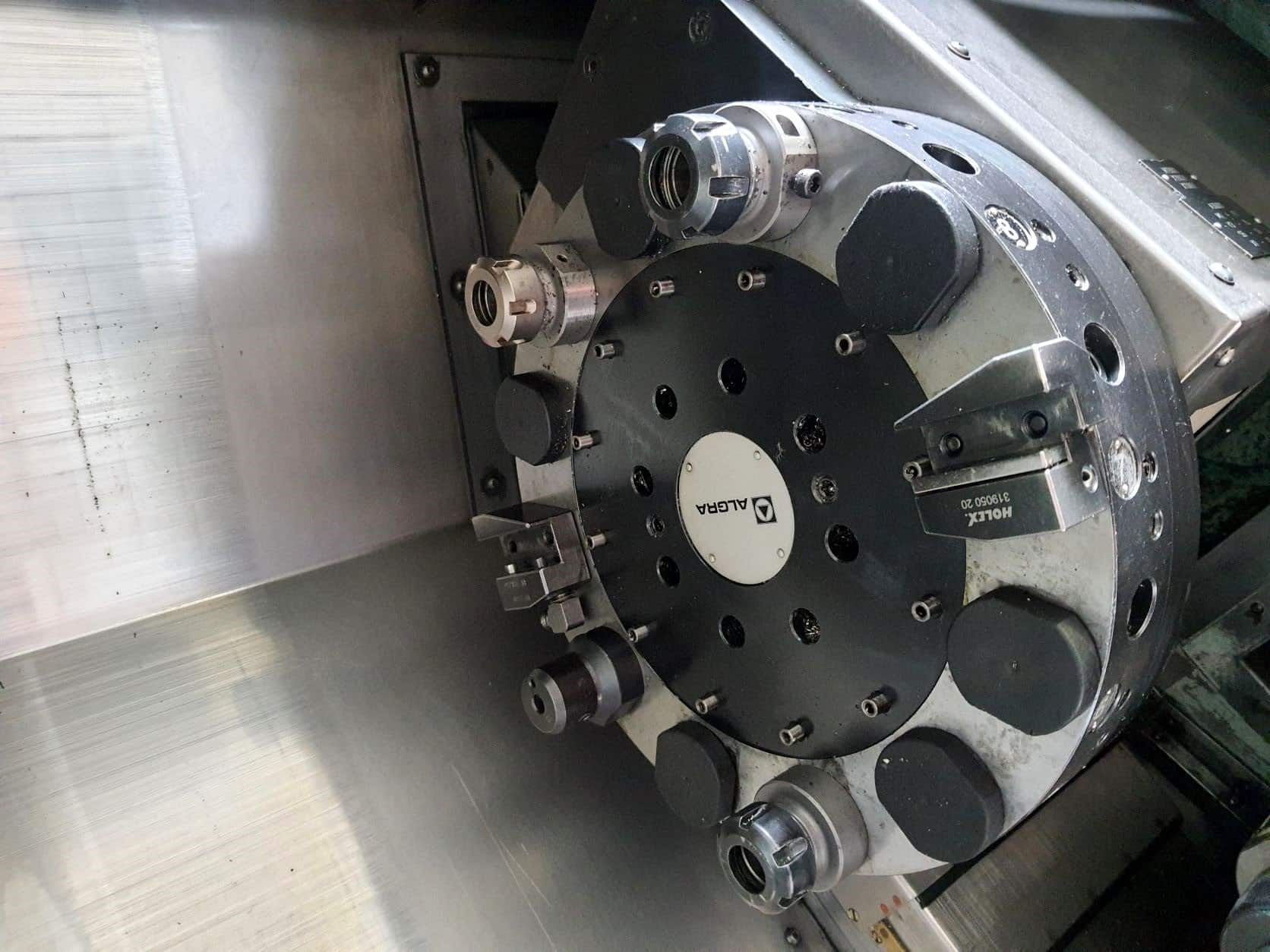

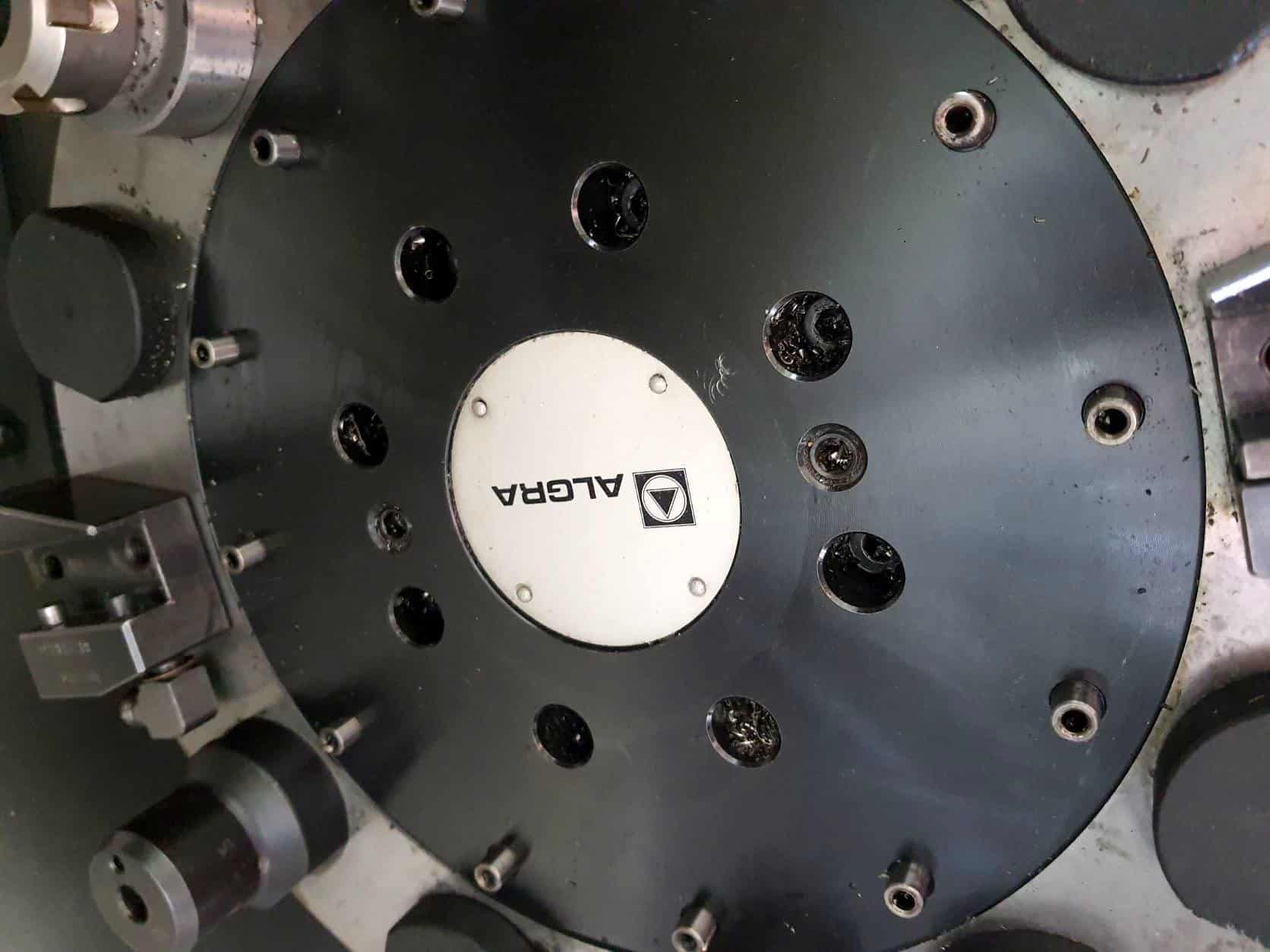

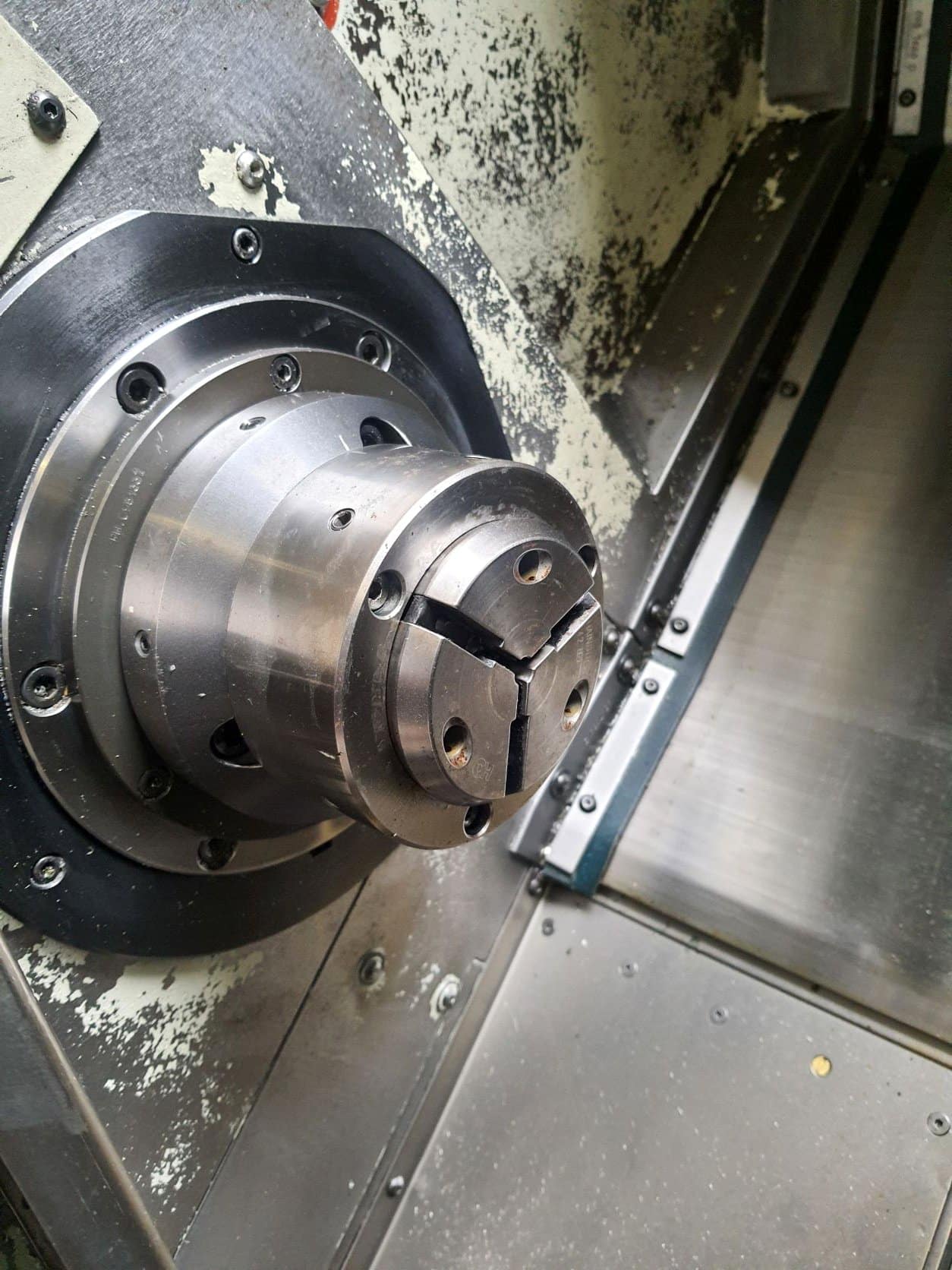

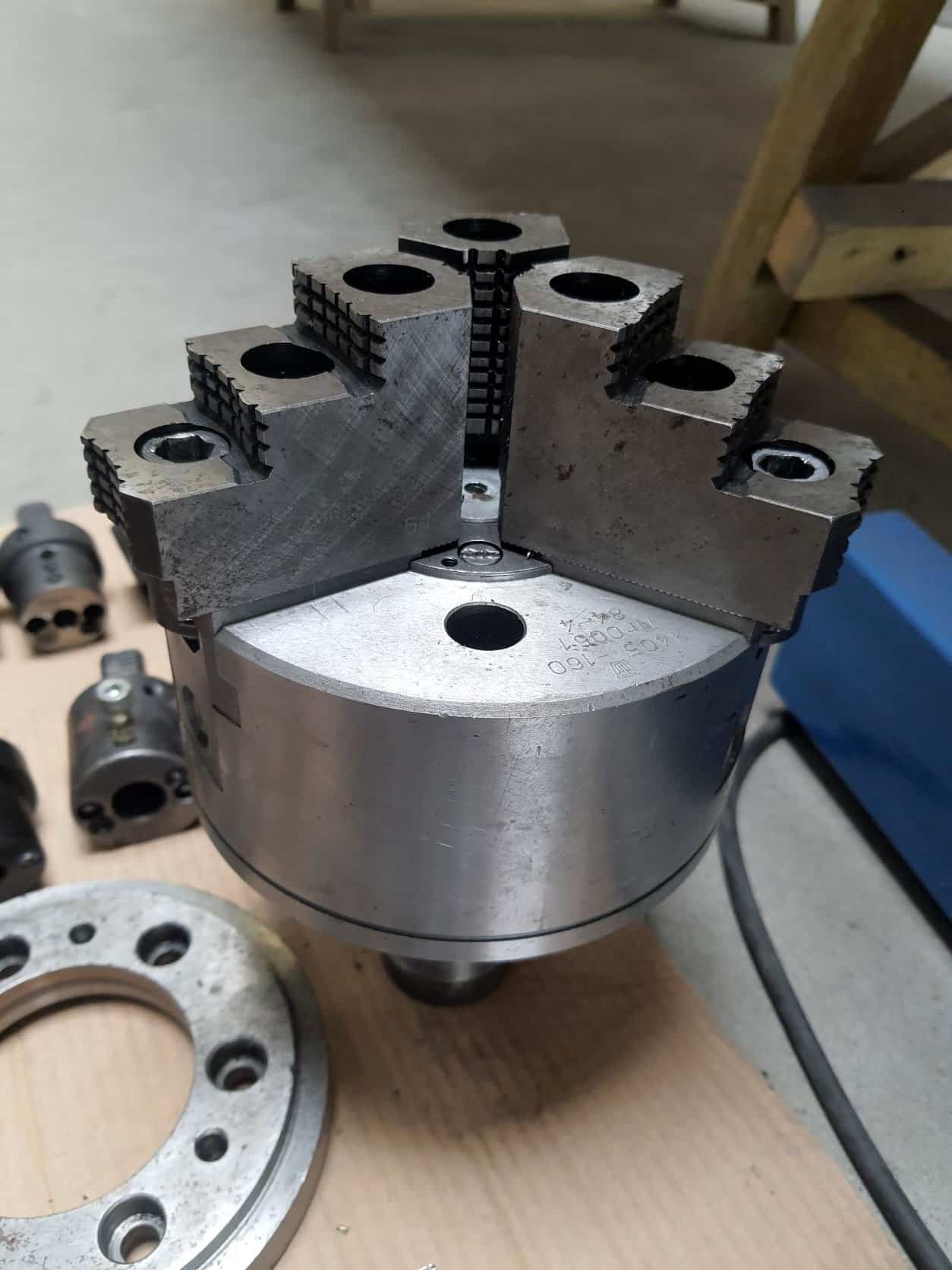

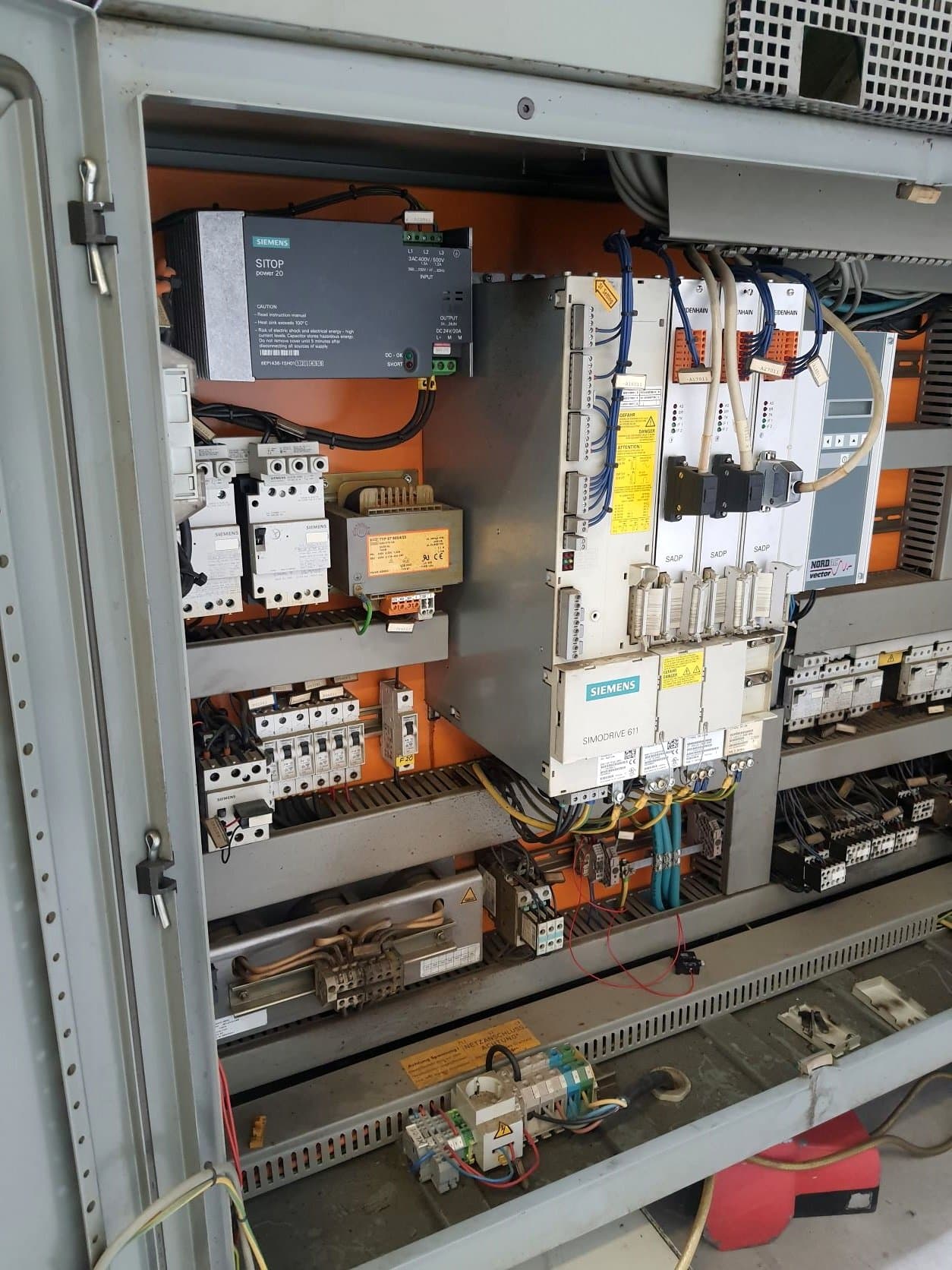

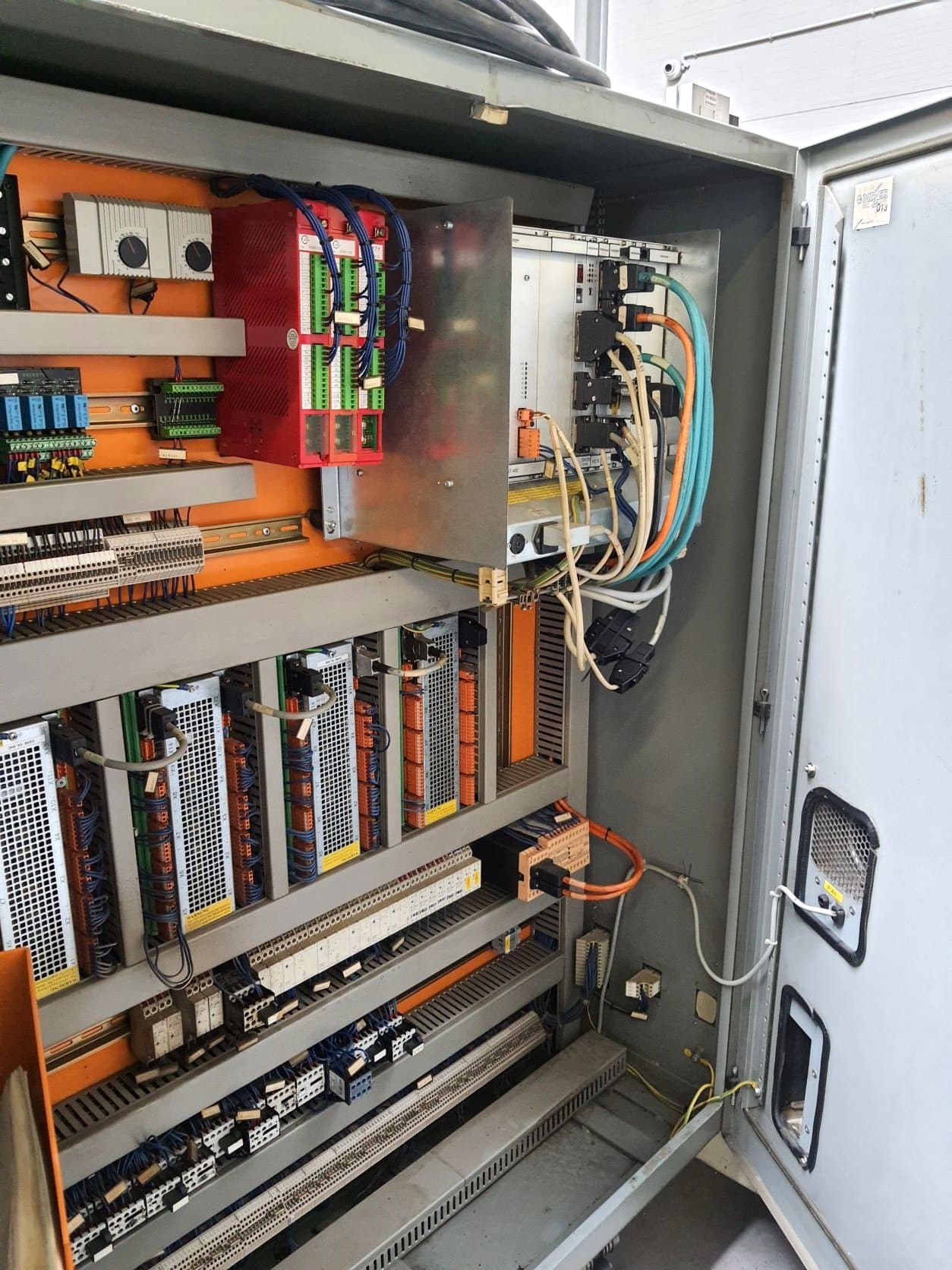

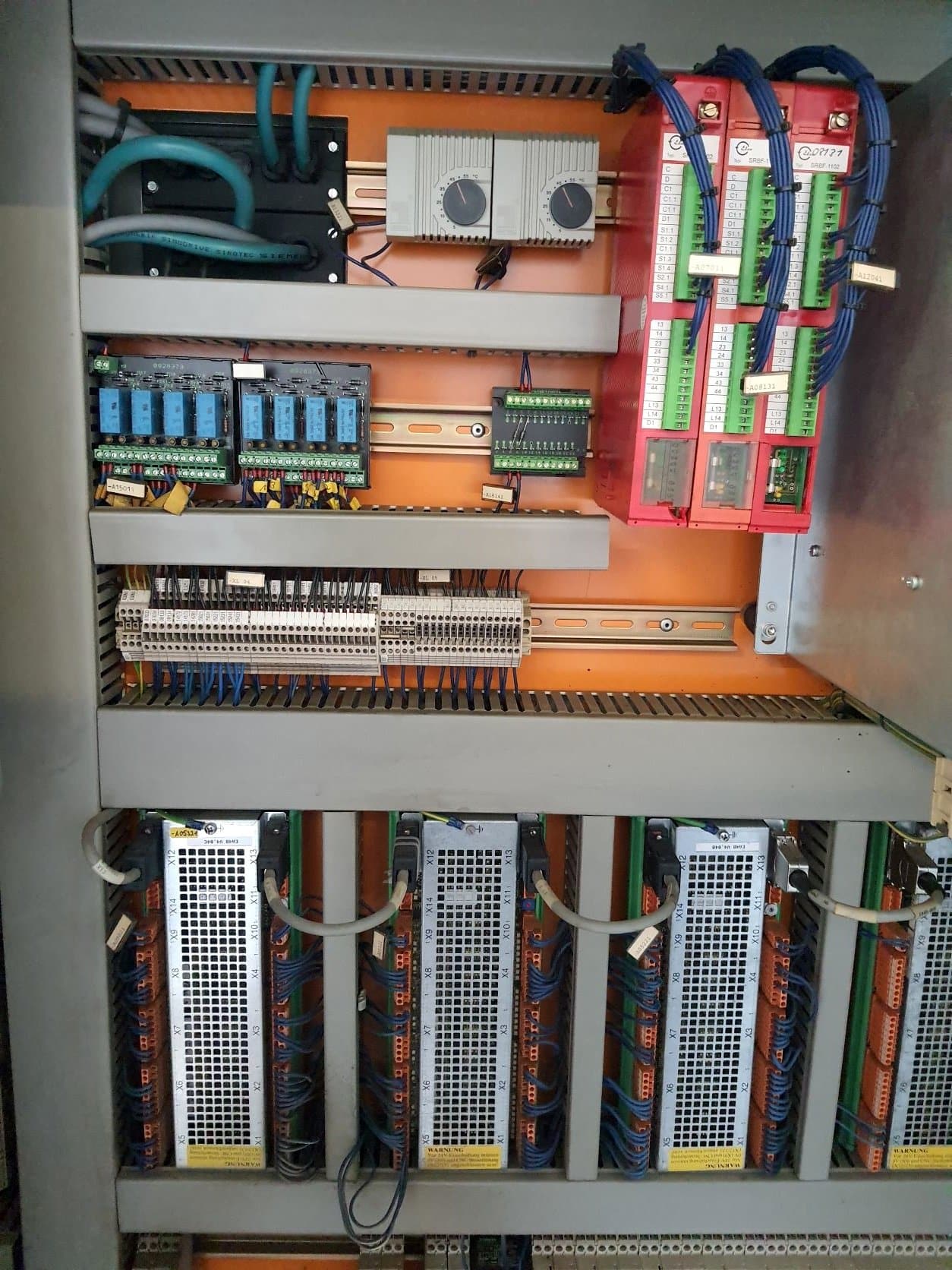

GILDEMEISTER CTX 200 CNC lathe was built in Germany in 1997. The machine’s purpose is the precise machining of metal workpieces with a maximum diameter of 210 mm and a length of 350 mm. The machine with its solid construction is equipped with a twelve-position tool head, allowing for a wide range of high-quality machining. The high-performance spindle of the turning centre rotates between 25 and 5000 times per minute and has a bore size of 56 mm.

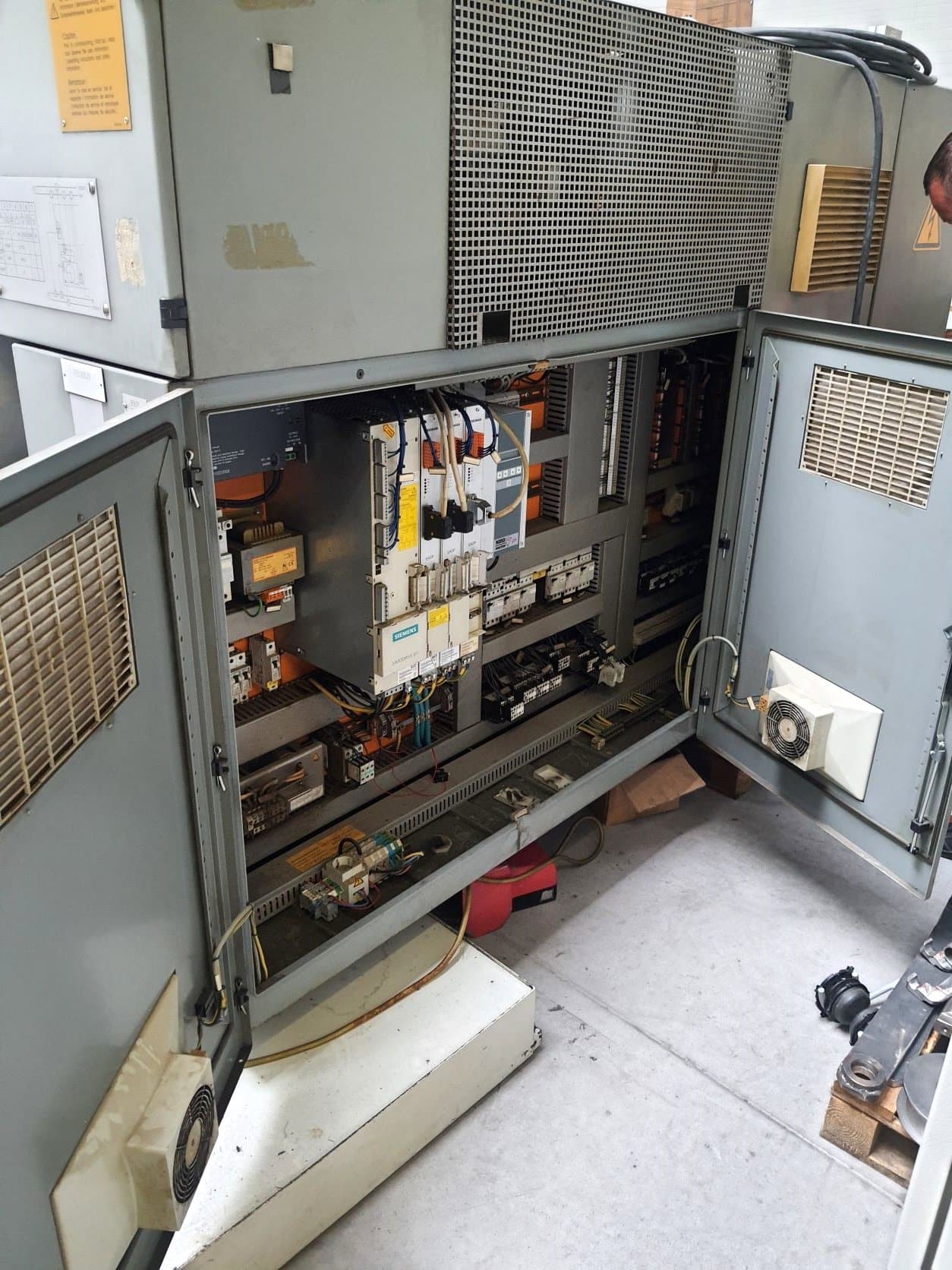

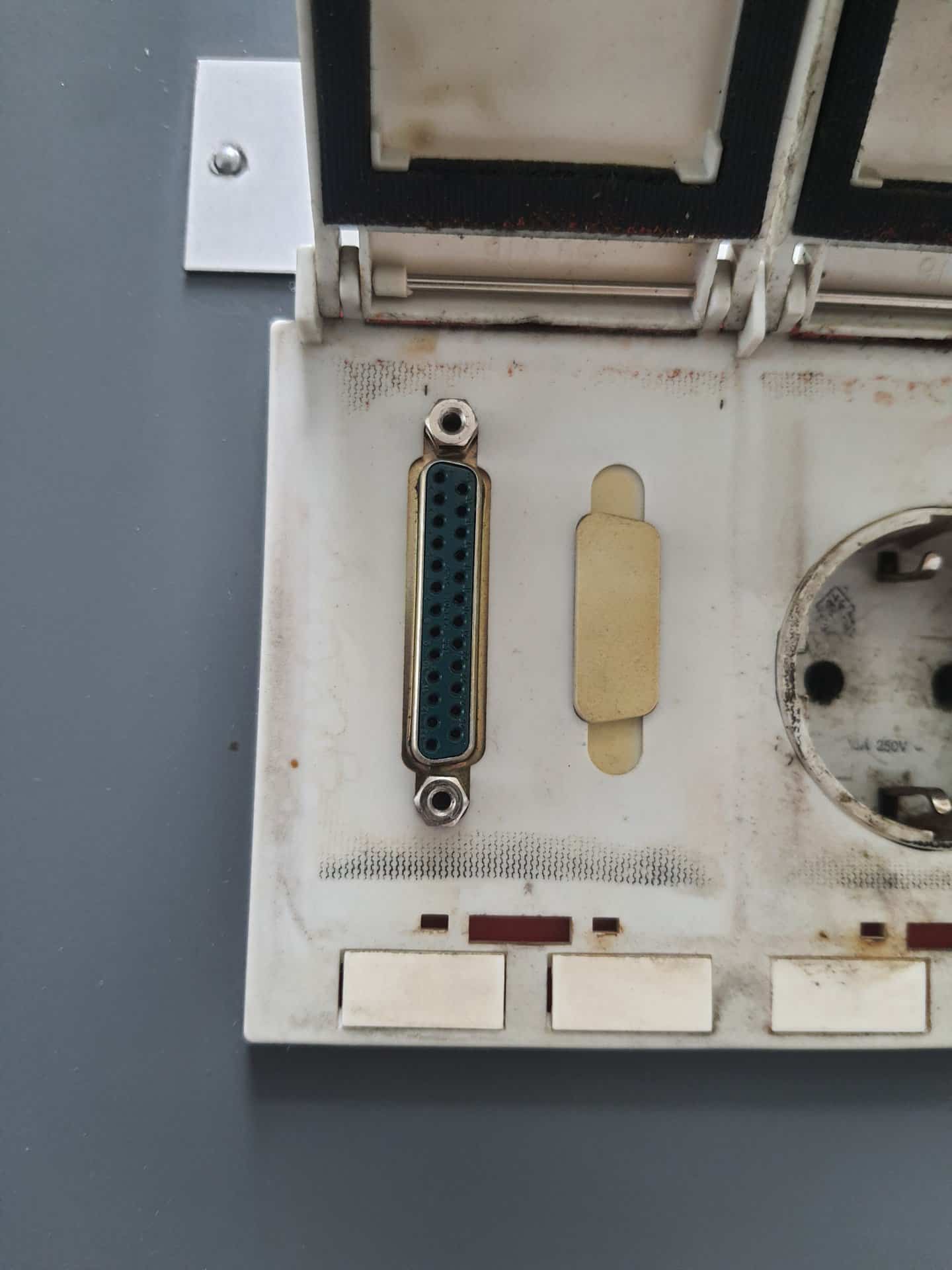

The lathe’s equipment also includes the HEIDENHAIN ELTROPILOT 1190 numerical control for programming turning processes with LCD screen, a chip conveyor and the LNS Quick load servo II bar feeder. The total weight of the machine is 2900 kg.

Technical parameters of the GILDEMEISTER CTX 200 turning machine

- maximum turning diameter: 210 mm

- maximum turning length: 350 mm

- X axis travel: 160 mm

- rapid traverse in the X/Z axis: 12/16 m/min

- tool magazine capacity: 12 pcs.

- minimum spindle speed: 25 rpm

- maximum spindle speed: 5000 rpm

- spindle bore: 56 mm

- spindle clearance: 42 mm

- toolholder type: VDI 20

- control language: English, German

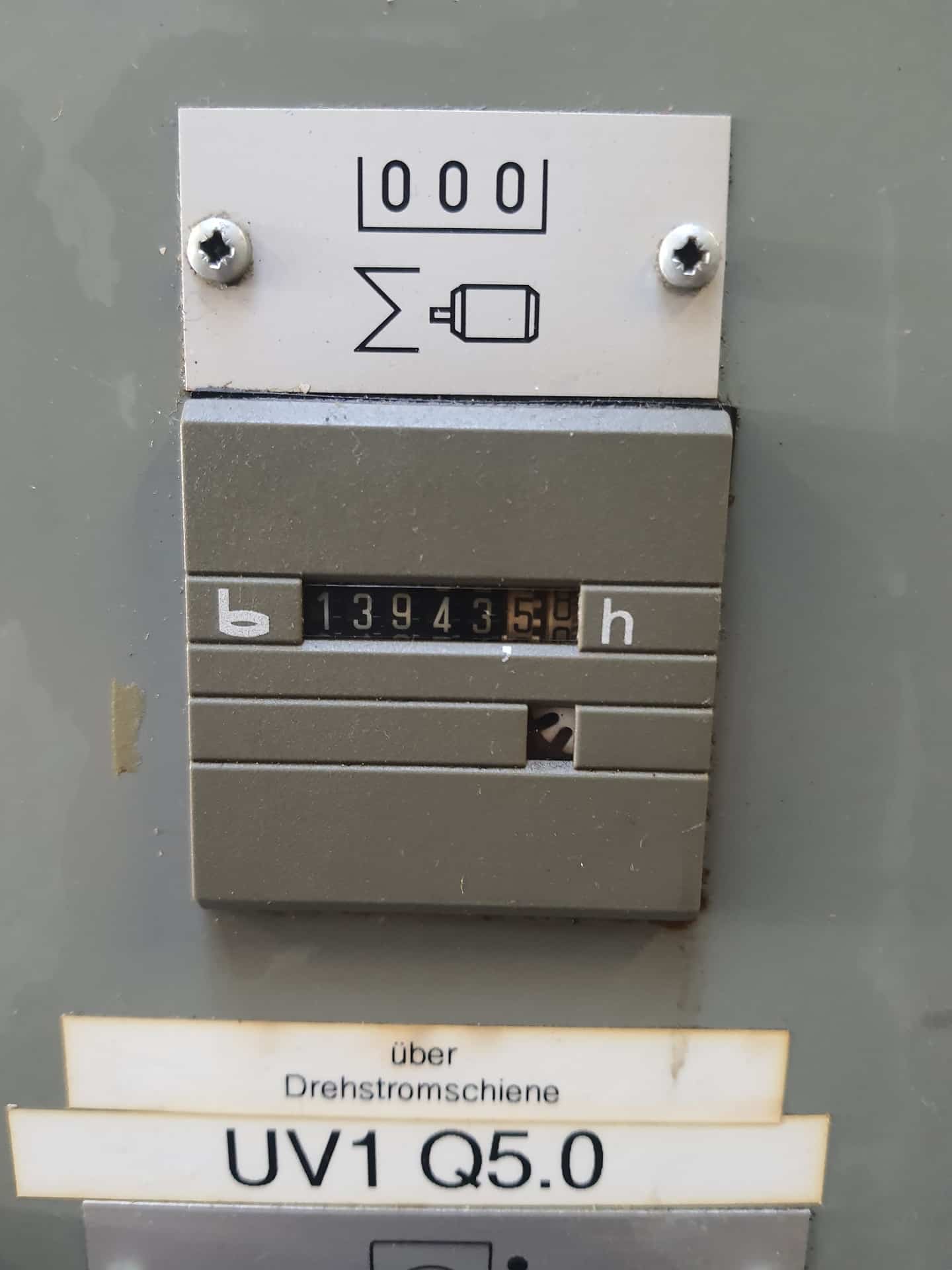

- operating hours: 13943 h

- dimensions of lathe with chip conveyor (L x W x H): 3930 x 1651 x 1690 mm

- total weight of the CTX 200 machine: 2900 kg

Equipment of the lathe

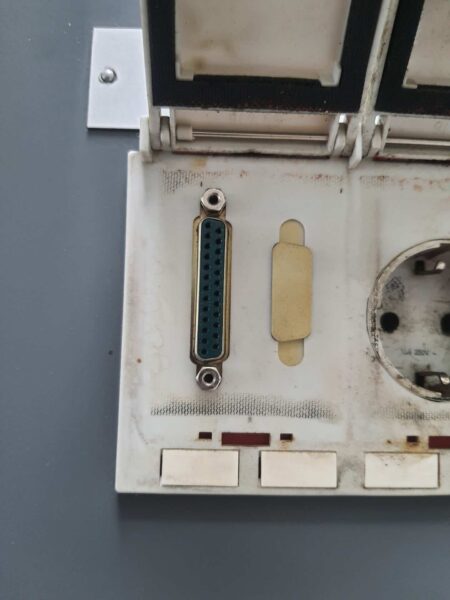

- CNC control: HEIDENHAIN ELTROPILOT 1190

- bar feeder: LNS Quick load servo II

- chip conveyor

- angle driven toolholders (3 pcs.)

- axial-powered toolholders (2 pcs.)

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe