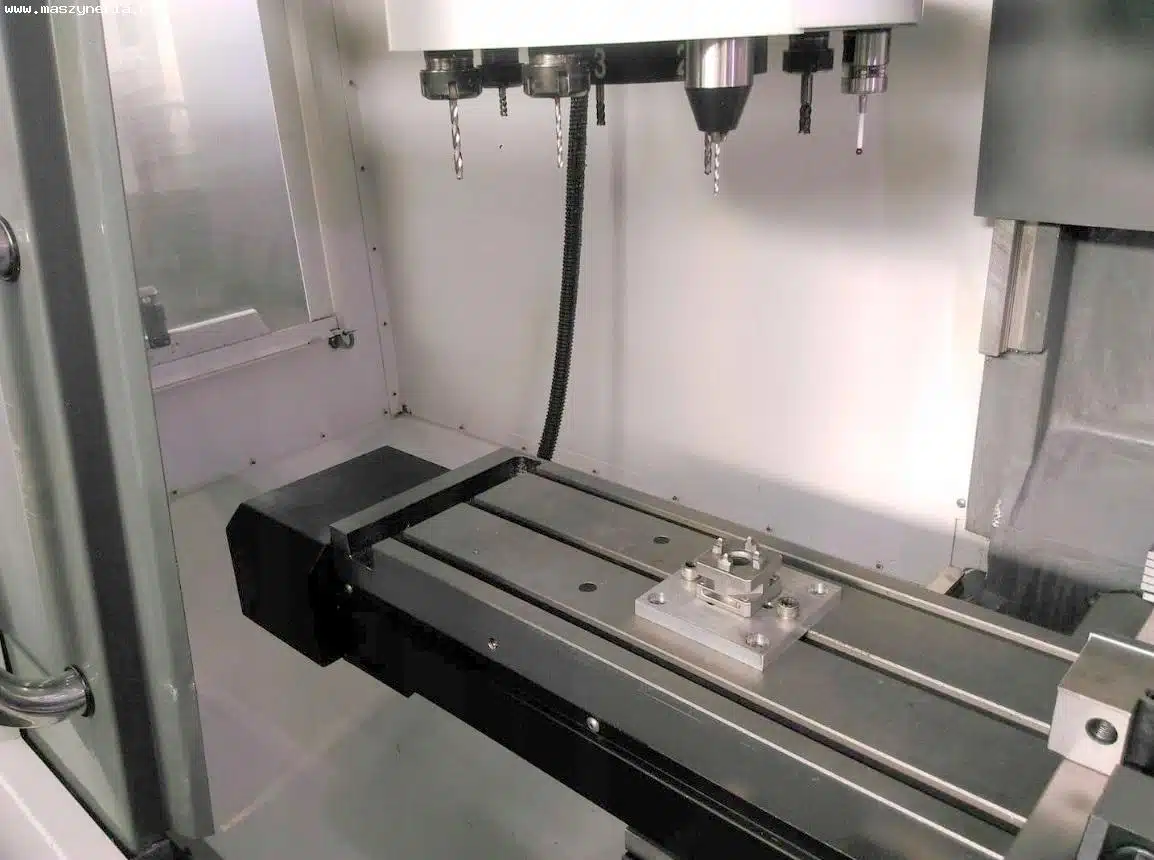

The HAAS TM 2P CNC milling center was produced in 2015. The Haas CNC milling machine has a 5.6kW spindle and a 10-tool magazine.

Technical data of the HAAS TM 2P CNC milling machine

– man-hours: 11,000 h

– X axis travel: 1016 mm

– Y axis travel: 406 mm

– Z axis travel: 406 mm

– from the end of the spindle to the table (maximum): 508 mm

– spindle nose to table (minimum): 102 mm

– maximum spindle power: 7.5 hp, 5.6 kW

– maximum speed: 6000 rpm

– maximum torque: 1200 rpm

– type of spindle drive: Direct Speed, Belt Drive, Direct Speed, Belt Drive

– spindle taper: CT or BT 40

– spindle bearing lubrication: Grease Packed

– spindle cooling: Air Cooled

– working table length: 1466 mm

– width of the working table: 267 mm

– width of the T-slots in the table: 16 mm

– distance from the center of the T-slots: 102 mm

– number of standard T-slot tables: 3

– maximum table load (evenly distributed): 454 kg

– X axis maximum motor force: 8896 N

– the maximum force of the Y axis motor: 8896 N

– maximum Z axis motor force: 8896 N

Feeder

– maximum cut: 10.2 m / min.

– speed of rapids on X: 10.2 m / min.

– speed of rapids on Y: 10.2 m / min.

– speed of rapids to Z: 10.2 m / min.

HAAS TM 2P CNC machining center tool magazine

– type: Carousel

– capacity: 10

– maximum tool diameter (full adjacent socket): 89 mm

– maximum tool weight: 5.4 kg

– tool change time: 5.7 s

– chip-to-chip tool change time: 6.5 s

Transport box dimensions

– national palette: 331 cm x 199 cm x 249 cm

– export pallet: 331 cm x 199 cm x 249 cm

– weight of the HAAS TM-2P machine: 2359 kg