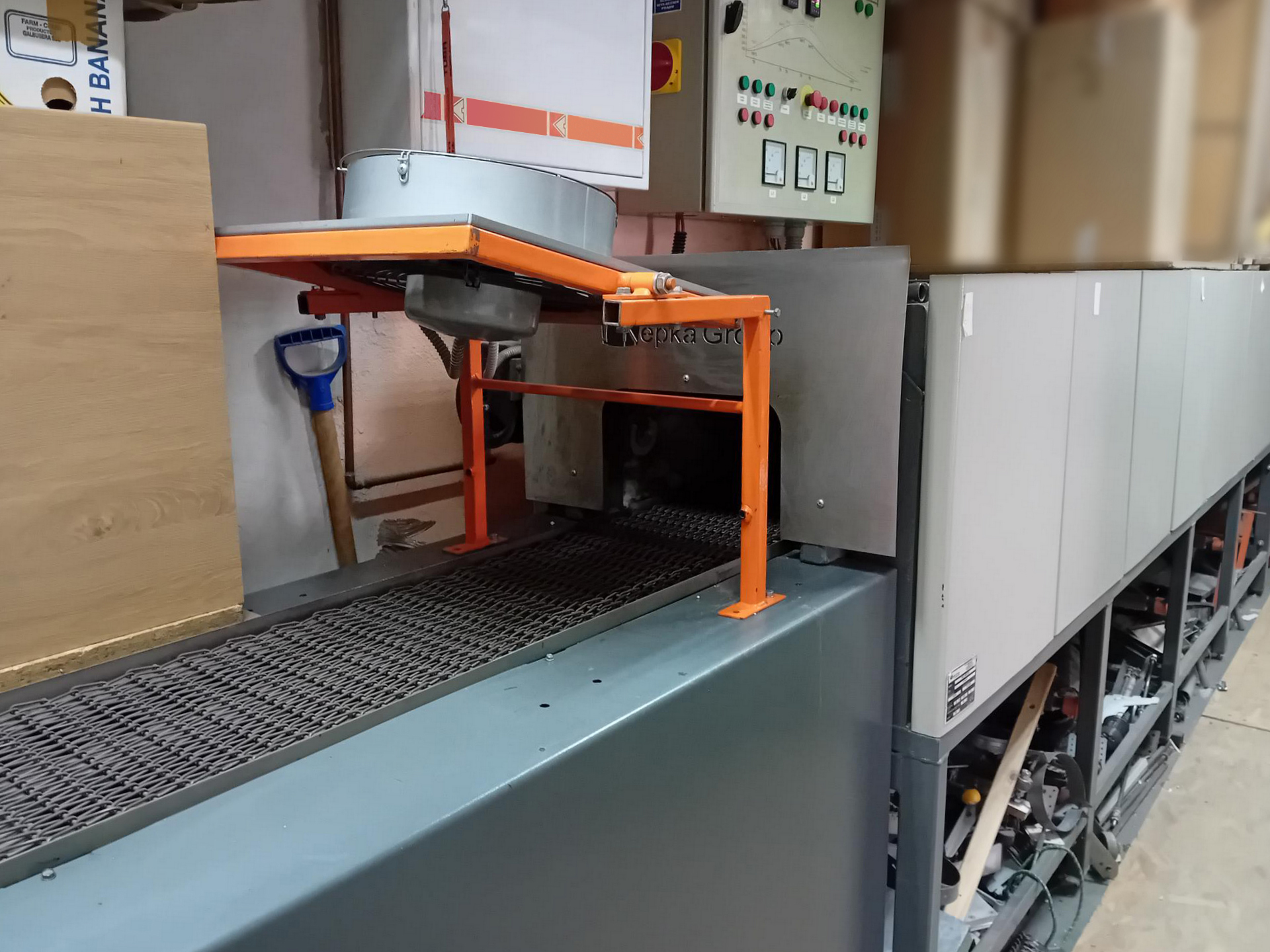

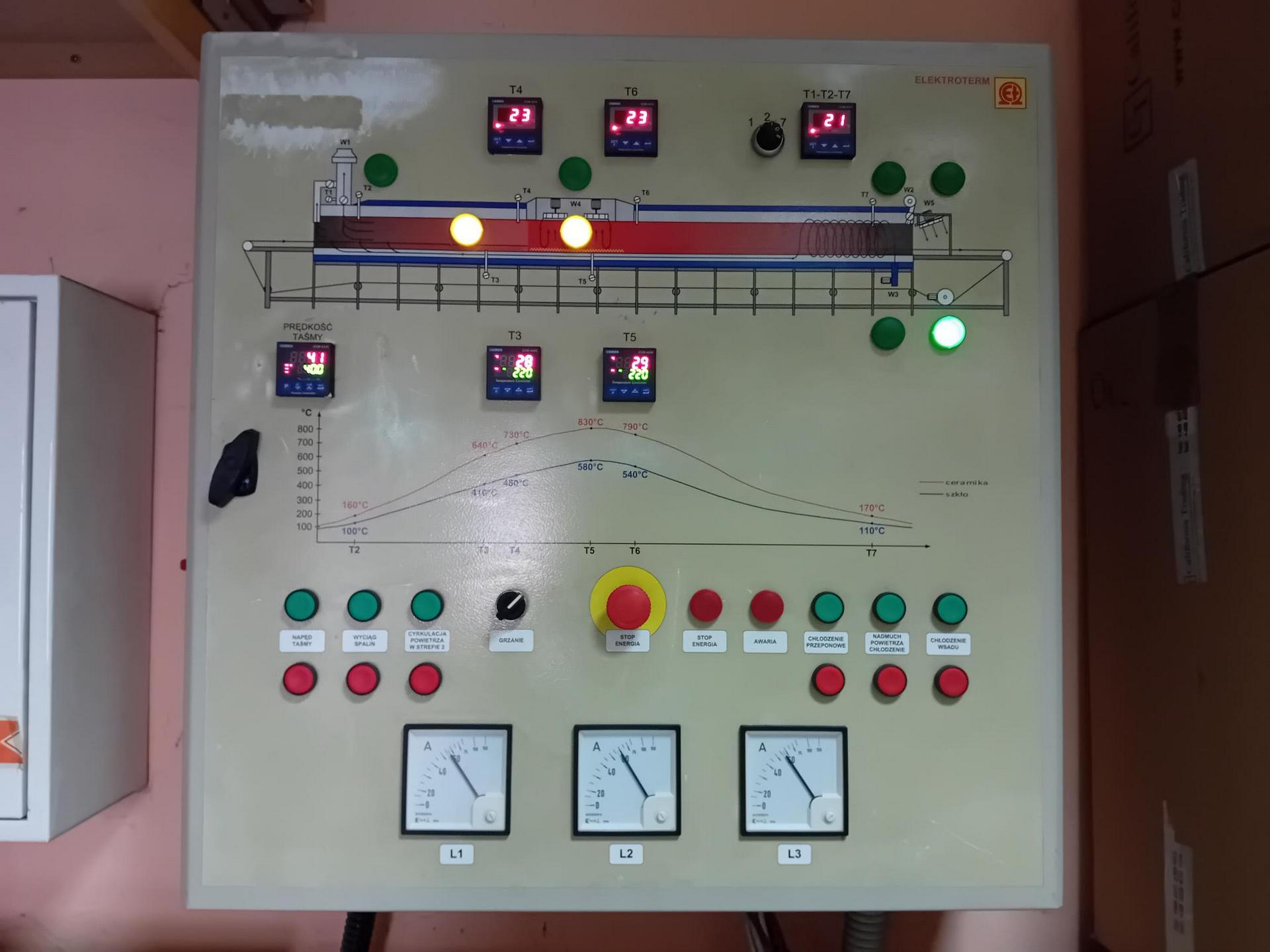

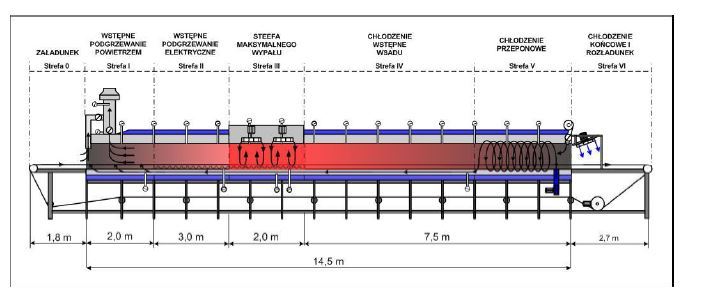

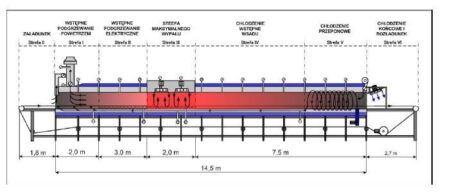

KEPKA CT 900 ET tunnel kiln was built in 2009 in Poland by the Kepka Group. The machine is designed for firing any type of decoration on glass and ceramics at a maximum temperature of 900°C. The working chamber is heated by a system of spiral heating elements arranged at the bottom of the preheating zone and the maximum firing zone. The proprietary heating system with a heat recovery system from cooling significantly reduces electricity consumption and therefore also reduces operating costs.

Thermal isolation in the form of an isolation plate and non-woven fabric is used along the entire length of the working chamber. This solution ensures optimum, very good working conditions, with adequate heat capacity and high mechanical strength of the entire system. The contaminants generated during thermal treatment are removed on an ongoing basis by a mechanical ventilation system in the form of a duct and exhaust fan. The CT 900 ET tunnel kiln weighs 2000 kg.

Technical specifications of the KEPKA CT 900 ET industrial kiln

- maximum operating temperature: 900°C

- maximum charge weight: approx. 120 kg

- working chamber volume: 0,9 m3

- working chamber dimensions (L x W x H): 14500 x 900 x 200 mm

- minimum firing time (3 mm glass): approx. 40 min

- minimum firing time (porcelain cup): approx. 120 min

- conveyor working speed: 0,06-0,4 m/min

- control: semi-automatic with precise multi-point temperature measurement

- power: 38 kW

- power supply: 3 x 400 V; 50 Hz

- space requirement (L x W): 22 x 5.5 m

- dimensions (L x W x H): 19000 x 750 x 1400 mm

- weight of the KEPKA CT 900 ET machine: 2000 kg

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe