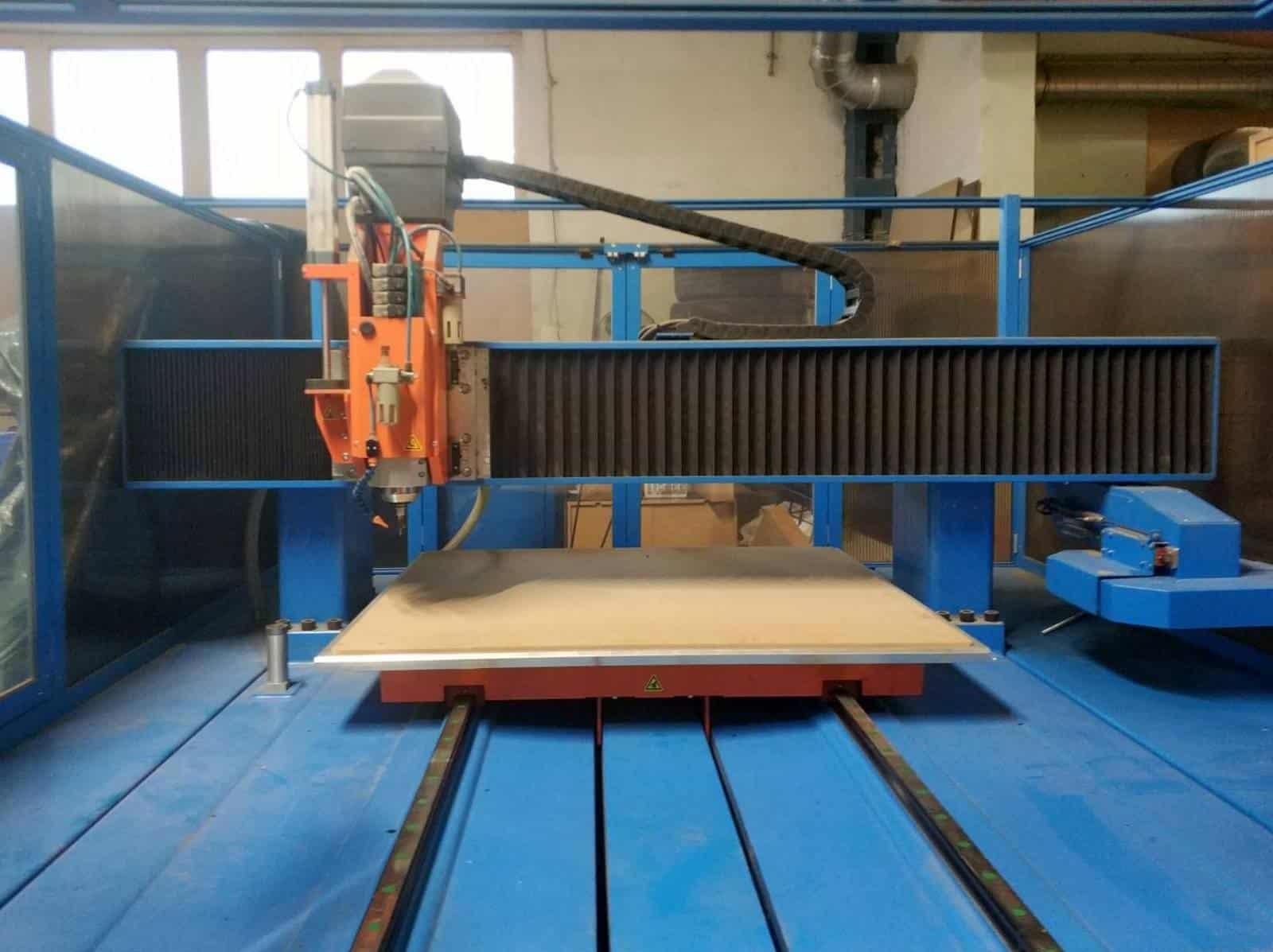

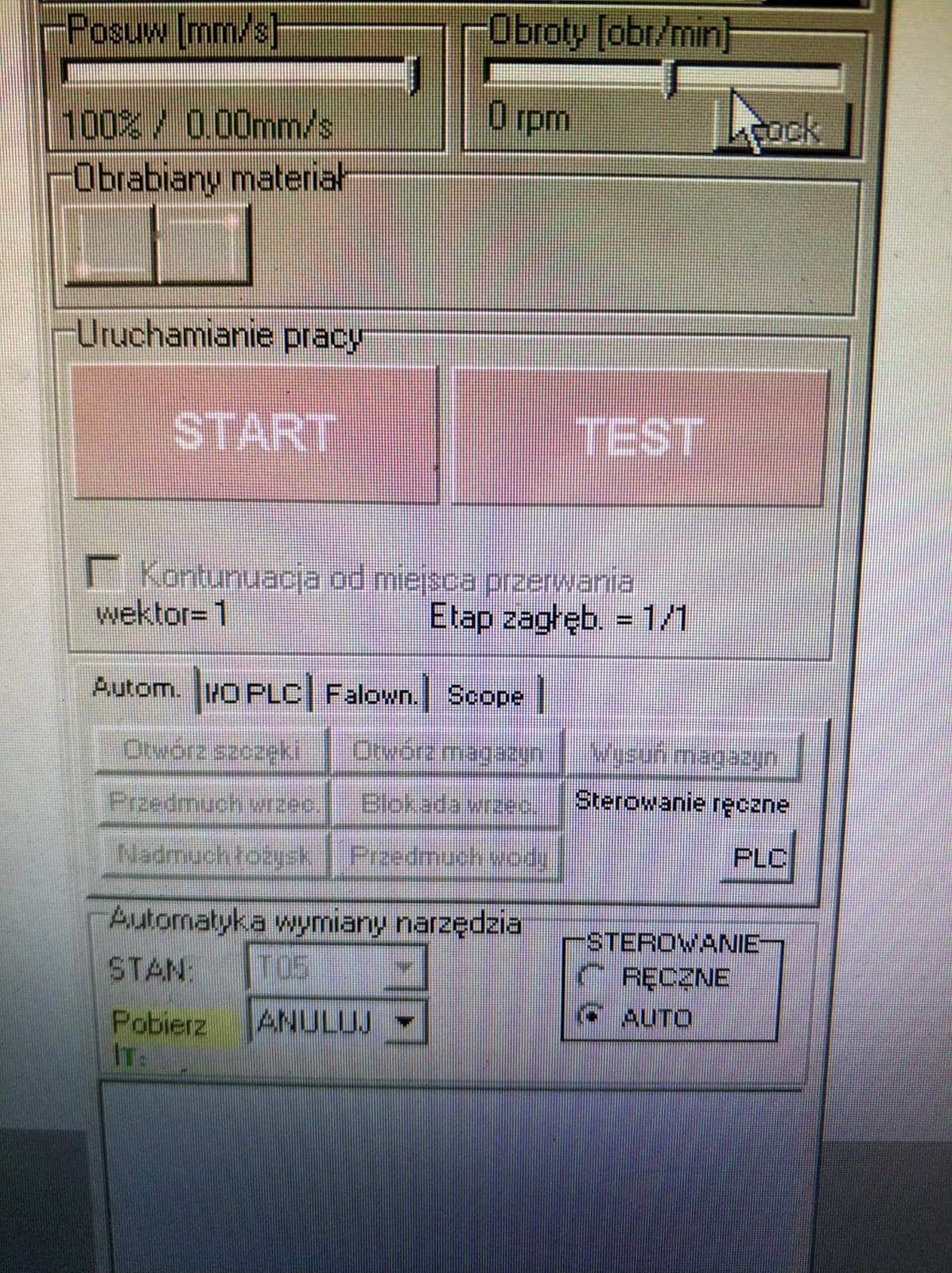

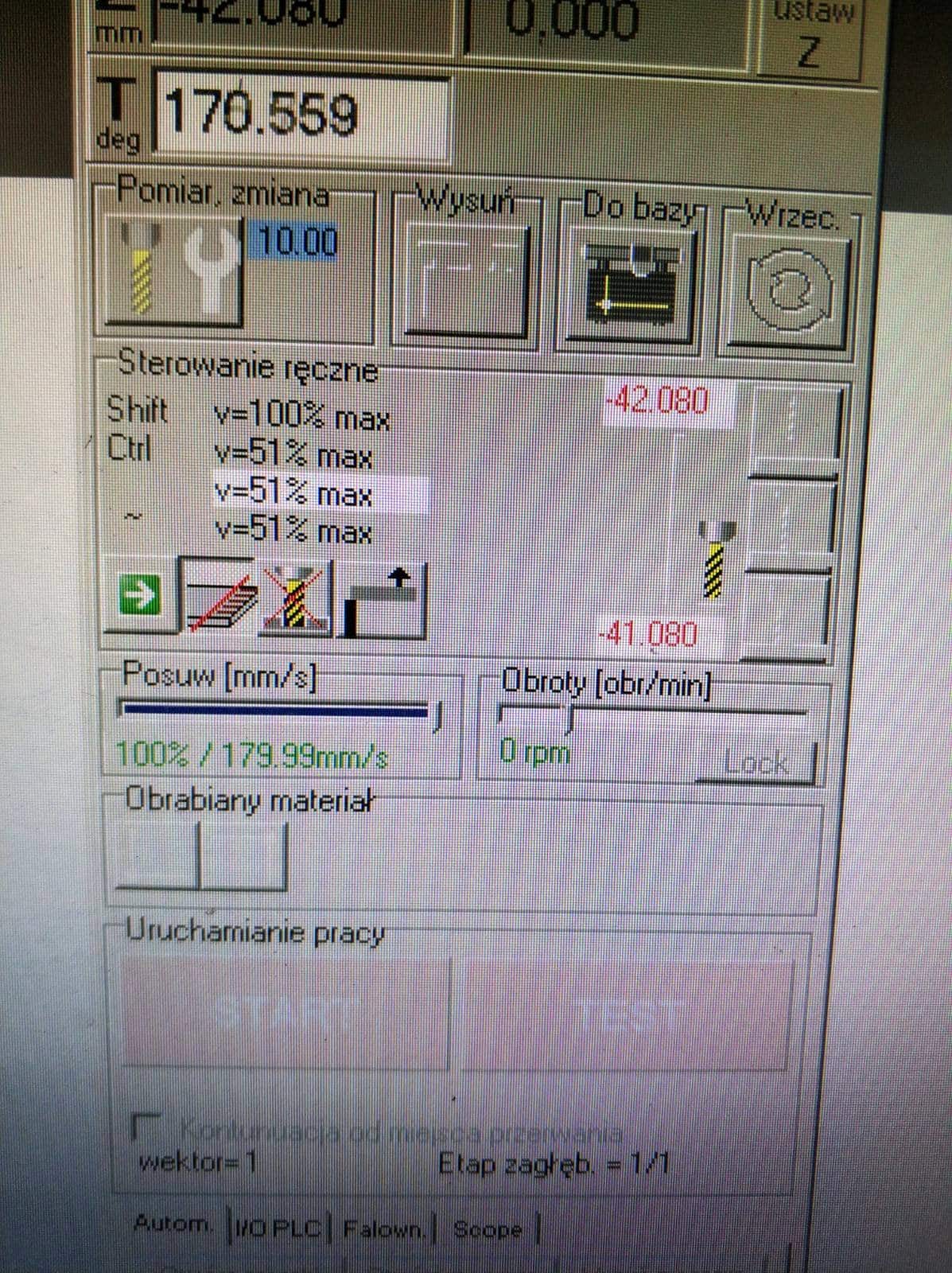

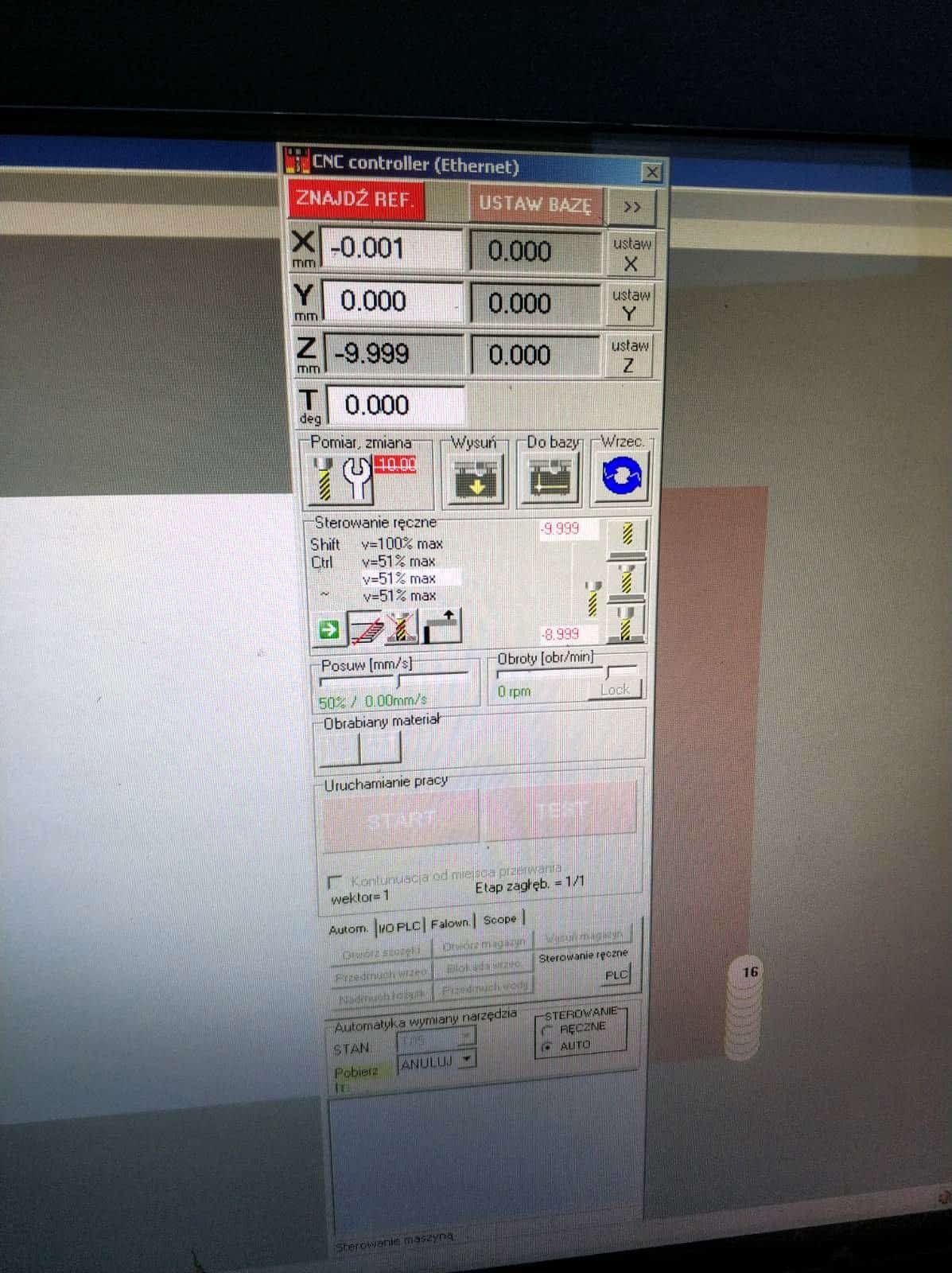

KIMLA BFN 1110 CNC machining centre was built in Poland in 2013. The machine uses shank cutters, engraving cutters or drills to manufacture, among others, injection moulds, dies or punches made of steel or aluminium. The milling machine’s servo-driven axes, together with a spindle rotating at a maximum speed of 18000 rpm, guarantee an extremely efficient, fast and accurate process for milling workpieces in a work area with feeds of 1100 mm (X axis), 1000 mm (Y axis) and 500 mm (Z axis).

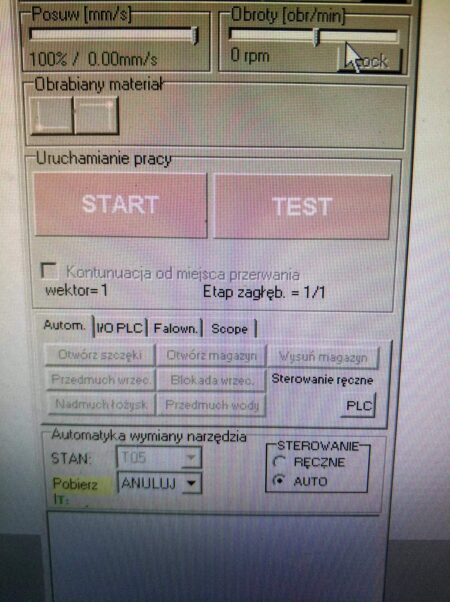

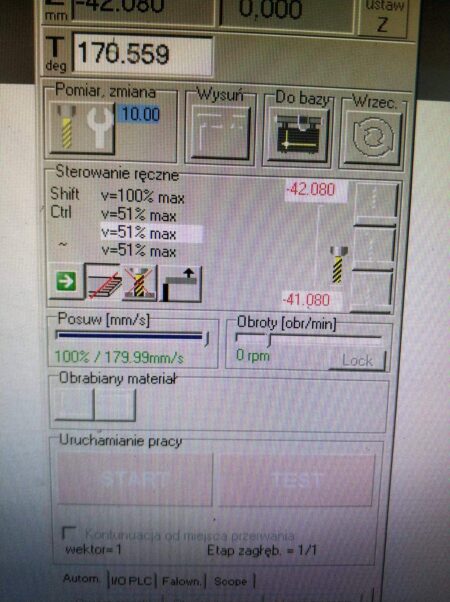

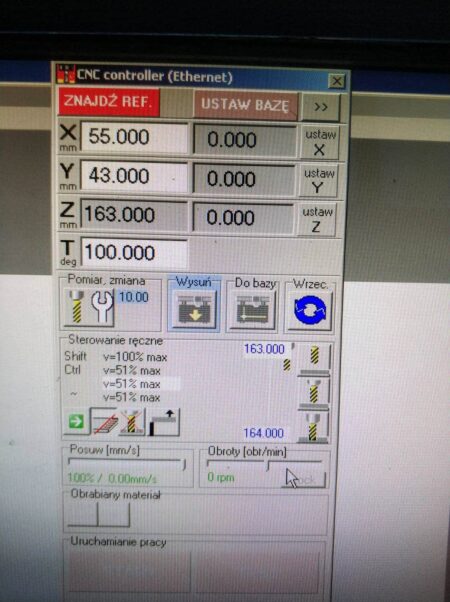

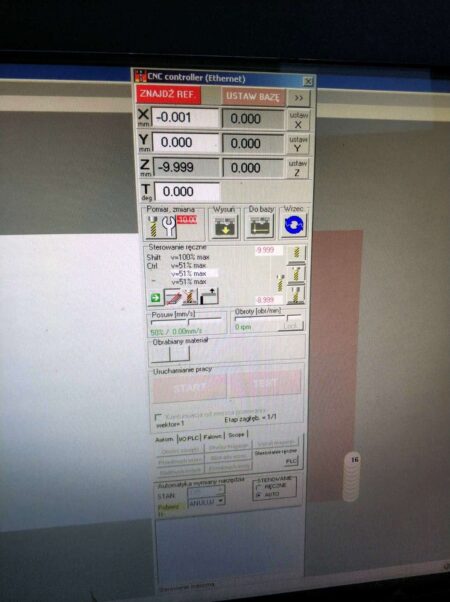

The tools used in machining are oil mist cooled to extend their service life, and the extremely useful tool length correction function prevents errors associated with setting procedures. The CNC milling plotter has extensive equipment consisting of, among others, a KIMLA CNC controller, CAD/CAM software with NESTING function and a BECKER vacuum pump. The total weight of the milling and engraving machine is 2 tonnes.

Technical data of the KIMLA BFN 1110 CNC milling machine

- feed rates in the X/Y/Z axis: 1100/1000/500 mm

- rapid traverse in the X/Y/Z axis: 180 mm/s

- minimum spindle speed: 10000 rpm

- maximum spindle speed: 18000 rpm

- positioning accuracy: 0.001 mm

- tool magazine capacity: 16 pcs.

- power: 7 kW

- power supply: 400 V; 50 Hz

- pressure: 8 bar

- transport dimensions (L x W x H): 2400 x 2350 x 2400 mm

- total weight of the BFN 1110 machine: 2000 kg

Equipment of the CNC gantry milling machine

- CNC control: KIMLA

- CAD/CAM software with NESTING function

- vacuum pump: BECKER

- axis servo motors

- oil mist cooling

- automatic tool length correction system

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe