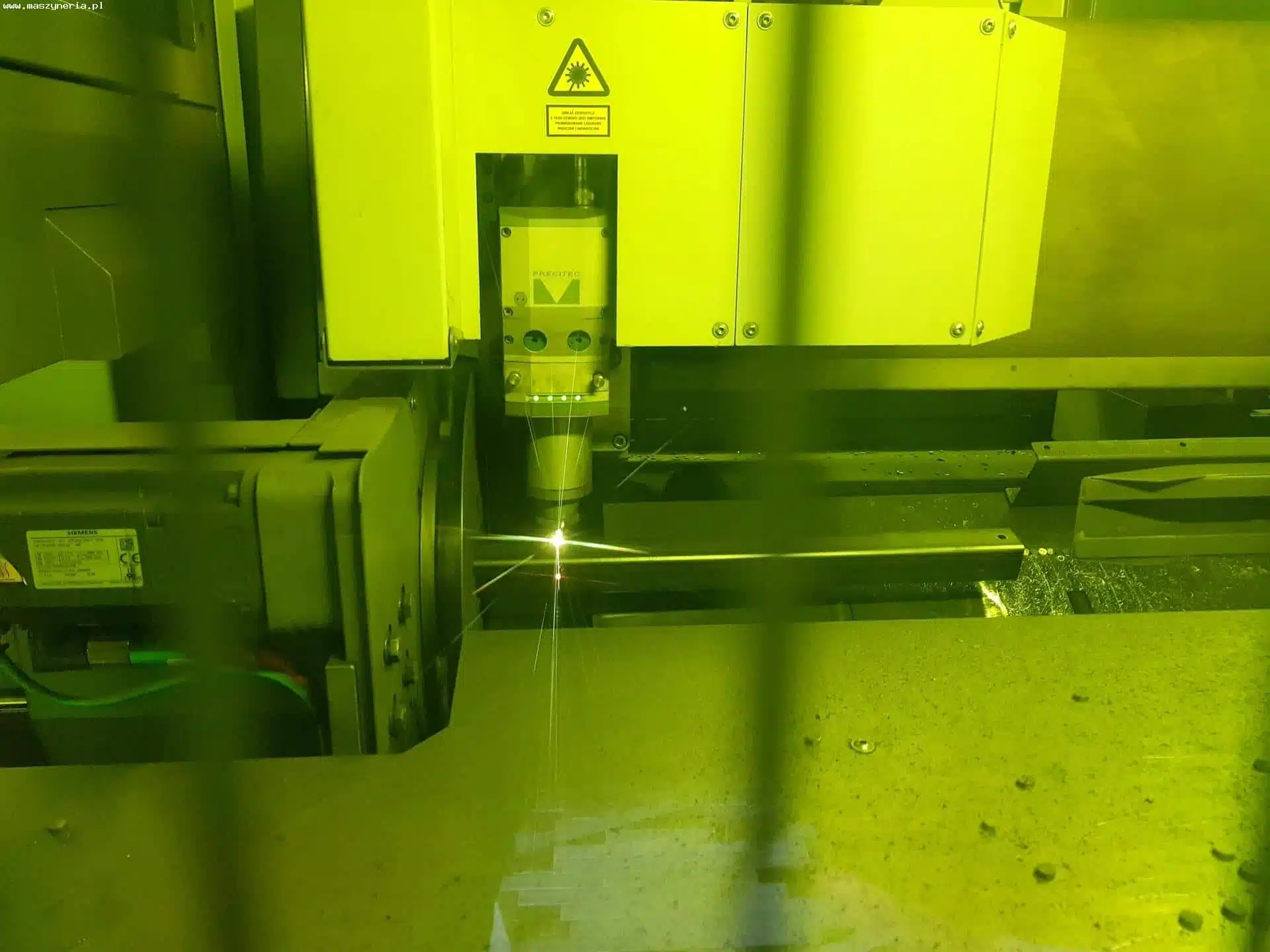

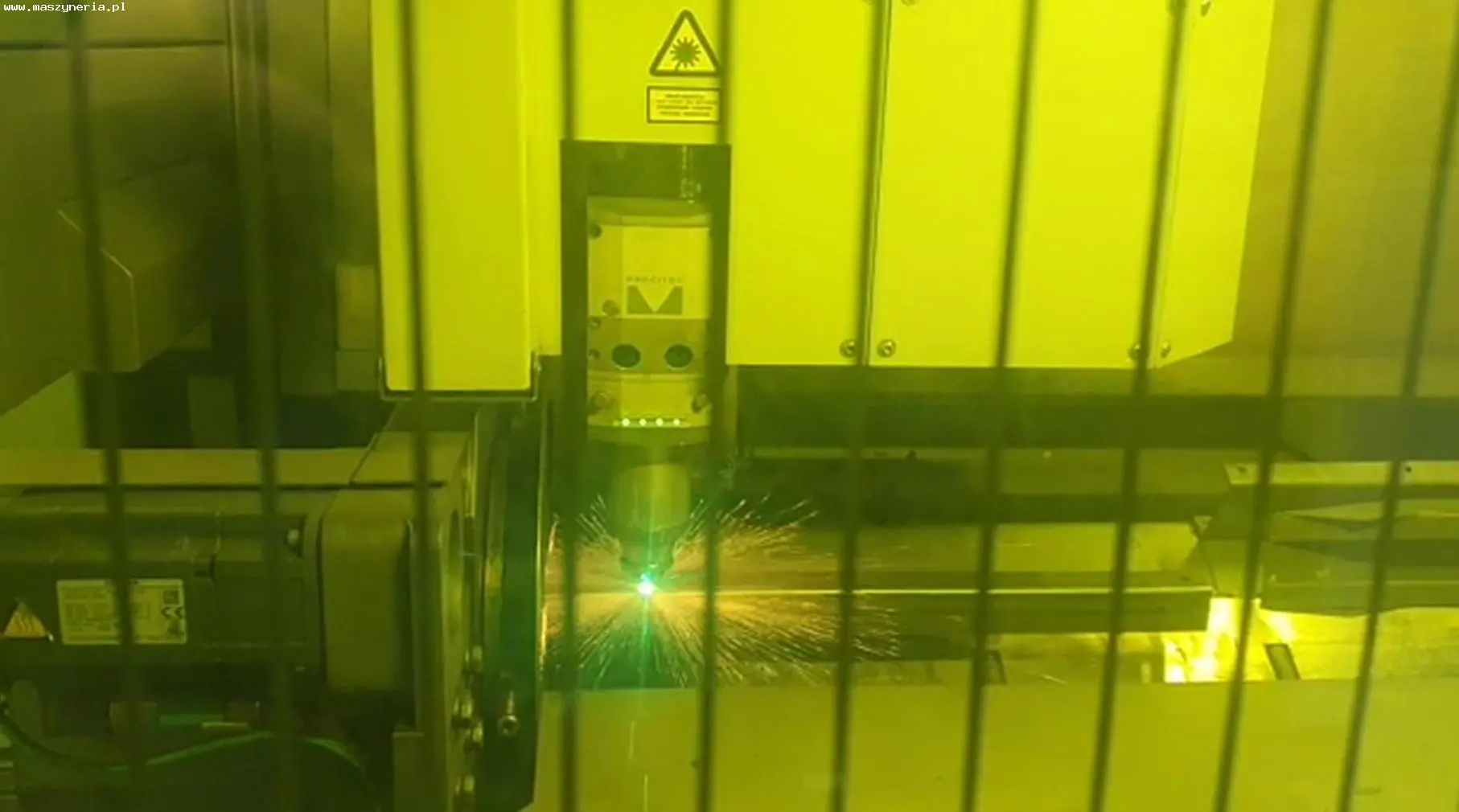

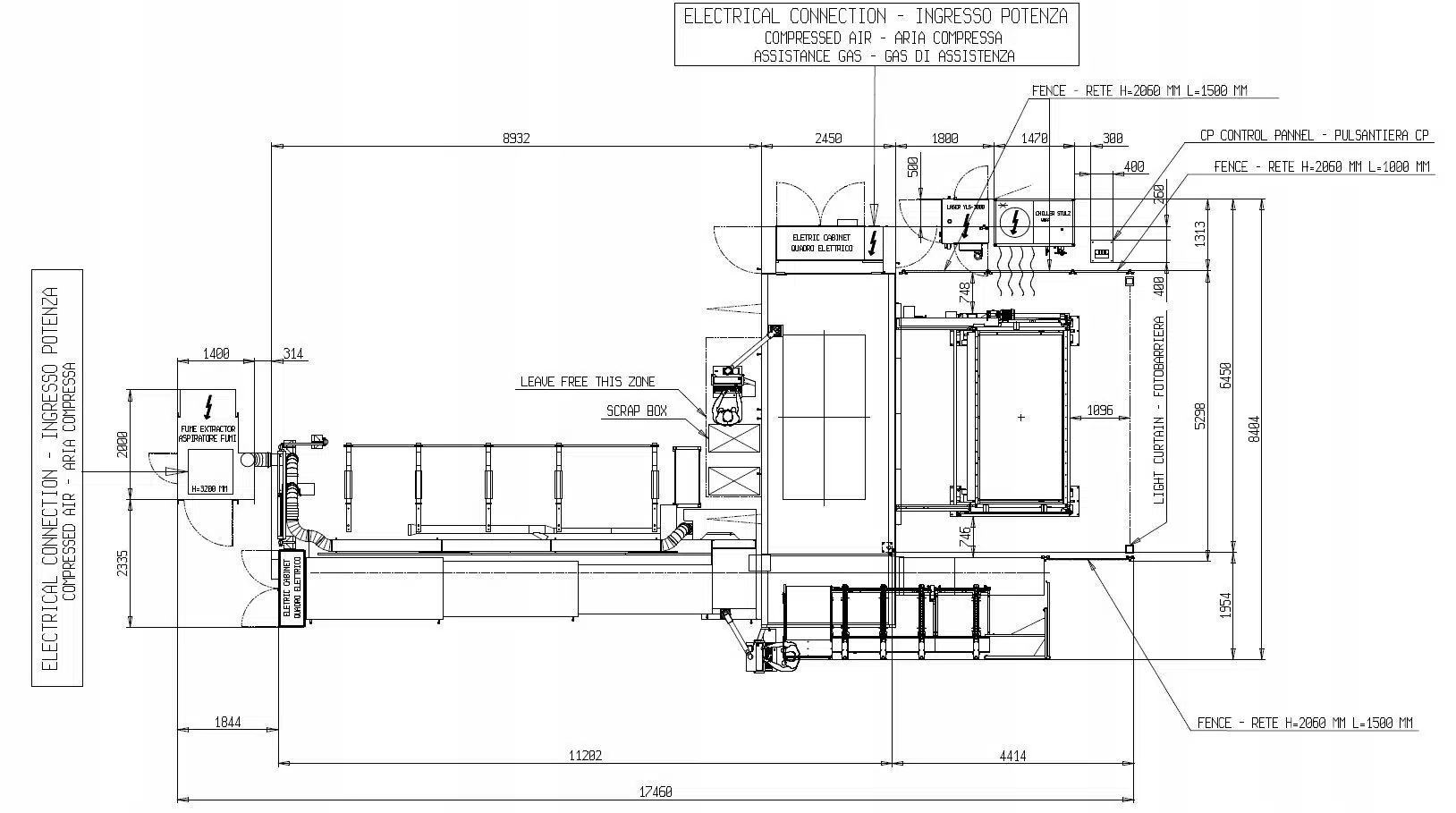

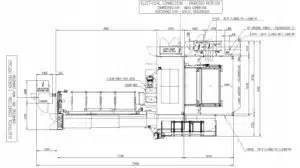

Laser COMBO BLM LC5 FIBER for cutting pipes, sheets and profiles in Fiber 2D technology was produced in Italy in 2016 (installation of the laser cutter: 2017). The laser is equipped with a transversely replaceable table with a module for cutting profiles and pipes. It is also equipped with a profile feeder, receiving table and Precitec Procutter head. The machine uses an IPG laser source with a power of 4000 W. It enables cutting ordinary steel with a maximum thickness of 6 mm (Nitrogen) or 20 mm (Oxygen), stainless steel with a thickness of 6 mm, copper and bronze with a thickness of 6 mm and aluminum up to 15 mm thick. The laser works in an automatic cycle, therefore the operator’s task at the machine is only to load the beam of profiles onto the feeder and to collect the finished parts from the unloading table belt. The machine has a table that allows processing of a sheet metal with dimensions of 3000×1500 mm. It is possible to process pipes and closed profiles with a diameter of up to 120 mm and a length of 4500 mm. The machine is built in such a way that it optimizes the distribution of parts on one profile – after its previous measurement. The BLM LC5 laser cutter allows you to cut both pipes and sheets on one machine. It is the only solution on the market that offers double the possibilities on one machine. The laser guarantees the performance of machining functions on materials such as: steel, brass, inox, copper and aluminum. In addition, it cuts small and large formats of various materials with the highest quality and efficiency.

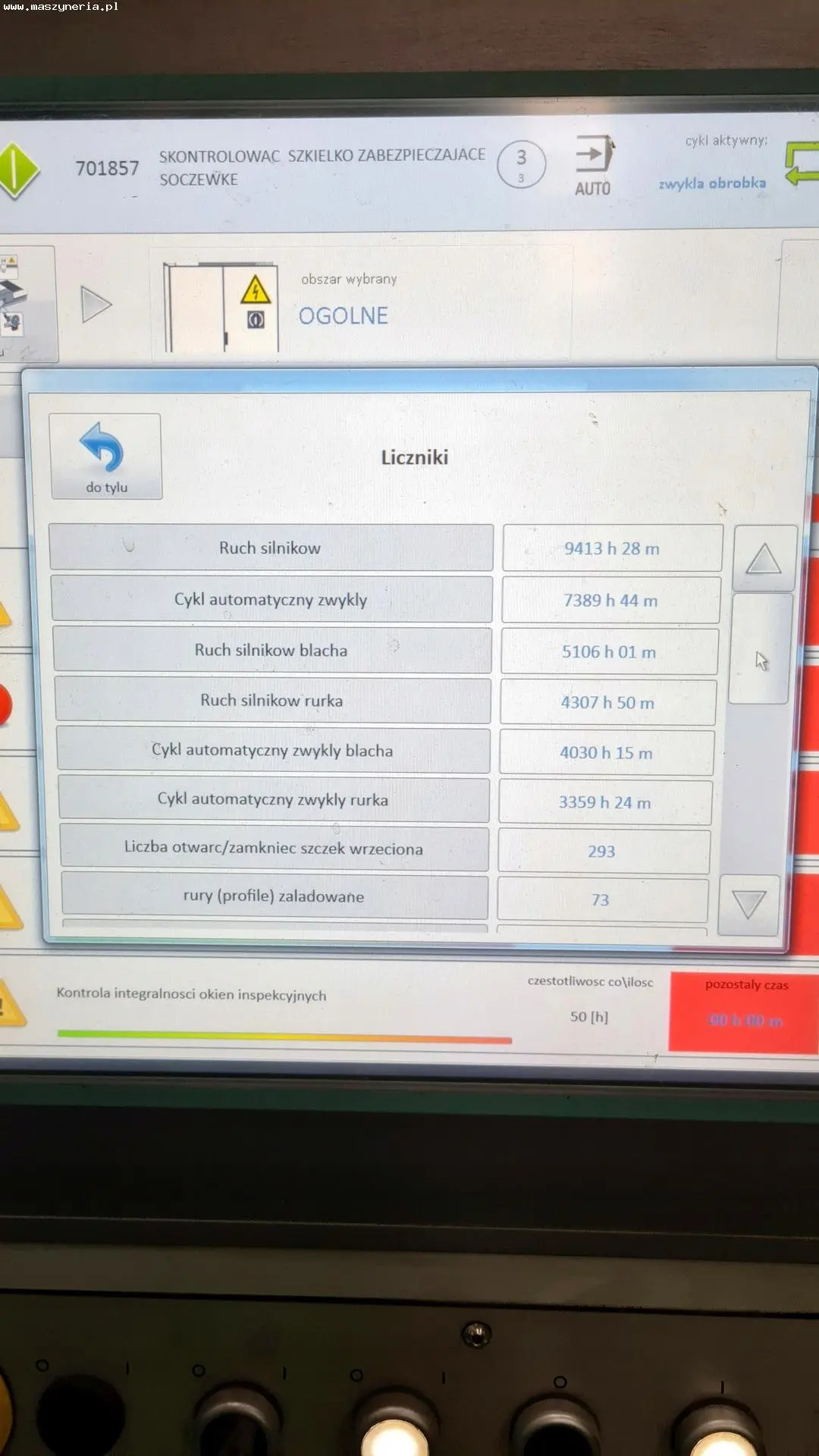

Technical data of COMBO BLM LC5 FIBER laser cutter

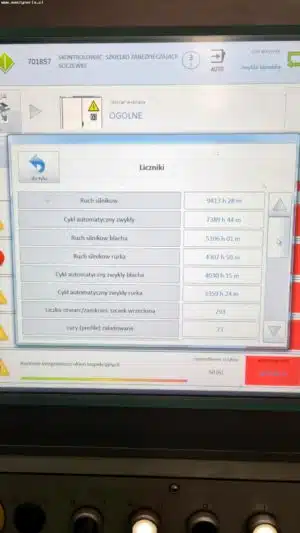

– man-hours: 9500 h

– laser source: IPG 4.0 kW, fiber optic

– Precitec Procutter head with automatic zoom

– automatic replacement of nozzles

– sheet format: 3000 x 1500 mm

– maximum cutting thickness, black steel: up to 6 mm (Nitrogen), 20 mm (Oxygen)

– maximum cutting thickness, stainless steel: up to 6 mm

– maximum cutting thickness, aluminum: up to 15 mm

– maximum cutting thickness, copper, bronze: up to 6 mm

– processing of pipes and closed profiles: up to fi 120 mm

– automatic loading of profiles: from 6.5 m

– maximum detail length, unloading length: 4500 mm

– in-line or crosswise pallet change

– seam detection

Components of the BLM LC5 machine

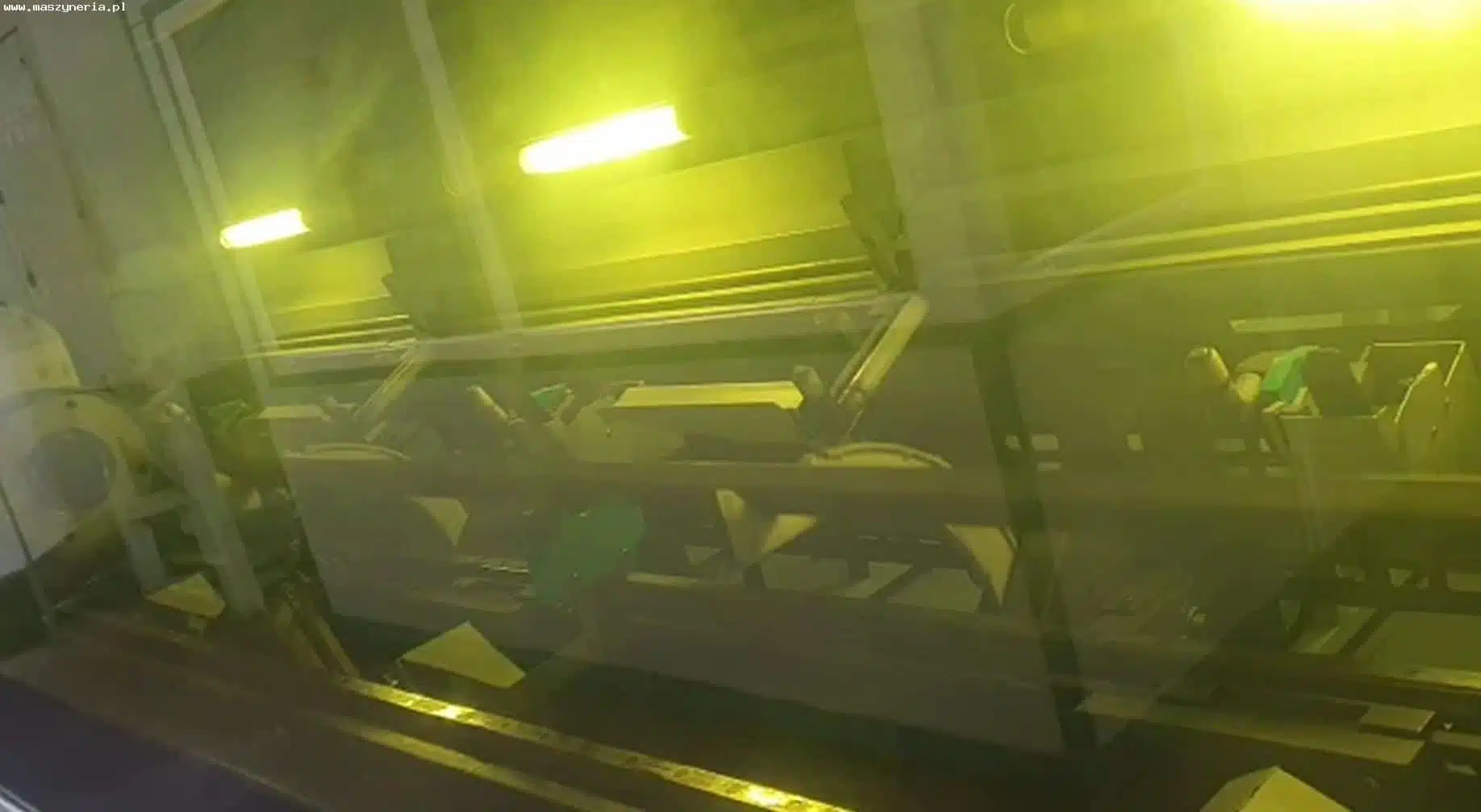

– sheet metal module

– pipe module

– IPG resonator

– refrigerator

– extraction

– automatic lime dispenser for cutting aluminum

Laser COMBO BLM LC 5 FIBER for sheets, pipes and profiles includes licenses for programs that enable creating nests and valuation of Lantek sheet metal cutting. Additionally, it has a license for the program for creating machining projects for cutting pipes and Artube profiles (with the possibility of importing element designs in STP IGS formats, etc.). The COMBO BLM LC5 FIBER laser enables a quick transition of processing from sheet to tube and vice versa, without the need to reconfigure or rearm the machine – thanks to which we achieve high production speed and improve our investments. The machine has a double plane with automatic pallet change, and also gives the possibility of manual pallet change on a single plane for the production of special products.