LVD ELECTRA FL-3015 fiber laser built in 2013. The machine has a new 3 kW source under warranty (source replacement from 2 kW to 3 kW). A new optical fiber from the head to the laser is installed with the source (it is under warranty).

Technical parameters of the FIBER LVD ELECTRA FL-3015 laser

– laser source power: 3 kW

– HighLight Compact Fiber Laser FL3000C laser source; Fiber (year of production 2019, 2h worked)

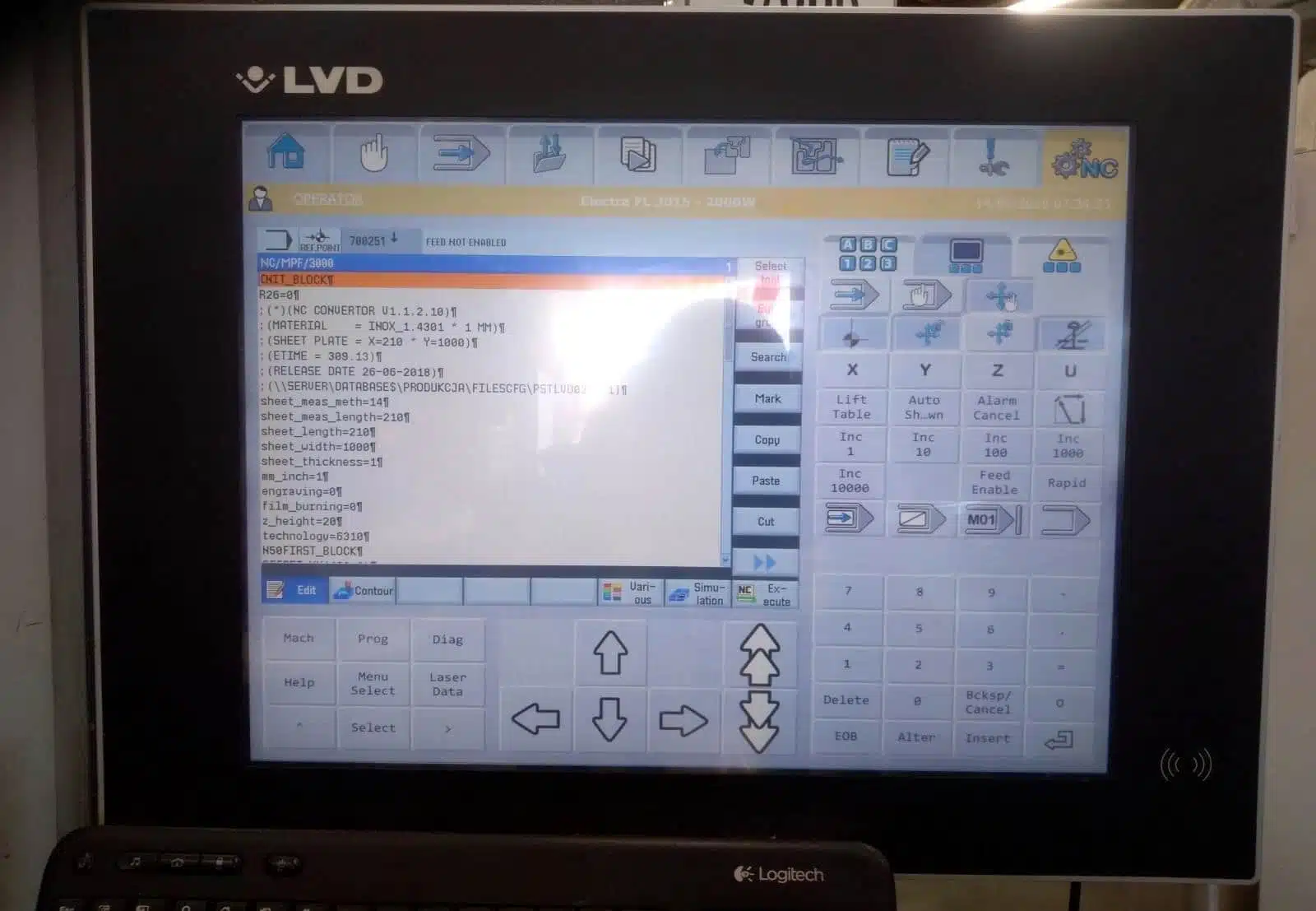

– CNC control system: Siemens SINUMERIK 840 Dsl SINAMICS S120, controller equipped with a 19-inch touch screen, with an intuitive Touch-L interface

– cutting surface: 3000 x 1500 mm

– X, Y, Z axis movement range: 3080 x 1555 x 100 mm

– rapid feed speed: 170 m / min.

– maximum thickness of the material to be cut: ST3: 10 mm, INOX: 8 mm, PA11: 6 mm

– overall dimensions including the system of loading tables, cooler, source and light curtains, length x width x height: 11000 x 6000 x 2250 mm

– total weight of the machine: 15,000 kg

Advantages of the FIBER LVD ELECTRA FL-3015 fiber laser cutter

– closed cooling circuit is flooded with Glycol (for Fiber source, electrical cabinets, head and drives)

– it is equipped with a system of sliding tables, allowing for quick loading and unloading of sheet metal during cutting

– has one head with a lens ”

– Precitec HP SSL cutting head has an anti-shock system and an obstacle detector

– it is equipped with a non-contact capacitive sensor measuring the distance between the nozzle and the sheet metal, used in the system of maintaining a constant distance between the nozzle and the material (in case of deformation of the material surface)

– laser eye: very fast, contactless and accurate determination of the position of the sheet, located on the table

– photo-electric protection of the loading / unloading area (area protected by a photoelectric barrier system)

– automatic change of cutting gases: nitrogen, oxygen, air

– automatic setting of the beam focus (FD)

– the machine meets EU standards, in accordance with the requirements of the CE mark