The MAKA AR 37 5-AXIS machining center was manufactured in Germany in 2001. It is used for the processing of aluminum and PVC profiles. The milling center has 5 axes and BWO CNC 900C numerical control, which ensures easy operation of the machine. The machine has a magazine that can accommodate 20 tools.

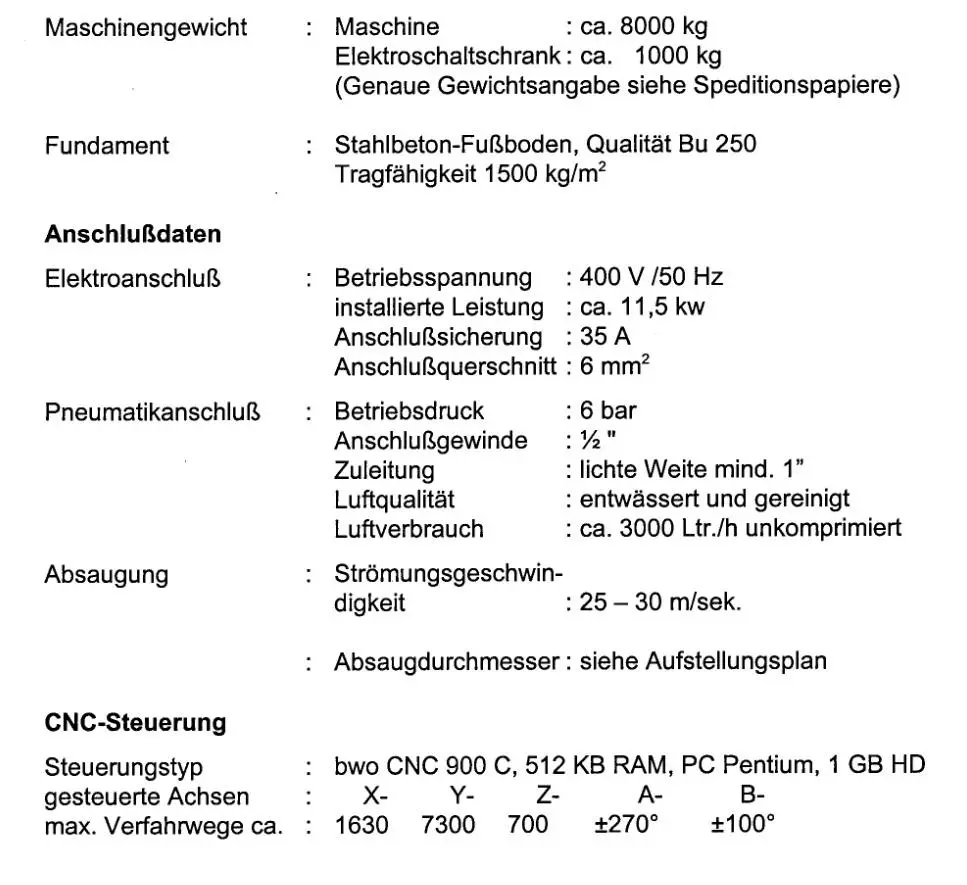

Technical data of the MAKA AR 37 CNC milling machine

– CNC control: BWO CNC 900C (512 KB RAM, PC Pentium, 1 GB HD)

– 5 axes (controlled axes: X, Y, Z, A, B)

– maximum control possibilities: X axis: 1630, Y axis: 7300, Z axis: 700, A axis: + -270 degrees, B axis: + -100 degrees

– maximum table length: 9 m

– maximum size of the processed detail: X axis: 500 mm, Y axis: 7300 mm, Z axis: 280 mm

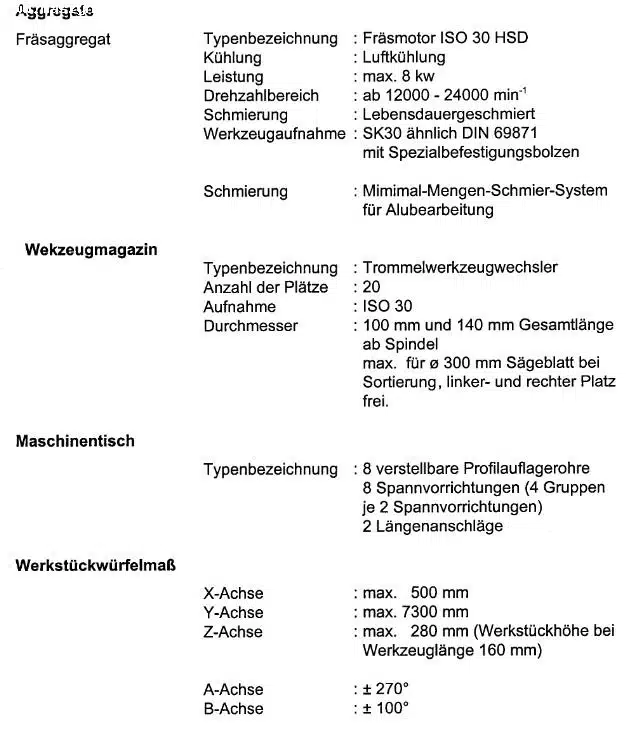

– number of tools in the magazine: 20

– mounting: ISO 30

– tool diameter: 100 mm

– tool length: 140 mm

– working pressure: 6 bar

– installed power: approx. 11.5 kW

– operating voltage: 400 V / 50 Hz

– connection fuse: 35 A

– weight: 9 t (machine: 8 t, electric cabinet: 1 t)

– tool magazine

– machine documentation

Equipment of the MAKA AR 37 milling center

– computer control: BWO CNC 900C

– 5 axes – controlled axes: X, Y, Z, A, B

– tool magazine

– Technical Documentation