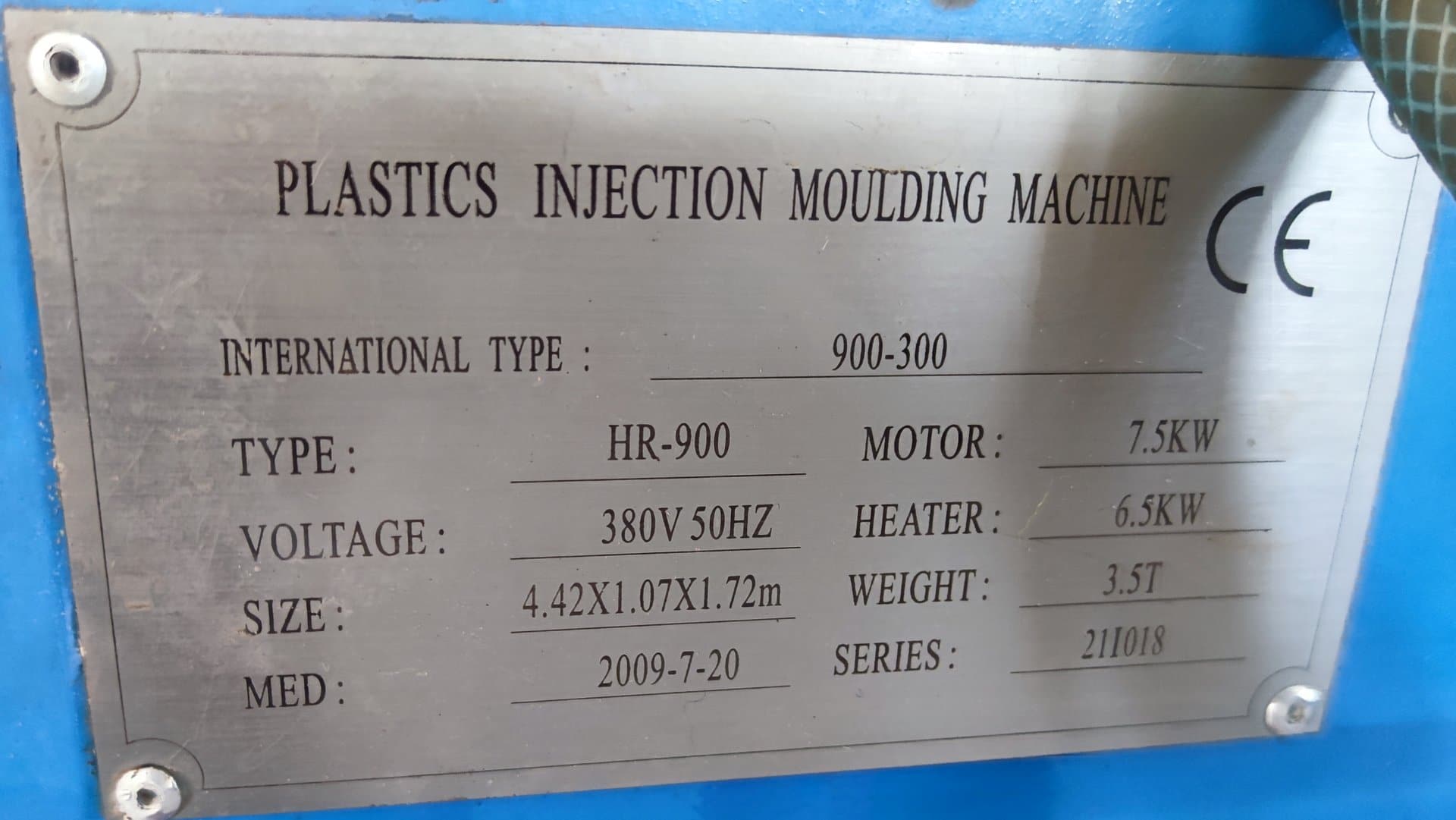

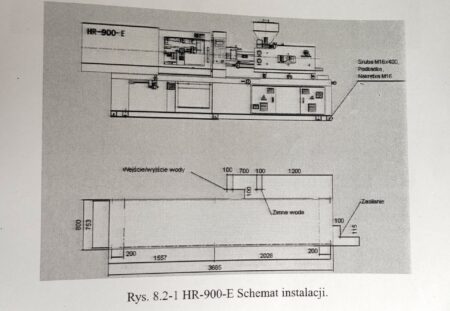

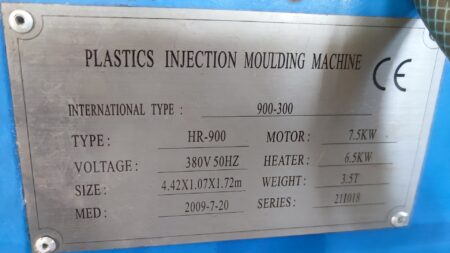

PONAR ŻYWIEC HR-900 injection moulding machine built in 2009 in Poland, is used for injection moulding of plastics. The machine works with injection moulds with a height from 130 to 380 mm, clamping at a force of 90 tons. The structure and all components of the machine have been designed to guarantee the best working efficiency and the highest quality of the produced parts.

The plastic injection moulding machine is equipped with a modern and easy to use CNC control Powertech PP 250, allowing full control of the machine by the operator. The installed screw with a diameter of 30 mm, rotates at a maximum speed of 250 rpm. The total weight of the HR-900 injection moulding machine is 3500 kg.

PONAR ŻYWIEC HR-900 injection moulding machine characteristics

- CNC controller: Powertech PP 250

- mould clamping force: 90 t (900 kN)

- minimum mould height: 130 mm

- maximum mould height: 380 mm

- injection volume: 117 cm3

- injection weight: 106 g

- injection pressure: 252 MPa

- injection capacity: 67 g/s

- diameter of installed screw: 30 mm

- maximum screw speed: 250 rpm

- plasticisation capacity: 9.2 g/s

- nozzle stroke: 220 mm

- mould opening stroke: 310 mm

- distance between columns: 360 x 360 mm

- number of ejectors: 5+2 pcs

- ejector stroke: 100 mm

- ejection force: 34 kN

- hydraulic system oil pressure: 17.5 MPa

- tank capacity: 180 l

- engine power : 7,5 kW

- power supply: 380 V; 50 Hz

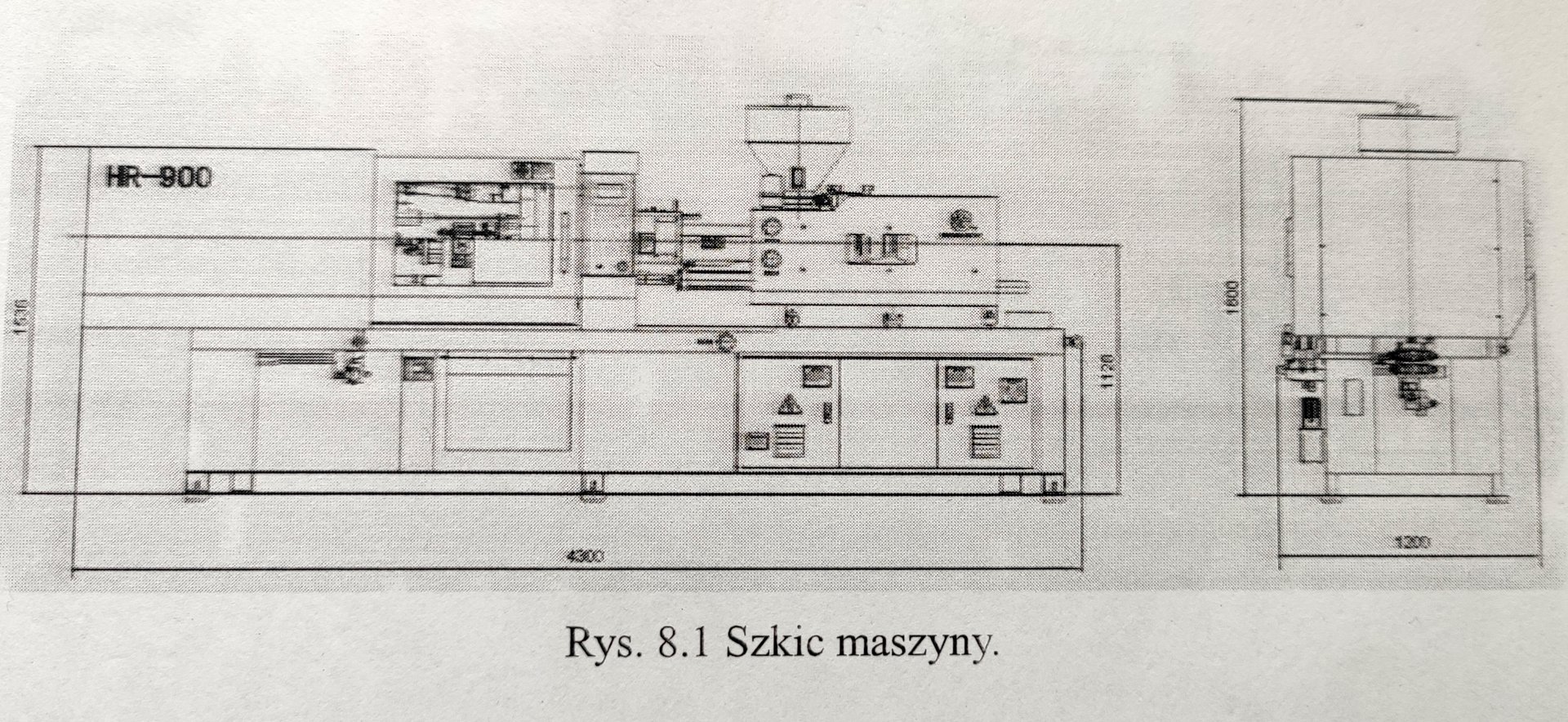

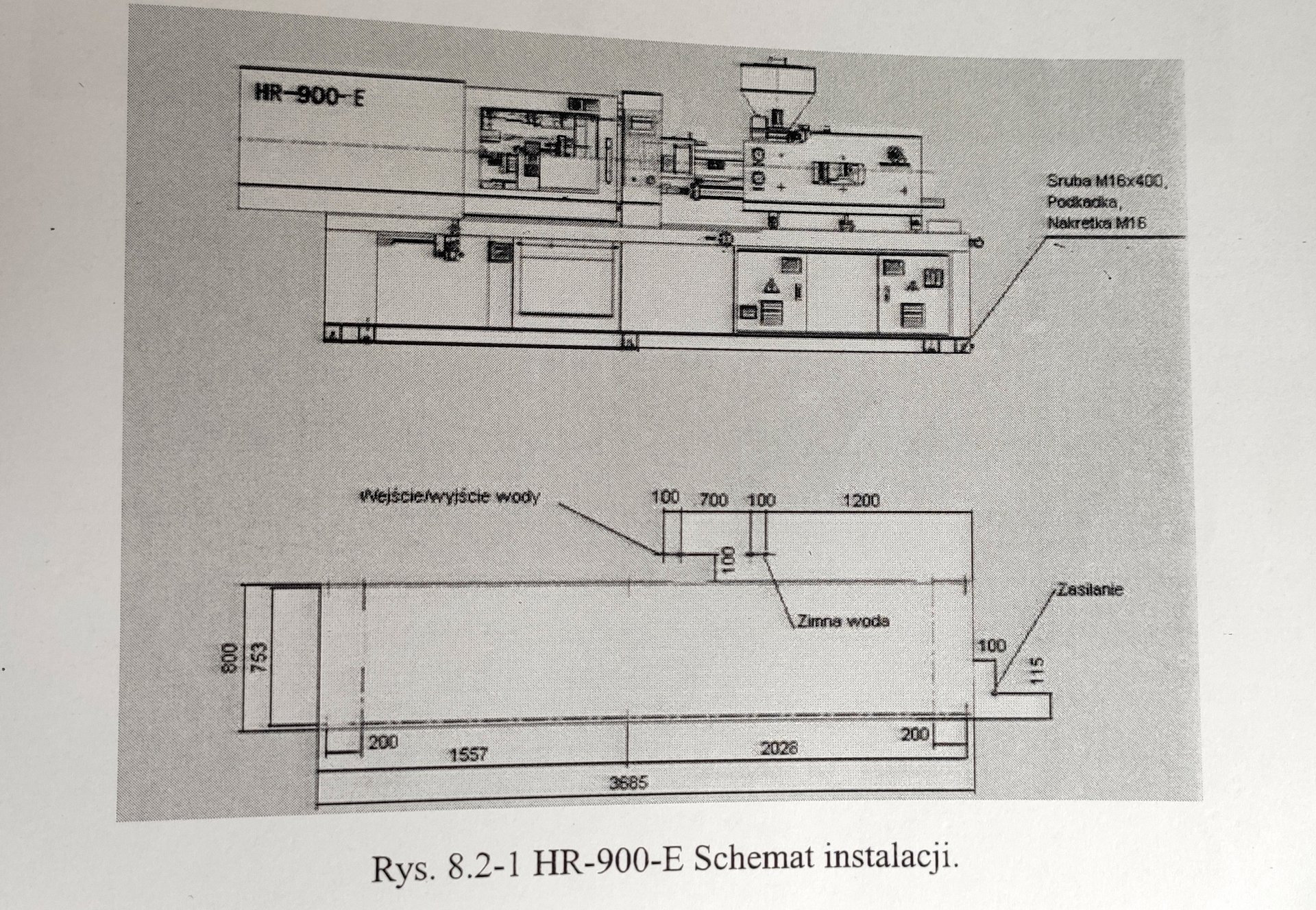

- dimensions (L x W x H): 4.3 x 1.2 x 1.8 m

- total weight of machine 3500 kg

Equipment of the injection moulding machine

- option – cores (2 pcs.)

- air valve (2 pcs.)

- pads (6 pcs.)

- clamps for mould fixing (8 pcs.)

- plastic feeder

- central oil lubrication

- DTR – technical and operation documentation

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe