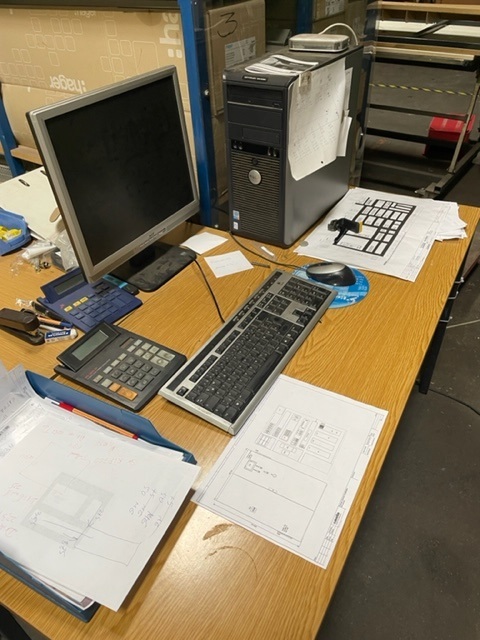

RITTAL PERFOREX BC 2001 S drilling and milling center was built in 2004 in Germany by Rittal GmbH & Co. KG. The machine is used for the fully automatic machining of electrical enclosures made of steel, aluminium or plastic. Threads in the range of M3 to M8 and holes in the range of 3 mm to 10 mm are produced on mounting plates with a maximum thickness of 5 mm by means of a movable workhead. The work table, inclined at 15°, facilitates chip removal as well as increases operator comfort. The technical solutions used significantly reduce the production time of electrical cabinets to just 15-20 minutes. The PERFOREX BC 2001S electrical cabinet machining center on offer is equipped with, among others, an advanced CNC controller, compressor and tools. The total weight of the machine is 2200 kg.

Technical specifications of the RITTAL PERFOREX BC 2001 S electrical enclosure machining center

- number of axes: 4

- maximum electrical enclosure dimensions (L x W): 2200 x 1200 mm

- maximum plate thickness: 5 mm

- hole diameter range: 3-10 mm

- thread range: M3-M8

- work table angle: 15°

- machine dimensions (L x W x H): 4150 x 1700 x 2450 mm

- machine dimensions with side guards (L x W x H): 4150 x 2850 x 2450 mm

- control panel dimensions (L x W x H): 1050 x 600 x 2080 mm

- weight of the RITTAL PERFOREX BC 2001 S machine: 2200 kg

Equipment of the RITTAL drilling center

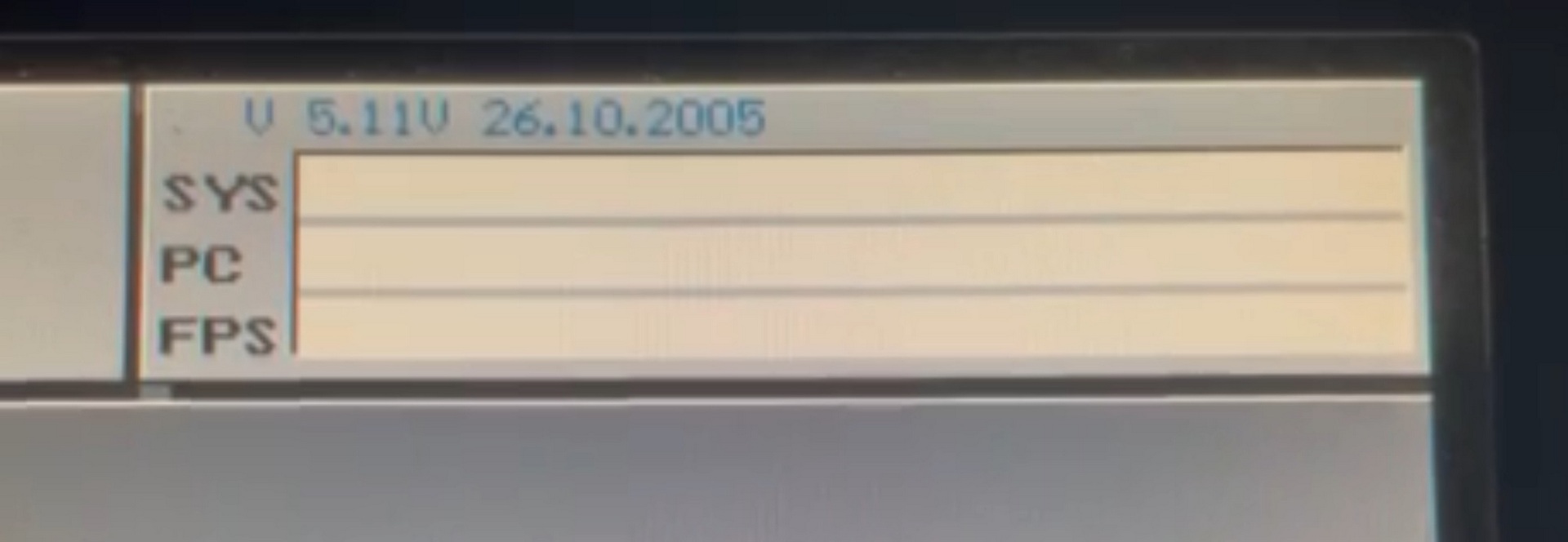

- CNC control

- tool holder with drill bits for diameters 2 mm; 2,5 mm; 3,3 mm; 4,2 mm; 5,1 mm; 6 mm; 6,8 mm; 8,5 mm

- tool holder with threader for threads M4; M5; M6; M8; M10

- light curtains

- computer with software

- compressor with tank and hose

- pneumatic pistol with hose (2 pcs.)

- lubricator

- side guards

- workspace illumination

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe