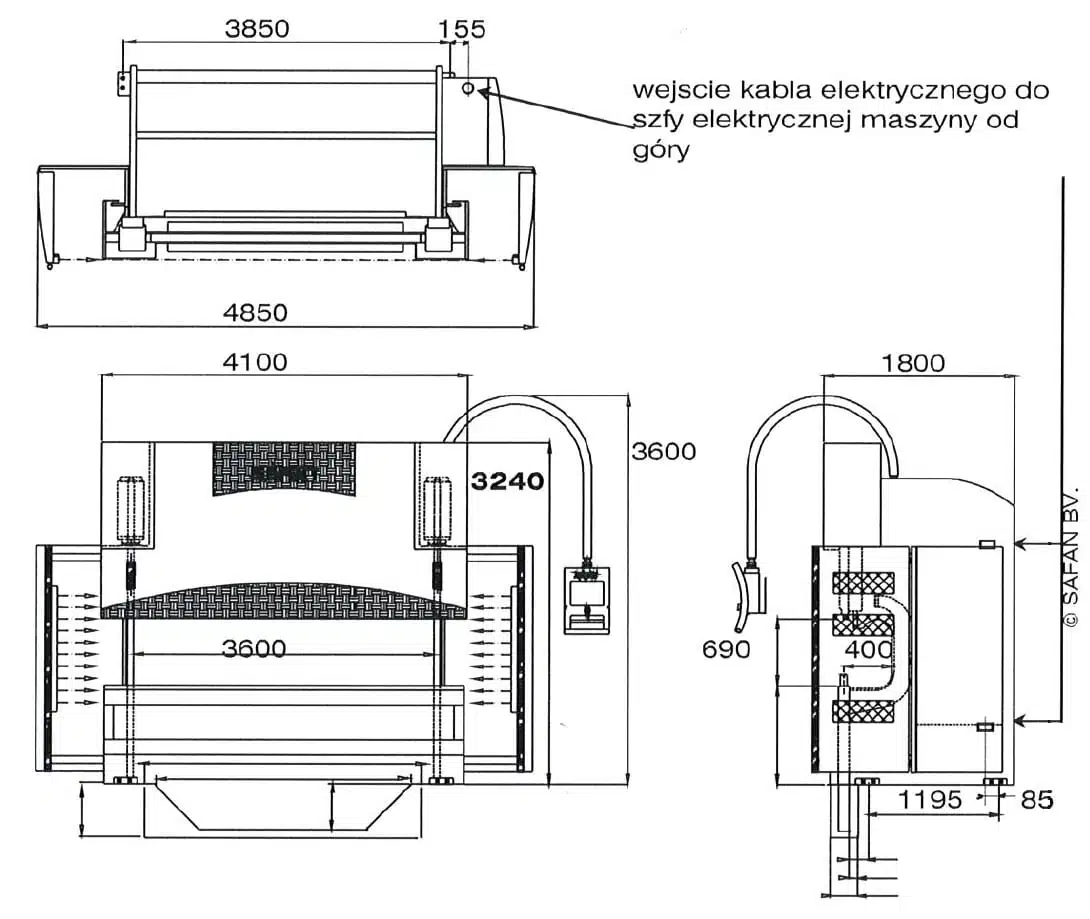

The Safan H-Brake 170-4100 TS 1 press brake was manufactured in 2005 in the Netherlands. This press is optionally equipped with a safety system with a light curtain. In addition, it is equipped with systems that facilitate and accelerate work, such as hydraulic clamping of the upper tool NSCL I + 80mm and CNC controlled Crowning – CVB / D T5 deflection arrow compensation. The rear bumper has the X, R, Z1 and Z2 axes independently programmable. On the front of the Safan H-Brake 170-4100 press brake are movable aluminum rules. All backgauge axes and deflection arrow compensation can be easily programmed via the CNC control. In order to ensure high rigidity of the machine, the lower beam is recessed below the floor level.

Technical parameters of the Safan H-Brake 170-4100 TS 1 press brake

– number of controlled axes: 6 + Crowning (Y1, Y2, X, R, Z1 and Z2)

– maximum pressure: 170 tons (1700 kN)

– maximum bending length: 4100 mm

– top beam travel speed: 200mm / s

– bending speed: 10 mm / s

– return speed: 120 mm / s

– dimension Q: 690 mm

– projection 400 mm

– distance between the body walls: 3600 mm

– maximum stroke: 300 mm

– maximum stroke of the bumper: 600 mm

– main engine power: 11 kW (15 HP)

– engine speed: 1440 rpm

– pump: Voith (IPV 4 / 20-171 31l / min)

– oil tank capacity: 200 l

– maximum working pressure: 345 bar

– minimum operating pressure: 200 bar

– upper position pressure: 180 bar

– maximum height of the machine: 3240 mm

– maximum height with the CNC arm: 3600 mm

– transport height: 2900 mm

– top beam length: 4100 mm

– total length of the machine with covers and curtains: 4850 mm

– width (front to back): 1800 mm

– net weight: 15700 kg

– supply voltage: 3x400V / 50 / 60Hz / N / PE

– cross-section of the power cord: 4m2

– maximum connected power: 11 kW

Additional equipment for the Safan H-Brake 170-4100 TS 1 press brake

– CNC control

– increased stroke by 100mm: 300mm

– security system with a programmable light curtain

– hydraulic upper tool clamping: NSCL I + 80mm

– die clamping: mechanical clamp

– deflection arrow compensation: CNC controlled crowning

– CNC controlled rear bumper axes: X, R, Z1 and Z2

– movable, aluminum rules at the front of the machine