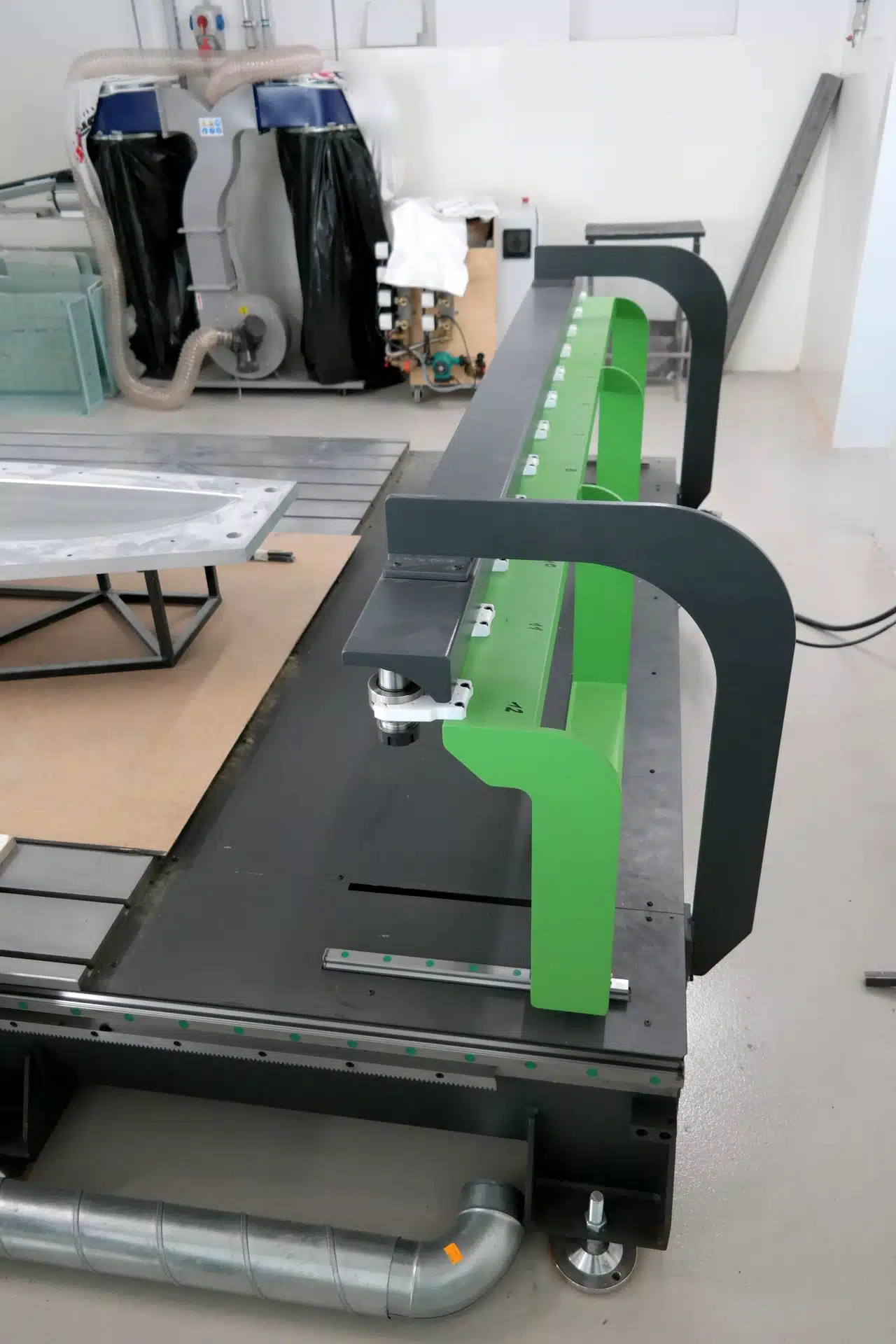

The SERON 2131 PROFESSIONAL CNC milling plotter was produced in 2019 in Poland. The machine is dedicated to the processing of materials such as: soft and non-ferrous metals, i.e. copper, brass, bronze, aluminum, but also composites such as dibond, alucobond, etc., plastics: PVC, plexiglass, polycarbonate, rubber, polyamides, Teflon, etc., engraving laminates, extruded materials, foams, etc., solid wood, chipboards, plywood, MDF, OSB. The plotter has a steel welded body and easy-to-use control, thanks to which it will meet the expectations of even very demanding customers. The SERON 2131 PRO milling plotter allows you to process difficult materials with the use of a powerful spindle and tools with large diameters. When machining, the ground clearance can be increased up to 1000 mm. Optional attachments such as drilling heads and swivel spindles (+/- 100 degrees) can also be used on this machine.

Technical data of the SERON 2131 PRO CNC milling machine

– CNC control: OSAI, 4 axes

– working area: 2100 x 3100 mm

– Z axis range: 600 mm – PRO

– AC High Speed servo drive (complete set with planetary gears)

– T-slot table for fixings: M10 (made of solid steel): 6.51 M2

– manual manipulator (option for NK260, NK300, MACH3MILL, OSAI)

– electrospindle: HITECO 10 kW (max. 12 kW) – ATC, up to 24,000 rpm.

– fan cooling

– tool mounting: HSk63 holder

– lion magazine: 12 positions (from model 1310)

– precise tool sensor: 2 pcs.

– cooling mist: automatic control

– active oscillating knife: pneumatic (MACH3MILL OSAI 4-axis or NK300 control with ZW3D software required)

– automatic central lubrication with grease

– tilting electrospindle in the range: from -95 degrees to +95 degrees

– HSK-F63 (ER32) holder: 12 pcs.

– ER32 collet for the CNC router SERON 2131 PRO: 12 pcs.

– dimensions of the machine: approx.3.5 x 2.5 x 3 m

– weight: approx. 7 t