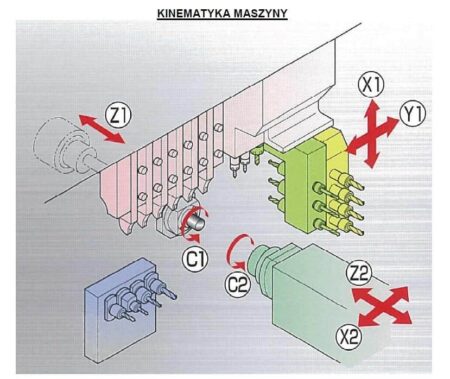

STAR SB-20R type G CNC turning centre was manufactured in 2014 in Japan. The machine is distinguished from other machines of its type by its compact size and a range of features that allow it to perform virtually any type of machining on workpieces with a maximum diameter of 20 mm. The maximally durable and rigid design additionally ensures the incredible stability and rigidity of the process, required to achieve excellent turning precision and quality.

Inside the large working area there are two spindles (main spindle and sub-spindle) with C-axis, which are driven by reliable high-power motors. The sub-spindle, in combination with the driven tools, allows completely independent machining after capture. The lathe also features a revolutionary guide sleeve change system, which allows the machine to switch between guide sleeve and no guide sleeve mode.

The STAR SB20R type G Swiss-type automatic lathe has so far only machined parts made of brass and is not worn out. The offer comes with extensive equipment, including an FMB turbo 2-20 / 4200 A bar feeder, a 6-station 12×12 mm knife vice and an intuitive FANUC Series 0i-TD CNC control. The CNC twin-spindle lathe weighs 1750 kg.

Technical specifications of STAR SB-20R type G CNC lathe

General data

- number of axes: 7

- axis rapid traverse: 35 m/min

- working hours: 25561 h

- machine switch-on time: 29232 h

- power consumption: 3.7 kVA

- power supply: 3x 200 V; 50/60 Hz

- dimensions (L x W x H): 2070 x 1177 x 1760 mm

- weight of bar feeder: 650 kg

- weight of machine: 1750 kg

Main spindle

- maximum turning diameter: 20 mm

- maximum rotational speed: 10000 rpm

- maximum spindle stroke: 205 mm

- number of turning tools: 6

- C axis

- drive power: 2.2/3.7 kW

Sub-spindle

- maximum turning diameter: 20 mm

- maximum drilling diameter: 8 mm

- maximum threading diameter: M6 x 1,0

- maximum rotational speed: 9000 rpm

- C axis

- drive power: 1,1 kW (0,55 kW continuous duty)

4-slot through-cutting chuck

- number of face/back machining tools: 4/4

- maximum drilling diameter: 10 mm

- maximum threading diameter: M8 x 1.25

Rotary transverse tools

- number of tools: 3

- maximum drilling diameter: 7 mm

- maximum threading diameter: M6 x 1,0

- maximum driven tool rotational speed: 6000 rpm (ER16) or 8000 rpm (ER1)

- power of driving tools: 1,0/1,2 kW

Equipment of the STAR MICRONICS Swiss-type lathe

- CNC control: FANUC Series 0i-TD

- bar feeder: FMB turbo 2-20 / 4200 A

- 6-station knife vice with 12×12 mm section

- 4-cavity sleeve holder

- back-machining attachment with 4 ER16 sleeves

- synchronous rotary collet set NEUKOMM 39.001 with overpressure blower

- F25 collet housing (main spindle and capture spindle)

- tools

- workpiece ejection sensor

- workpiece breakage sensor

- central lubrication

- bar feeder connection

- coolant tank with level and flow sensor

- pneumatic unit

- RS232C port

- technical documentation

- technical passport of the machine with a list of all maintenance and repairs

– bar diameter range: 2-20 mm

– maximum bar length: 4200 mm

– feed rate: 0-300 mm/s

– return speed: 0-600 mm/s

– knives for thread cutting holder, left (1 pc)

– inserts, left (3 pcs)

– knives for thread cutting holder, right (1 pc)

– inserts right (5 pcs)

– knives for holder for chisel (2 pcs.)

– chisel inserts (2 pcs)

– knives for turning holder (1 pc)

– turning inserts (2 pcs)

– slot inserts 1.0 (5 pcs)

– slot inserts 0.7 (10 pcs)

– drill bit 7.7 (1 pc)

– drill bit 7.8 (1 pc)

– clamp fi 14 (2 pcs)

– driven holder for milling (1 pc)

– driven holder for finger joint cutter (1 pc)

– standard short holder (2 pcs)

– standard long holder (1 pc)

– feeder made of plastic (1 pc)

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe