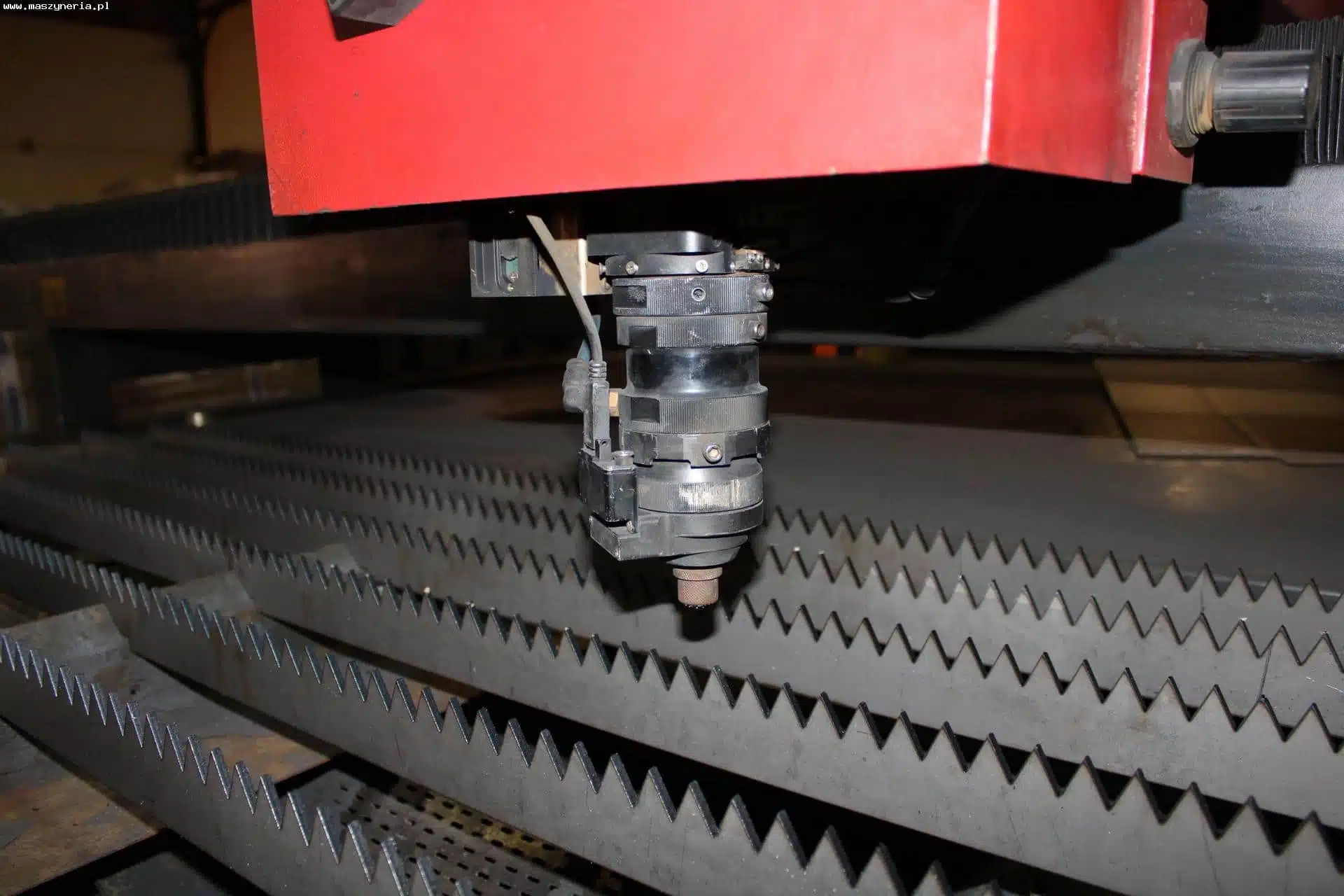

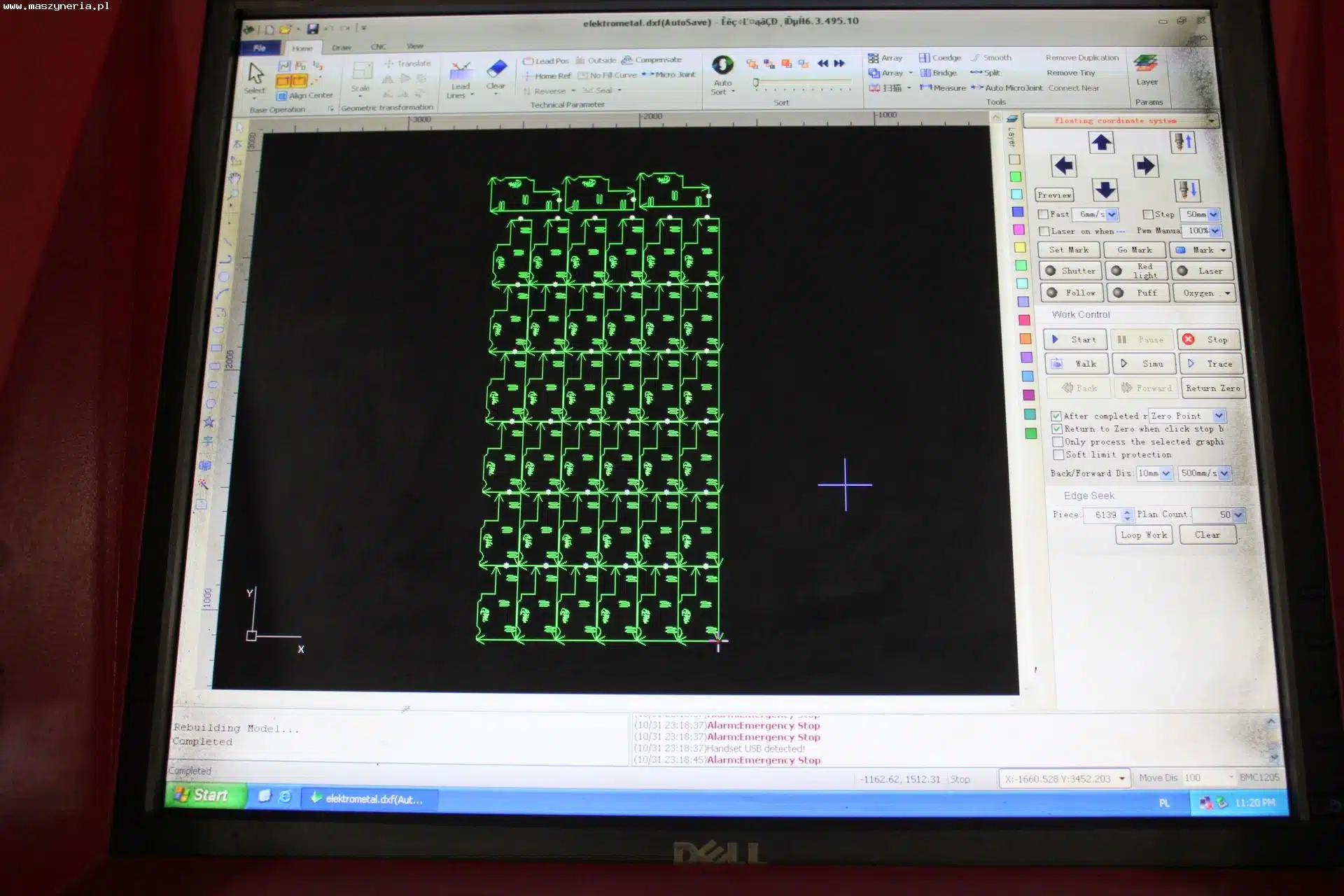

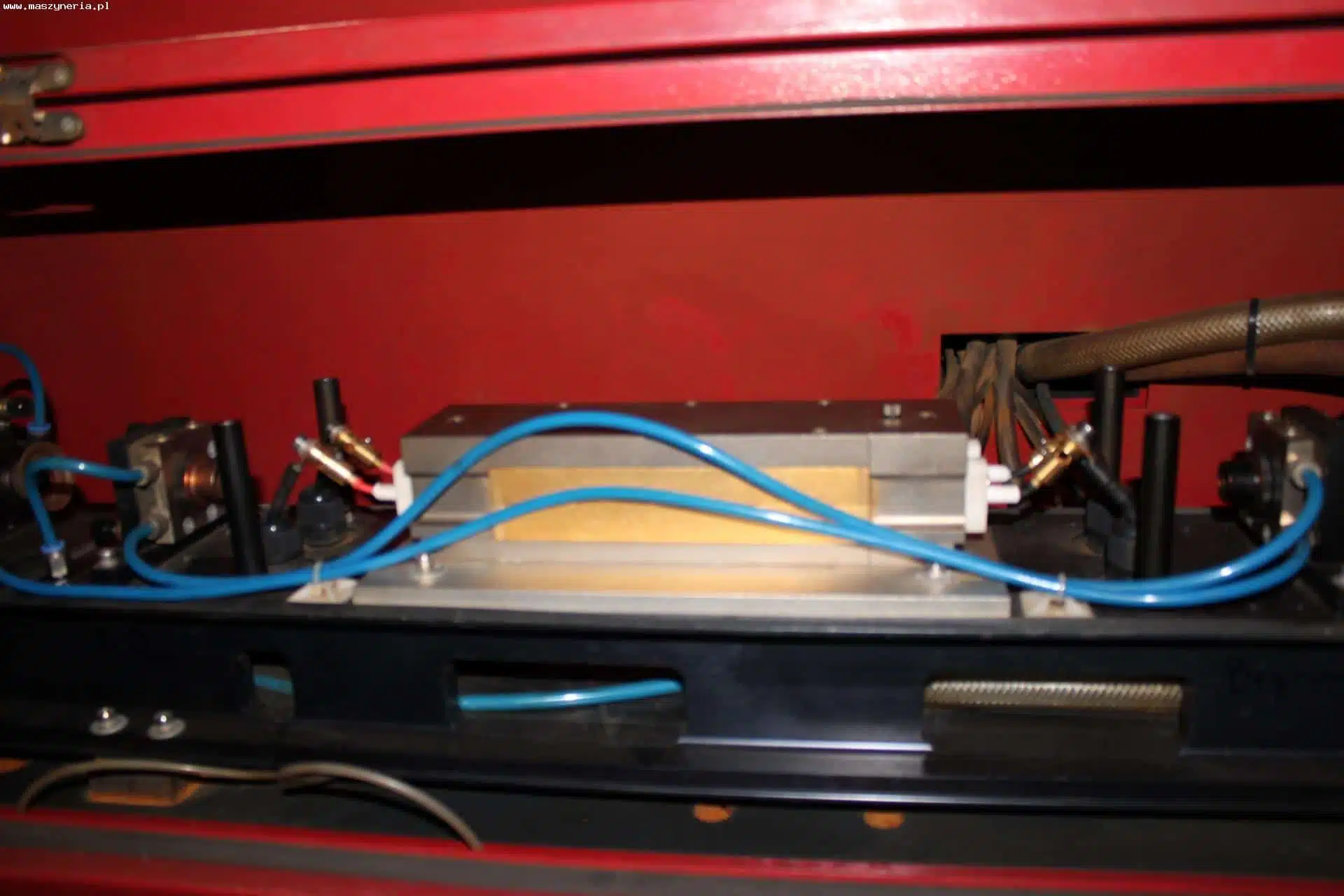

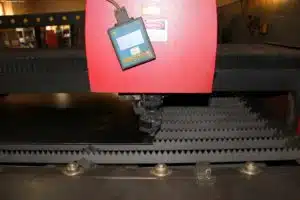

The YAG 620-GC3015 laser was produced in 2014. It is a 620 W laser. It has a work table of 2500 x 1300 mm. It has an external adapter for cutting 2D pipes and profiles in 3D. The machine consists of a control cabinet with a PC, a color monitor and a touch screen for setting the cutting parameters. The laser is equipped with a DAIKEN air conditioner with a function of reheating at low ambient temperatures. The machine has a device with a cooling unit with R134A, a resonator with a power of more than 620 W, with a system of double optics 150 mm and 100 mm and a cutting head with anti-collision function and automatic-optical focusing, which enables cutting corrugated sheets. The laser has an automatic lubrication system for all axes, a special Y-axis bellows protection with stainless steel 1.4304, an automatic feeder for small cut parts, Windows software, LaserCut and 2D Cad. The nominal connection power of the laser is 25.5 kW, the maximum power consumption during operation is 15.3 kW. The machine is powered by 3 x 400V / 50Hz / 3 x 63 AMP. The YAG 620-GC3015 laser has an overvoltage protection system installed, power phase failure sensors, protective and operational zeroing, and grounding. It enables cutting black steel 8 mm thick, stainless steel up to 6 mm thick and the walls of pipes and profiles up to 4 mm thick.

Technical data of the YAG 620-GC3015 laser

– power: 620 W

– table size: 2500 x 1300 mm

– black steel cutting: 8 mm

– stainless steel cutting: 6 mm

– wall cutting of pipes and profiles: up to 4 mm

– resonator, power: 620 W

– external attachment for cutting 2D pipes and profiles in 3D

– laser wavelength: 1064 mm

– frequency: 1-300Hz

– minimum line width: 0.15 mm

– current: 400V / 50 Hz

– positioning accuracy: <+ 0.08mm / 1000mm

- accuracy at zeroing: <+0.04 mm

- maximum cutting speed: 80 mm / s