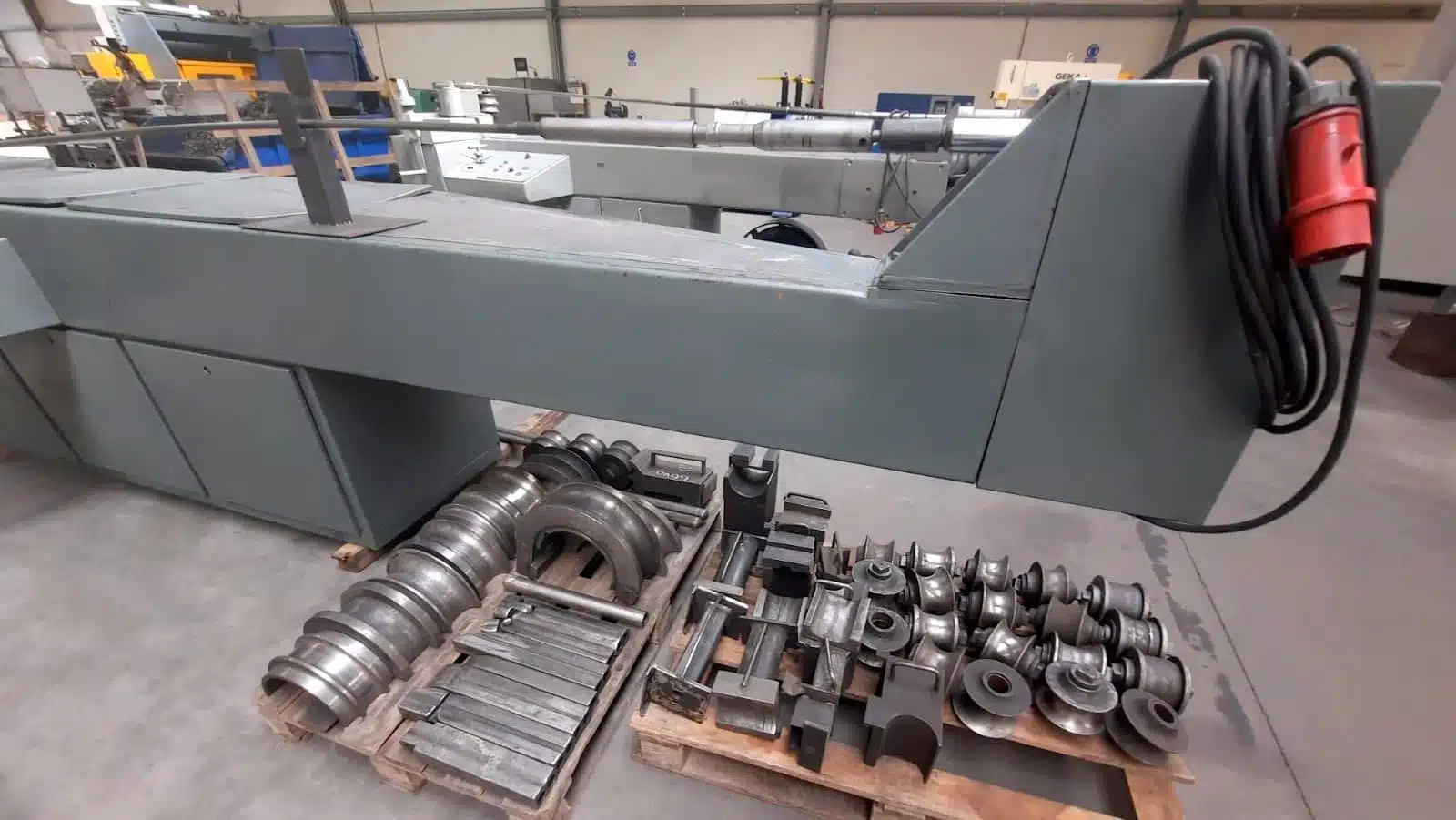

ZREMB GH4 tube bending machine, manufactured in 1983, is used in factories during the precise processing of all varieties of installation tubes. The tube bending is performed in a semi-automatic mode on a cam with the mandrel filling the most deformed section of the tube. The machine comes with a comprehensive range of equipment shown in the accompanying photos. The GH4 mandrel bending machine weighs 2450 kg.

The ZREMB tube bending machine consists of:

– drive mechanism

– mandrel feed mechanism

– guiding mechanism

– control panel mechanism

– hydraulic system

– electrical installation assembly

– frame assembly

Technical specification of the ZREMB GH4 bending machine

- tube diameters: 1 ½”; 2″, 2 ½”; 3″, 3 ½”; 4″

- maximum bending angle: 180°

- bending capacity (30 bends): 180°/h

- head working movement time (180°): 38 s

- head return movement time (180°): 19 s

- curve bending method: cold

- operating mode: semi-automatic

- hydraulic drive of working and auxiliary movements

- maximum hydraulic system pressure: 200 kG/cm2

- power: 5.5 kW

- dimensions (L x W x H): 4620 x 1240 x 1420 mm

- machine weight: 2450 kg

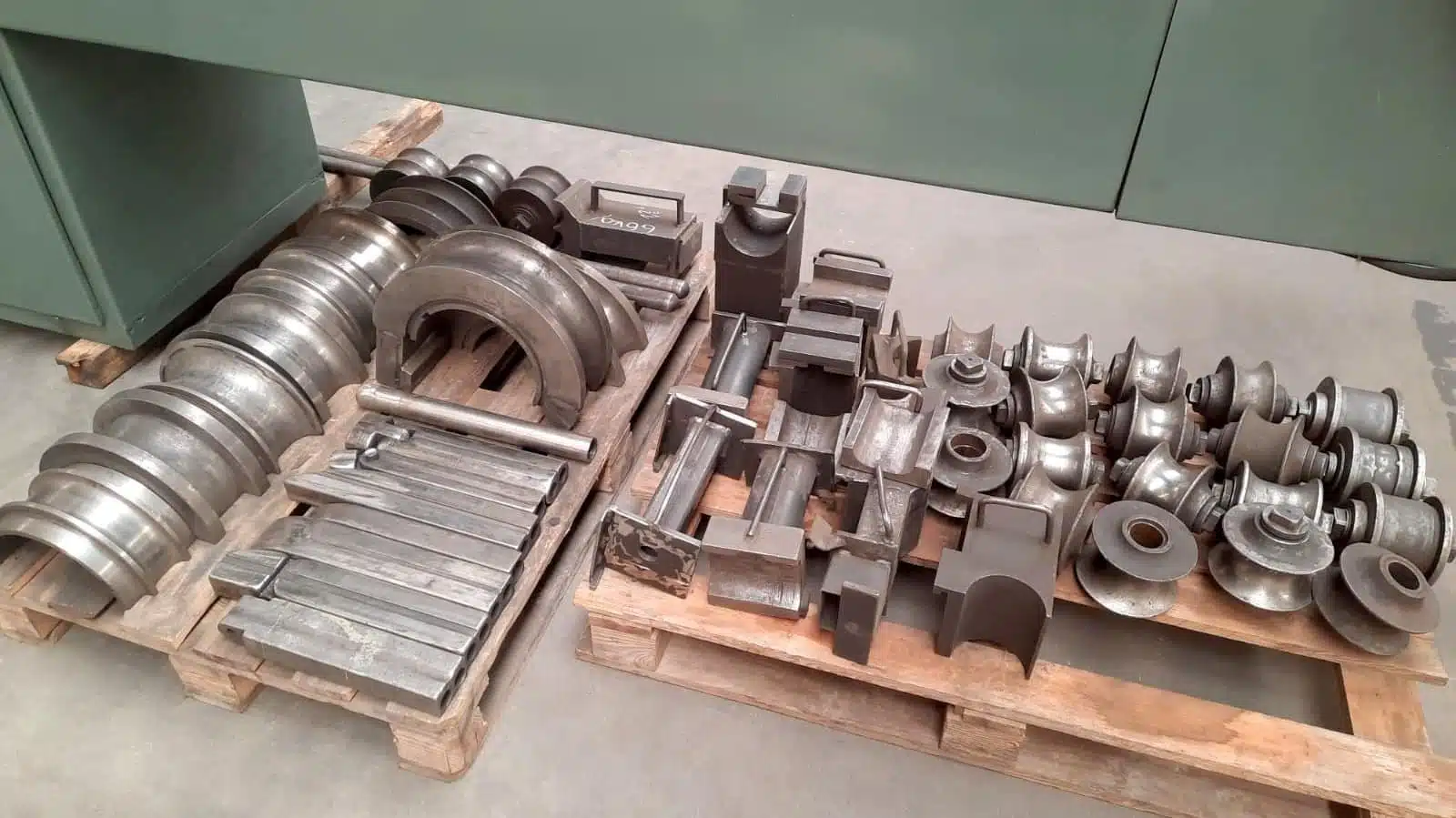

Equipment of mandrel bending machine ZREMB GH 4

- tooling for bending profiles with dimensions

- tooling for bending strip profiles with dimensions

- mandrels

- tube clamps and clamping rings

- rollers for tube 60.3 mm and 76.1 mm

- 2″ tube – set of rollers and mandrel

- 1.5″ tube – set of tooling without clamping

– 80 x 50 x 3 mm

– 50 x 50 x 3 mm

– 90 x 55 x 2,6 mm

– 60 x 30 x 2 mm

– fi 51.5 mm

– fi 69 mm (2 pieces)

– fi 96 mm

– fi 103 mm

– 76.1 mm

– 100 mm

– 109 mm

The tooling set for one type of tube includes: cam, clamp and clamping ring, mandrel and 3 pieces of rollers.

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe