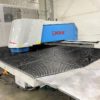

BOSCHERT COMPACT 1250 ROTATION-INDEX punching machine was manufactured in 2014 in Germany. The machine, used in precision nibbling, punching and stamping of workpieces, is characterised by excellent stability and rigidity even during demanding series machining. Workpieces with a maximum thickness of 10 mm are machined with a force of 28 tonnes on a large brush table, protecting sheet metal surfaces from scratches and scrapes.

The punching tool head is equipped with a ROTATION tool station drive, which smoothly rotates each punching tool in a range of 360°, guaranteeing fast and trouble-free machining of even the most complex shapes. The punching machine is also equipped with a BOSCHERT einfach besser TFT control panel with an intuitive BOSCHERT CNC 32050 CNC controlle for programming machining modes and controlling the machine operation. The total weight of the machine is 8400 kg.

Technical specifications of the BOSCHERT COMPACT 1250 ROTATION-INDEX punching machine

- CNC control: BOSCHERT CNC 32050

- maximum punching force: 28 t (280 kN)

- feed rate in X/Y axis: 2000/1250 mm

- maximum workpiece thickness (clamp opening): 6 mm

- maximum workpiece thickness (when working with bumper): 10 mm

- maximum stroke rate (nibbling mode 1 mm): 250/min

- maximum punch diameter: 105 mm

- TFT control panel: BOSCHERT einfach besser

- ROTATION drive for stepless tool rotation in the machine tool head

- brush table

- switch-on time: 23634h

- compressed air requirement (at pressure of 6 bar): approx. 10 l/min

- noise level: > 95 dB(A)

- electrical connection: 25 kVA

- power supply: 3x 400 V; 50 Hz

- dimensions (L x W x H): 4042 x 4118 x 2020 mm

- weight of machine COMPACT 1250 ROTATION-INDEX: 8400 kg

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe