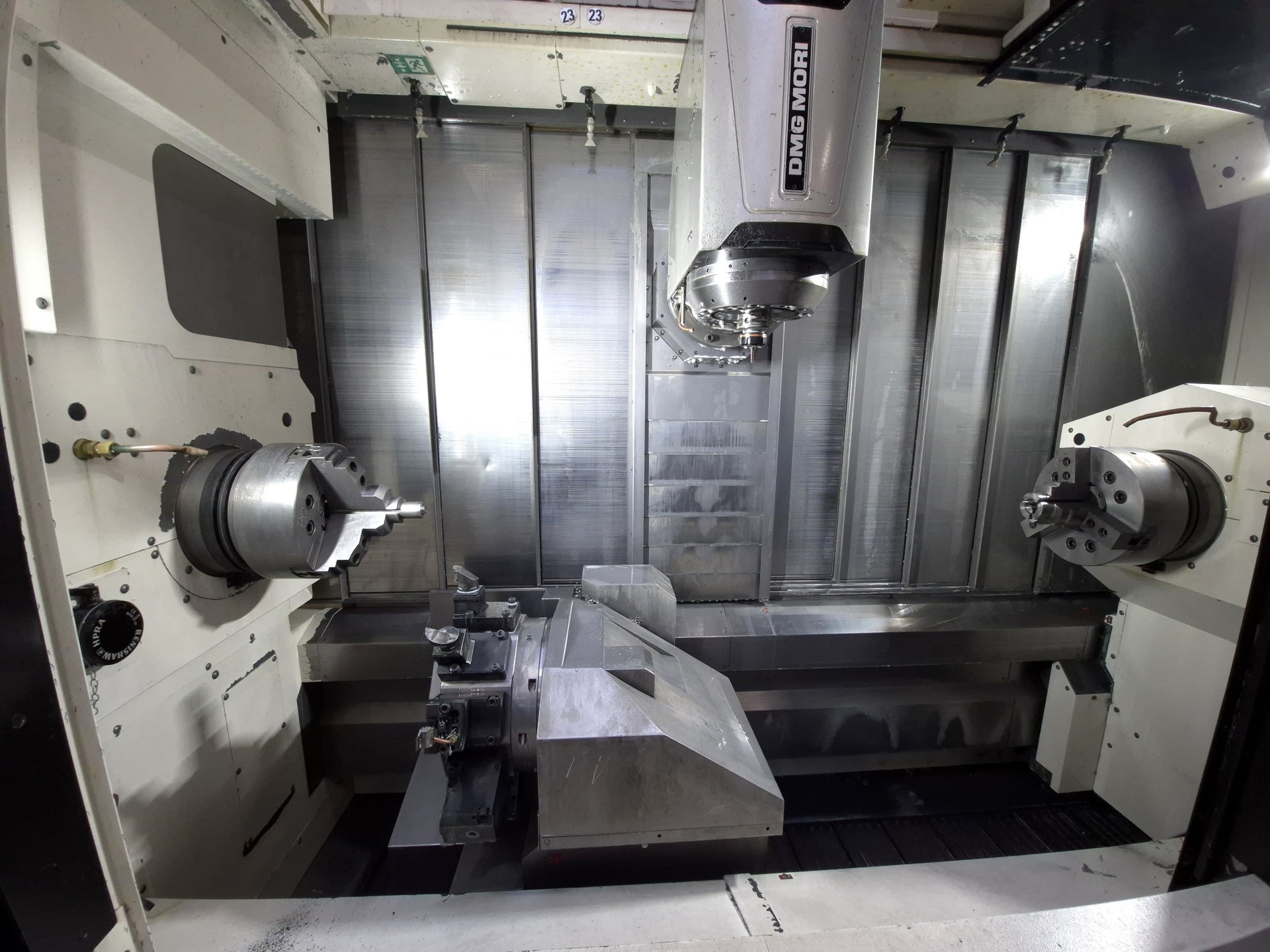

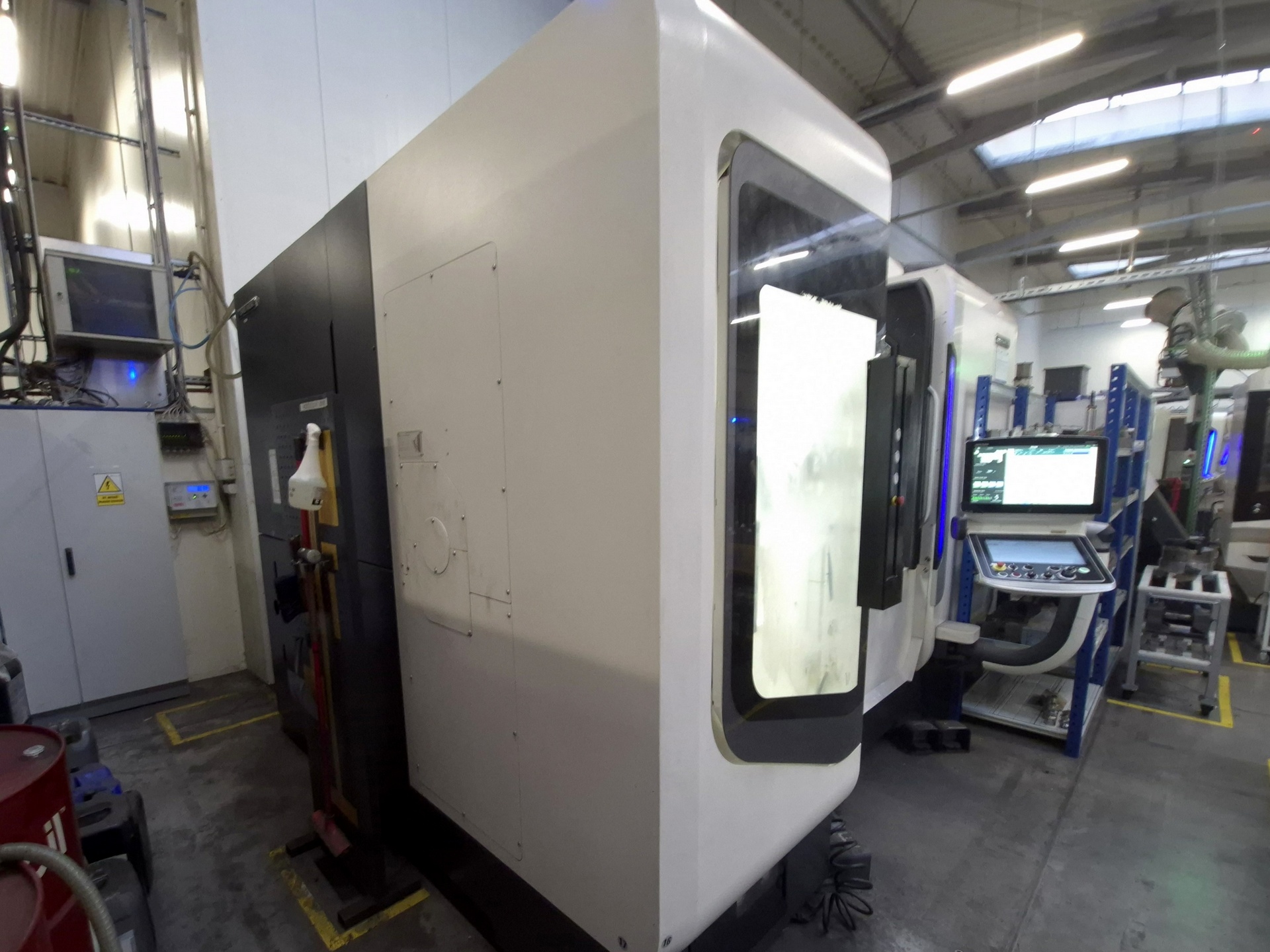

DMG MORI NTX 2000/1500 SZM CNC turn-mill center was built in 2018 in Japan by DMG MORI CO., LTD. The machine on offer is an excellent choice for the mass production of precision parts, which are used in such industries as automotive or aerospace. This is because the NTX 2000/1500 SZM enables simultaneous turning and milling of workpieces with even the most complex geometries, in a single working cycle. The combination of these two processes significantly reduces production costs, as well as overall working time.

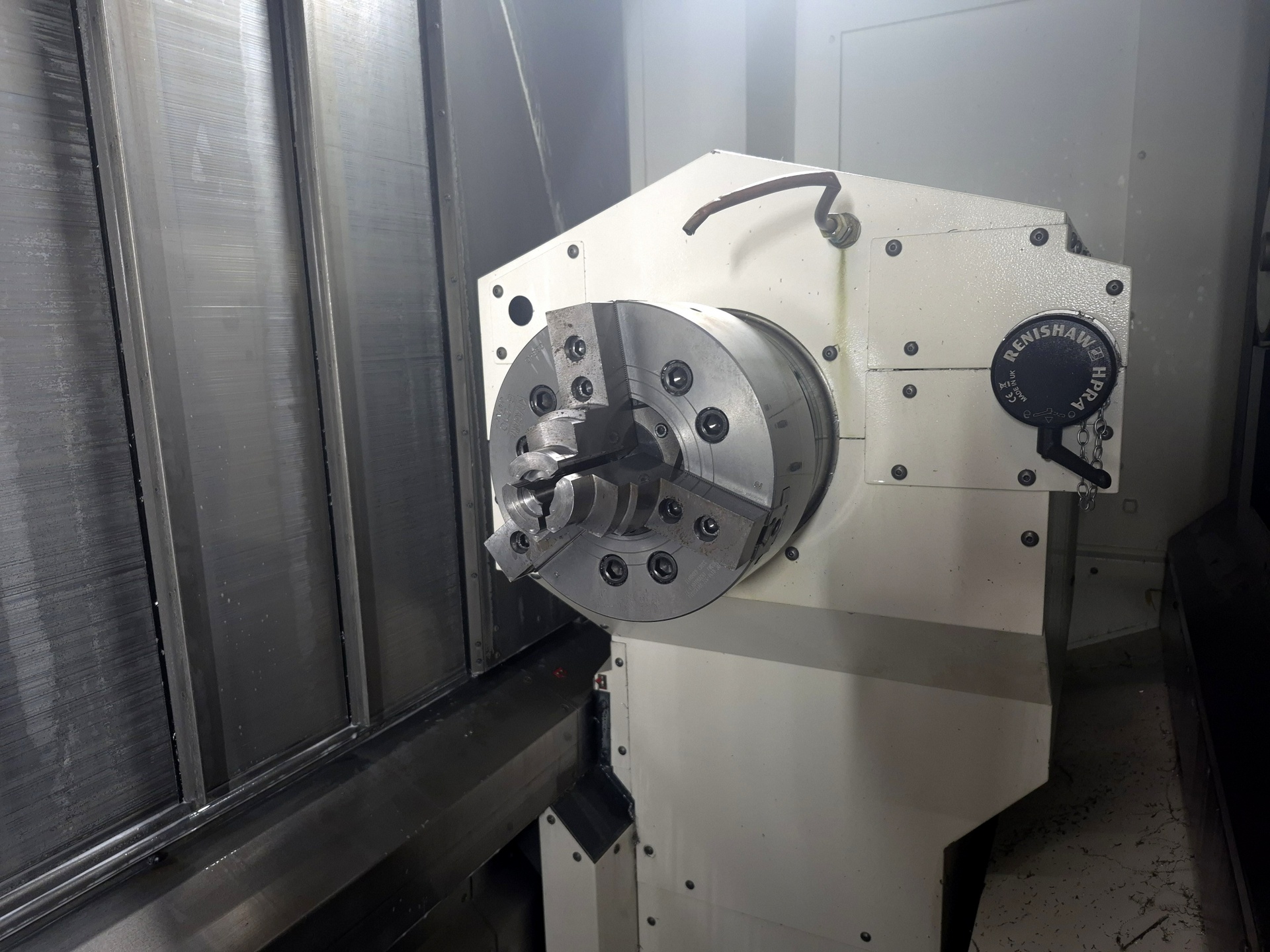

The machining process is performed by using the state-of-the-art technology available on the market. It includes, among others, two spindles with a labyrinth cooling system. This system was designed for frequent use of high-pressure coolant. It ensures a constant zero-point height throughout the working cycle, regardless of the amount of generated heat. To limit the effect of thermal expansion, the temperature rise is dampened by an spiral oil jacket, which surrounds the spindle during machining. The spindle cone is in turn continuously purged with compressed air.

The rotary B axis uses a DDM (Direct Drive Motor). The motor directly transfers power to the rotary axis without the use of gears, eliminating backlash. This solution, compared to conventional worm gear systems, significantly improves productivity and guarantees fast feeds. In addition, to achieve a smooth tool feed, the SVC function reads software commands in advance to control the tool tip and automatically applies compensation. All this ensures better surface quality and shorter cycle times during simultaneous, 5-axis machining of workpieces with even the most complex geometry.

The NTX 2000SZM/1500 CNC machining center is also very easy to operate. It is controlled from a touchscreen control panel with a unified CELOS user interface, which enables consistent machine management, process visualisation and the creation of documentation. The operating system also offers the ability to extend functionality through its compatibility with various applications. The DMG MORI NTX 2000/1500 SZM turning and milling center weighs 16000 kg.

Technical specifications of the DMG MORI NTX 2000/1500 SZM turn-mill machine

General data

- feed in the X1/Y/Z1 axis: 495/± 125/1560 mm

- feed in the X2/Z2 axis: 160/1402 mm

- B axis rotation range: ± 120°

- rapid traverse in the X1,Y,Z1 axis: 40 m/min

- rapid traverse in the X2/Z2/A axis: 30/38/30 m/min

- rapid traverse in the B/C axis: 100/250 rpm

- swing over cross slide: 660 mm

- swing over cross slide (turret): 300 mm

- maximum turning diameter (tool spindle): 660 mm

- maximum turning diameter (turret): 274 mm

- maximum bar diameter: 65 mm

- maximum turning length: 1540 mm

- maximum distance between spindle end and tailstock or between spindle ends: 1760 mm

- compressed air requirement: 650 l/min

- coolant pump motor power: 1.1 kW

- coolant tank capacity: 675 l

- spindle oil cooler tank capacity: 20 l

- hydraulic oil tank capacity: 20 l

- coolant cooler tank capacity: 192 l

- space requirements (L x W): 4110 x 2992 mm

- weight of the DMG MORI NTX 2000/1500 SZM machine: 16000 kg

Main spindle

- maximum rotational speed: 5000 rpm

- bore diameter: 73 mm

- spindle end: JIS A2-6

- internal bearing diameter: 120 mm

- minimum indexing angle: 0.0001°

- drive power (30 min/continuous power): 22/18.5 kW

- torque (15% ED/ 30 min/continuous power): 230/178/159 Nm

Sub-spindle

- maximum rotational speed: 5000 rpm

- bore diameter: 73 mm

- spindle end: JIS A2-6

- internal bearing diameter: 120 mm

- minimum indexing angle: 0.0001°

- drive power (30 min/continuous power): 22/18.5 kW

- torque (15% ED/ 30 min/continuous power): 230/178/159 Nm

Chain tool magazine

- number of positions: 38

- maximum tool diameter (adjacent positions occupied/ adjacent positions empty): 70/125 mm

- maximum tool length: 300 mm

- maximum tool weight: 8 kg

- tool holder: Capto C6

- B axis indexing accuracy: 0,0001°

- maximum tool spindle rotational speed: 12000 rpm

- tool spindle internal bearing diameter: 70 mm

- tool spindle drive power (10 min/continuous power): 18.5/11 kW

- tool spindle torque (10% ED/continuous power): 120/44 Nm

- tool spindle clutch indexing angle: 7,5°

Turret

- number of positions: 10

- maximum rotary tool speed: 6000 rpm

- height of tool square shank: 20 mm

- maximum diameter of boring bar shank: 32 mm

- rotary tool drive power (15% ED/ continuous power): 1.5/1.2 kW

- rotary tool torque (15% ED/ continuous power): 4.8/2.3 Nm

Equipment of the DMG MORI machining center

- CNC controller: FANUC F31iB5

- ERGOline Touch control panel with CELOS unified user interface

- spindle cooling (tool spindle)

- spindle purge system with compressed air

- oil mist separator 200 mm

- chip conveyor

- filter system: KNOLL/ INTERLIT

- automatic shutdown system

- workspace illumination

- foot switch control

- USB port

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe