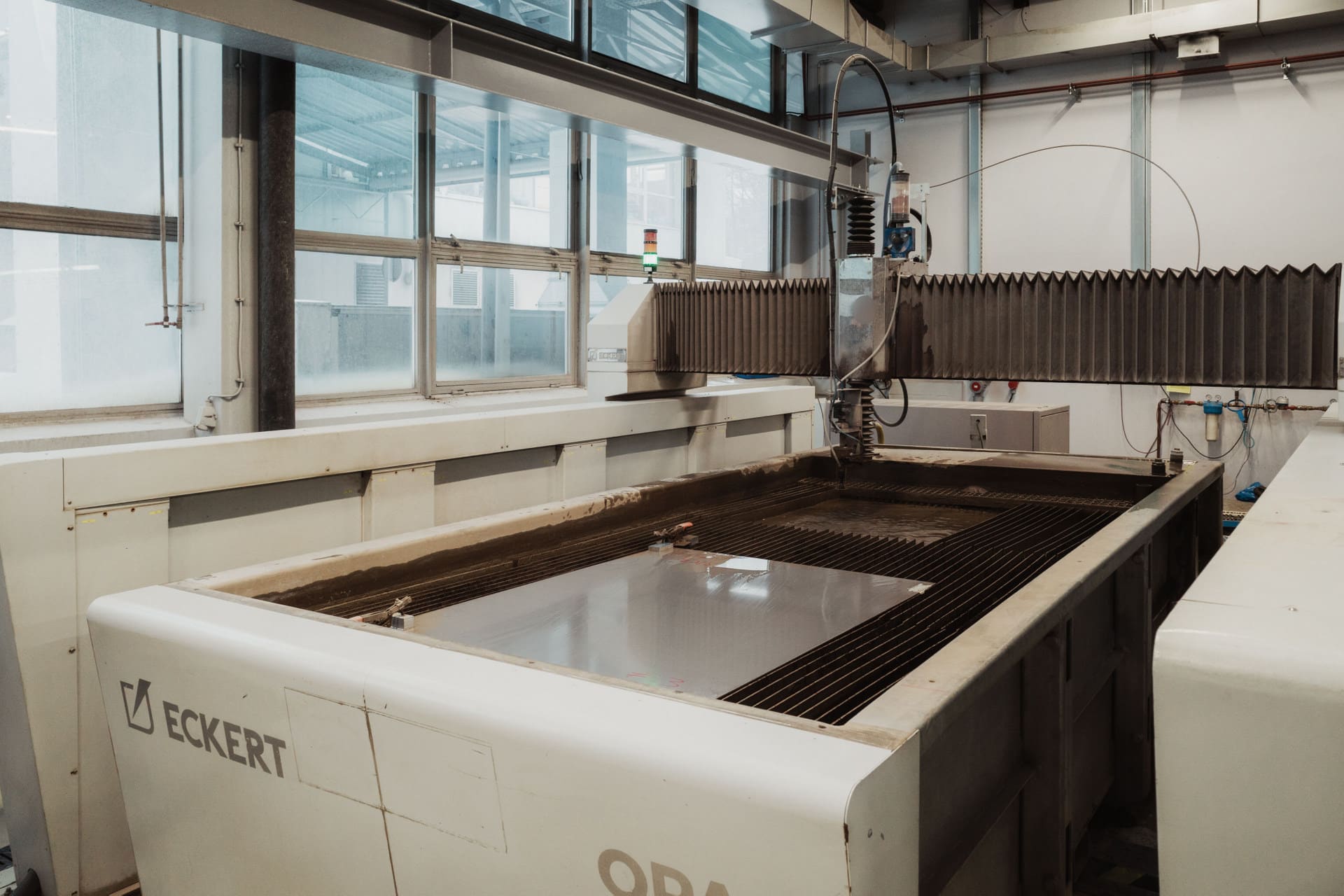

ECKERT Opal WaterJet CNC waterjet cutting machine was built in 2019 in Poland by ECKERT AS Sp. z o.o. The machine is designed for precision machining of a wide range of materials, i.e. metal, stone, wood and plastics. Workpieces with a maximum thickness of 150 mm are machined by means of a reliable cutting head with anti-collision and tool height sensor. During cutting, only water is used, making the process free of harmful fumes and safe for the environment.

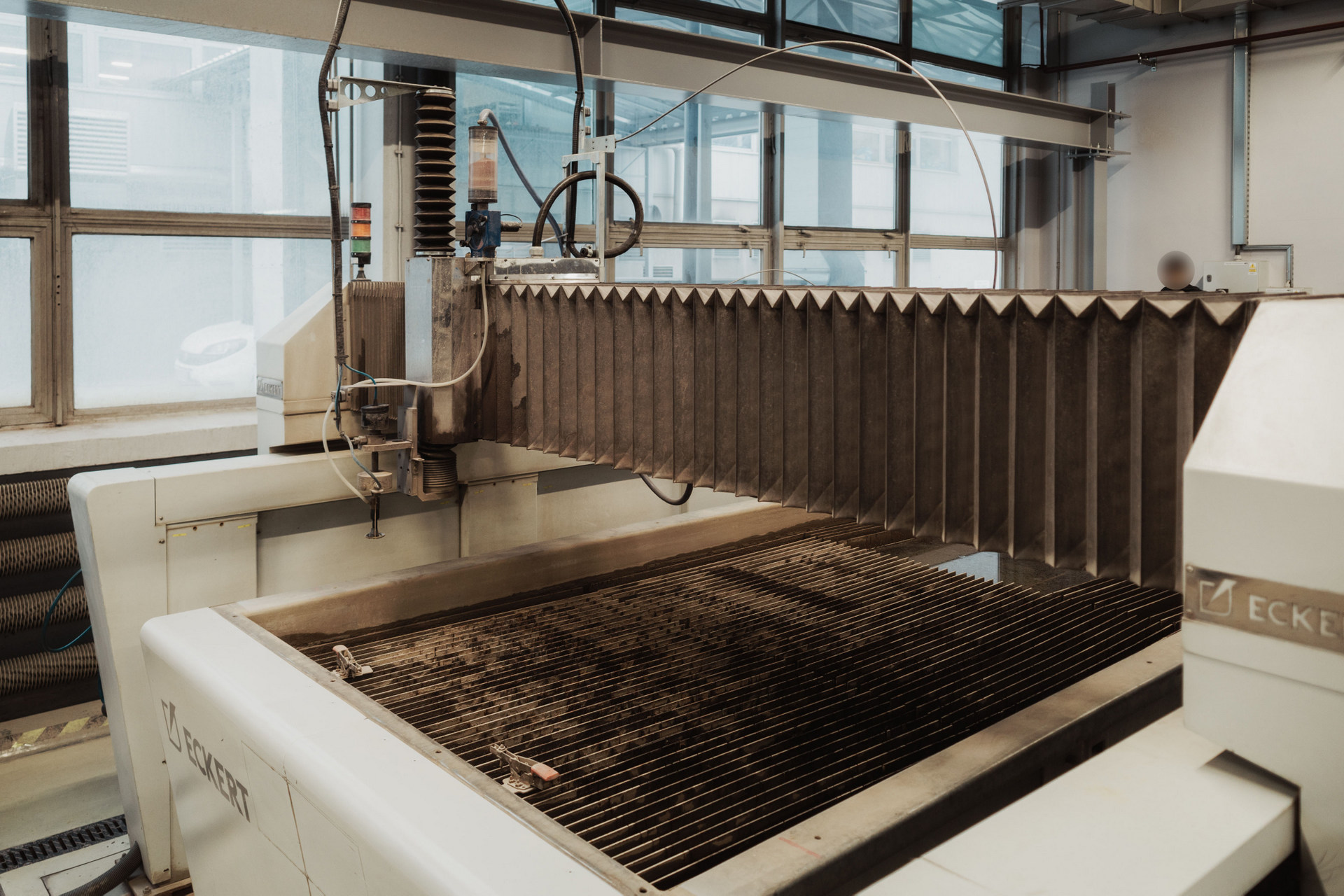

The ECKERT Opal WaterJet is distinguished by its robust water table with a double WEMA grating system. The design made of closed steel profiles ensures high stability during even the most intensive challenges. All travel components, in turn, are protected by bellows covers. This solution guarantees uninterrupted operation of the machine for many years of use.

The ECKERT WaterJet is operated via a state-of-the-art industrial controller with a touchscreen, powerful components and a design that is resistant to extreme conditions on the production floor. Its rich functionality, combined with an intuitive interface, allows the machine’s machining capabilities to be fully utilised. The controller is installed on a free-standing panel that provides exceptional operator comfort and safety, allowing the cutting process to be observed during operation.

Technical specifications of the ECKERT Opal WaterJet water cutting machine

- CNC controller: ECKERT i-Vision

- machinable materials: metal, stone, wood, plastics, etc.

- work table dimensions (L x W): 3000 x 1500 mm

- maximum cutting thickness: 150 mm

- minimal cutting thickness: 0.5 mm

- travel speed: 25000 mm/min

- positioning accuracy: ± 0.025 mm

- power supply of the ECKERT Opal WaterJet machine: 230 V; 50 Hz

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe