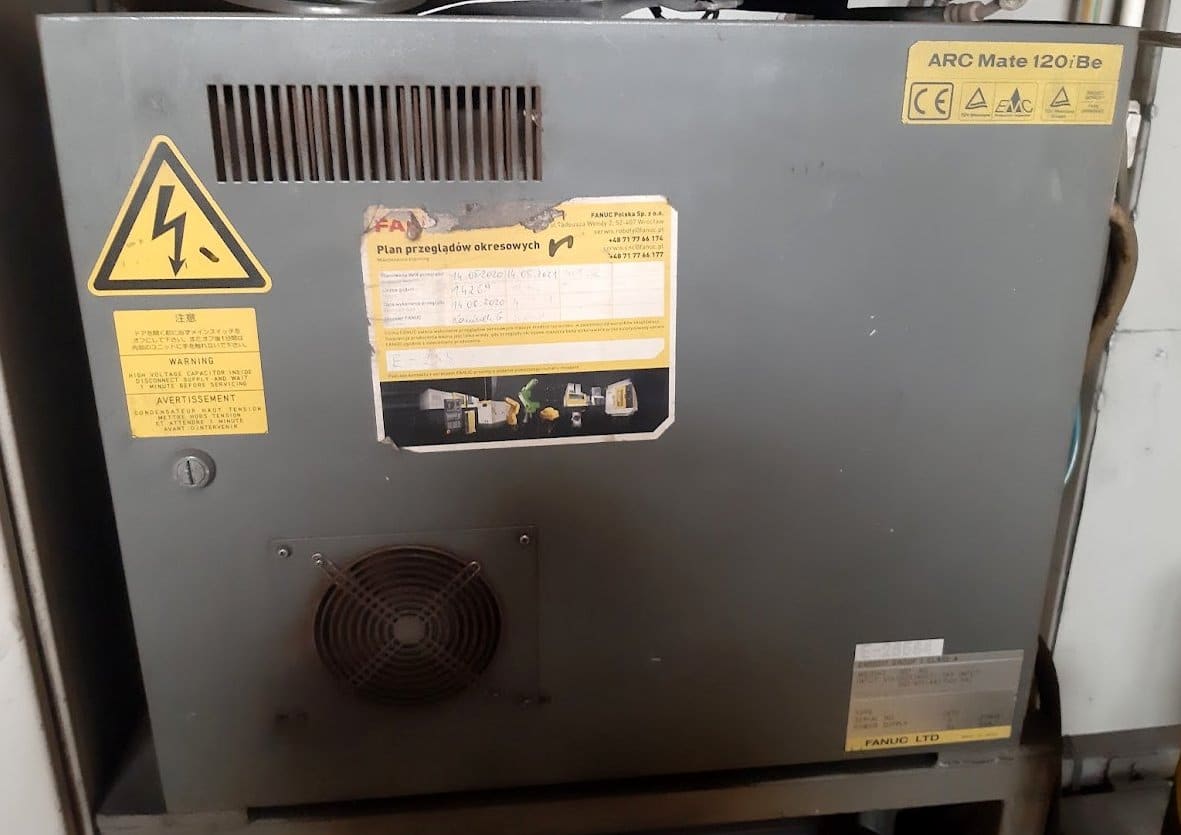

FANUC ARC Mate 120iBE robotic welding machine manufactured in 2007, is used to perform welding processes with the highest quality and precision.

Composition of the robotic welding cell:

– manipulator: FANUC ARC Mate 120iBE

– controller: FANUC SYSTEM R-J3iB Mate

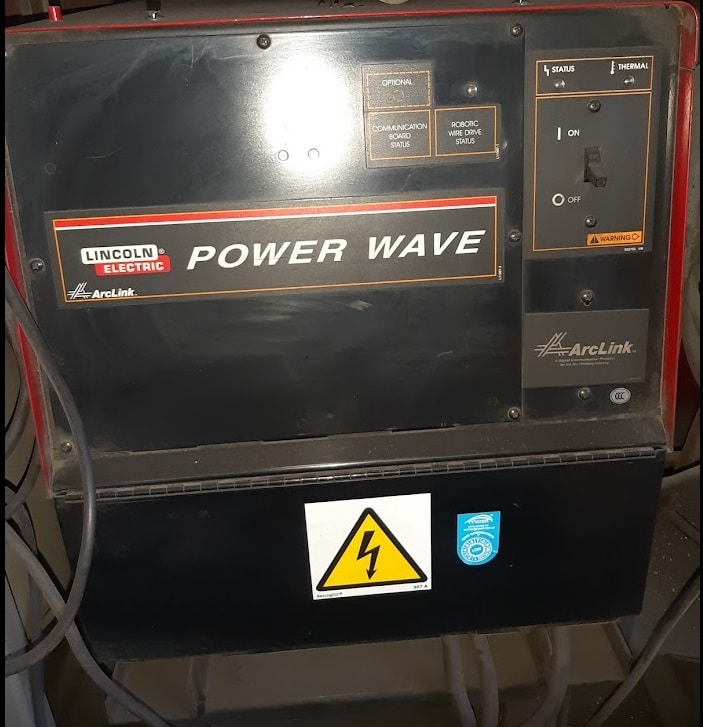

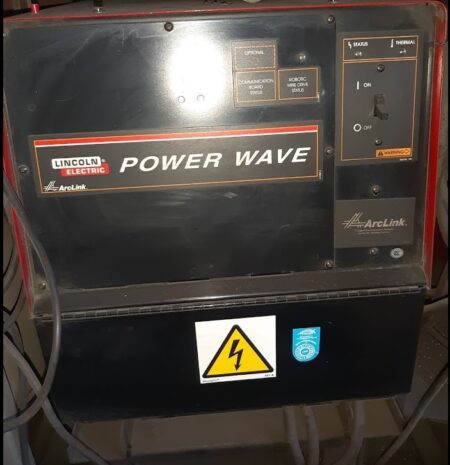

– welding source: LINCOLN ELECTRIC POWER WAVE 455

– portable teach pendant: FANUC

– positioner with 300 kg capacity (2 pcs)

– unloading system

– wire feeder

– anti-collision connector: CAT2-M

– cable set: ABICOR BINZEL

Welding of workpieces is performed by an industrial robot, characterised by high axial speeds and a robust body with a 1667 mm arm reach. Integrated with the machine base, the FANUC SYSTEM R-J3iB Mate controller maximises parameters such as speed or accuracy for maximum productivity and shorter production cycles. The 300 kg capacity positioners used in the welding cell find the optimum position, simplifying work with even the most complex workpieces.

Technical specifications of the FANUC ARC Mate 120iBE welding robot

- number of axes: 6

- arm reach: 1667 mm

- distance from second axis to end of arm: approx. 1700 mm

- distance from second axis to torch: approx. 2000 mm

- payload: 20 kg

- machine axis movement range

- machine axis motion speed

- repeatability: ± 0.08 mm

- mechanical brakes on all axes

- mounting: floor

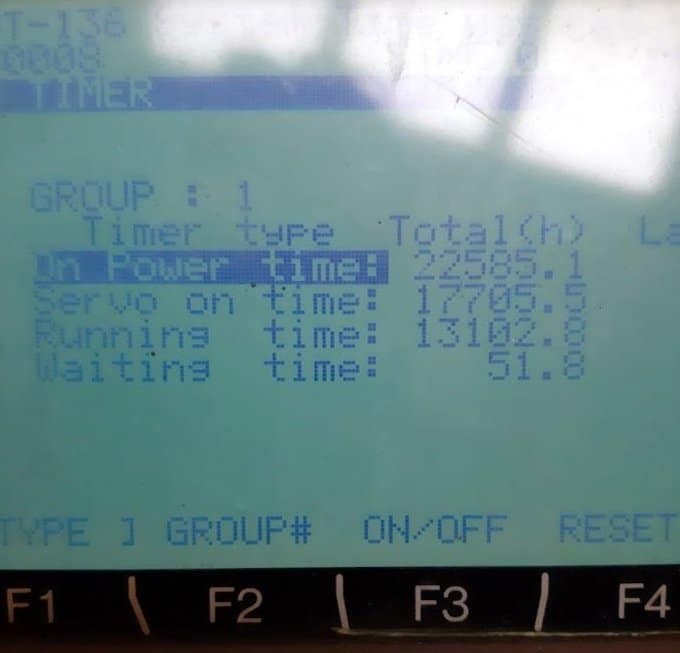

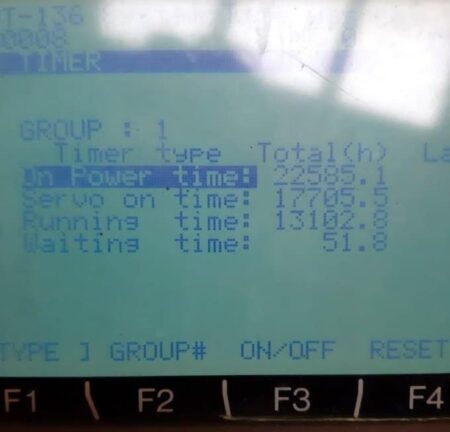

- man-hours: 17705 h

- ambient temperature: 0-45 °C

- technical documentation

- total weight: 230 kg

J1 axis: 340°

J2 axis: 250°

J3 axis: 460°

J4 axis: 400°

J5 axis: 280°

J6 axis: 900°

J1 axis: 165°/s

J2 axis: 165°/s

J3 axis: 175°/s

J4 axis: 350°/s

J5 axis: 340°/s

J6 axis: 520°/s

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe