STAR SV-38R CNC turning centre built in 2015 in Japan, stands out for its unparalleled flexibility and broad functionality, which makes the machine ideal for complex applications in many industries t.e. automotive or aerospace. With the help of two spindles (main spindle and sub-spindle) with C-axis, the STAR SV 38R CNC lathe performs precision machining of inclined surfaces, including front and back angle holes in up to 11 axes.

Both spindles of the machine are driven by reliable, high-power motors, which is used for the versatile use of cutting tools taken from the tool holder or the 10-position turret tool head. A special system for guiding the end of the Z-axis spindle through the headstock also guarantees high rigidity and stability at the cutting point. The STAR SV38R lathe is offered with an extensive range of equipment, including an FMB turbo 5-55 / 3200 A bar feeder, workpiece conveyor and an easy-to-use FANUC Series 31i-MODEL B5 CNC controller with many useful functions. The Swiss-type automatic lathe weighs 4300 kg.

Technical data of the STAR SV-38R Swiss-type lathe

General data

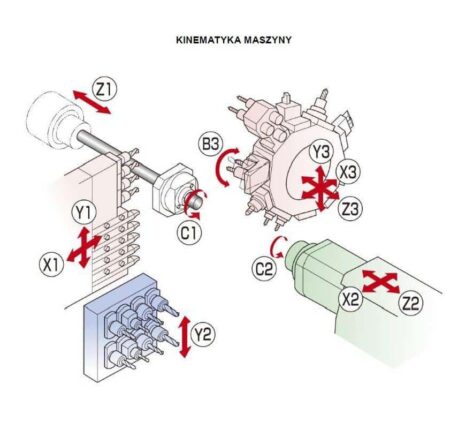

- number of axes: 11 (X1, X2, X3, Y1, Y2, Y3, Z1, Z2, Z3, C1, C2)

- rapid traverse rate in axes X1, X2, X3, Y1, Z1, Z2, Z3: 30 m/min

- rapid traverse rate in Y2 axis: 20 m/min

- rapid traverse rate in Y3 axis: 15 m/min

- maximum turning diameter: 38 mm

- machine switch-on time: 24295 h

- operating hours: 21038 h

- cutting time: 6872 h

- coolant tank capacity: 220 l

- power requirement: 9.5 kVA

- power supply: 3x 200 V; 50/60 Hz

- noise level: 75.6 dB (A)

- dimensions (L x W x H): 3320 x 1440 x 1865 mm

- weight of machine: 4300 kg

Main spindle

- C axis

- maximum rotational speed: 7000 rpm

- maximum spindle stroke: 350 mm

- motor power: 7.5 kW (continuous duty) / 11 kW (10 min/25% ED)

Sub-spindle

- C axis

- maximum rotational speed: 7000 rpm

- motor power: 5.5 kW (continuous duty) / 7.5 kW (10 min/40% ED)

Tool heads

- tool arrangement (tool holder): rotary tools + driven tools

- tool arrangement (turret tool head): 10 positions

- maximum number of tools (tool holder): 5

- maximum number of tools (turret tool head): 10

Through-hole chuck

- maximum drilling diameter: 23 mm

- maximum threading diameter: M16 x 2,0

- number of tools: 3/socket

Driven tools

- number of tools (tool holder): 4

- tool speed (tool holder): 6000 rpm

- number of tools (turret tool head): 2/slot

- tool speed (turret tool head): 5700 rpm

- maximum drilling diameter (tool holder & turret tool head): 10 mm

- maximum threading diameter (tool holder & turret tool head): M8 x 1.25

- motor power (tool holder): 2.2 kW

- motor power (turret tool head): 2.7 kW (continuous duty) / 4 kW (5 min/30% ED)

Equipment of the STAR MICRONICS CNC lathe

- CNC controller: FANUC Series 31i-MODEL B5

- bar feeder: FMB turbo 5-55 / 3200 A

- sub-spindle with air purge

- 8-spindle back machining unit

- 10-position turret tool head

- 5-position tool holder

- synchronous rotary collet unit with air purge

- collet (main spindle and sub-spindle)

- workpiece conveyor

- bar feeder connection

- workpiece breakage sensor

- automatic central lubrication

- hydraulic unit

- pneumatic unit

- coolant level indicator

- leakage switch

- workplace illumination

- RS-232C port

– bar diameter range: 5-65 mm

– maximum bar length: 3200 mm

– feed rate: 0-1000 mm/s

– return speed: 0-1000 mm/s

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe