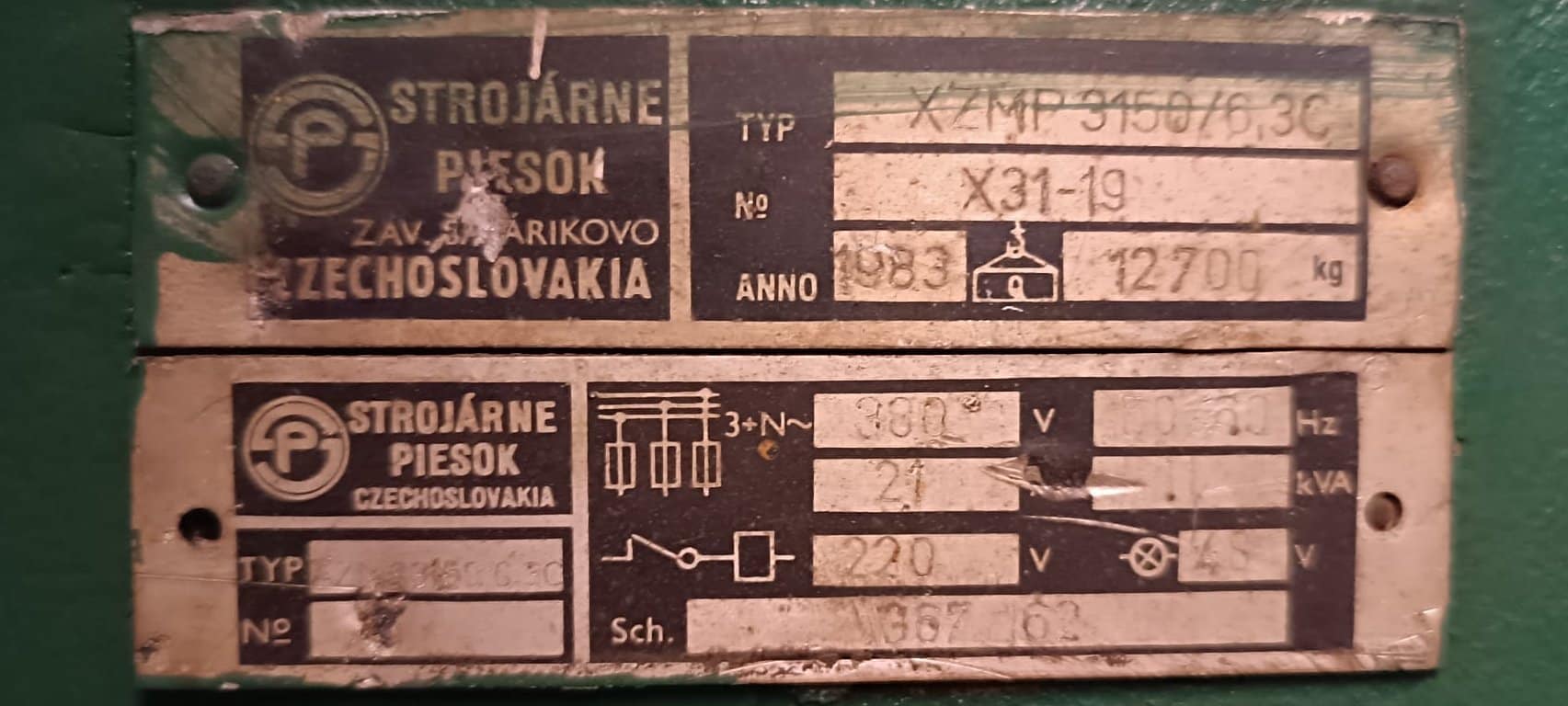

STROJARNE PIESOK XZMP 3150/6.3C 3-roll plate rolling machine built in Czechoslovakia in 1983 is designed for pre-bending and rolling sheet metal into cylindrical or conical covers and segments. The machine is distinguished by a fully welded structure with increased rigidity and three high-quality 300 mm diameter rollers with longitudinal grooves for easy alignment of the sheet.

The bottom rollers, driven by a high-performance motor with two stages of rotation, allow for vertical repositioning during pre-bending and coiling, and also allow for an offset to an inclined position when the claw couplings are opened. As a result, each of the four lower roll bearings can be freely adjusted in the pitch range. The XZMP plate rolling machine has a control panel with a function to monitor the position of the lower rollers directly on the numerical indicators. The total weight of the STROJARNE PIESOK plate rolling machine is 12700 kg.

Technical data of the STROJARNE PIESOK XZMP 3150/6.3C plate rolling machine

- number of rollers: 3

- roller diameter: 300 mm

- maximum sheet metal thickness (pre-bending): 6.3 mm

- maximum sheet metal thickness (rolling): 10 mm

- maximum plate width (pre-bending and rolling): 3150 mm

- maximum diameter of rolled tube: unlimited

- minimum diameter of rolled tube: 360 mm

- rolling speed: 4/8 m/min

- roller repositioning speed: 0.185 m/min

- rolled tube oval: 1%

- motor power: 11 kW

- motor rotational speed: 1460 rpm

- repositioning motor power: 2x 7.5 kW

- repositioning motor rotational speed: 700 rpm

- total power requirement: approx. 28 kW

- hydraulic power unit power: 0.75 kW

- hydraulic system pressure: 4 MPa

- lubrication motor power: 0,37 kW

- power supply: 380 V; 50/60 Hz

- dimensions (L x W x H): 7160 x 1160 x 1400 mm

- weight of XZMP 3150/6.3C rolling machine: 12700 kg

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe