TIMESAVERS 41 SERIE 1350 WRD deburring machine was manufactured in 2004 in the Netherlands. The wide belt deburring machine is used in both small and large production facilities for precision smoothing of sharp edges and finishing work. The machine provides high performance and reliability throughout its service life.

The surface machining of workpieces made from e.g. steel, aluminium and titanium is performed wet by a grinding system comprising a reliable abrasive belt and brush unit. The workpiece is dried at the end of the machining process so that the parts leaving the machine are dry and free of contamination. The deburring machine has an integrated paper belt filter into which the used coolant is transferred at the end of the process in order to separate the swarf and allow the coolant to be reused.

Technical specifications of the TIMESAVERS 41 SERIE 1350 WRD deburring machine

- machinable materials: stainless steel, aluminium, titanium, etc.

- maximum workpiece dimensions (W x H): 1300 x 60 mm

- minimum workpiece dimensions (L x W x H): 80 x 80 x 1 mm

- maximum workpiece weight: 100 kg

- feed rates: 1-10 m/min

- control panel: MITSUBISHI E700

- easily replaceable brush units

- integrated paper belt filter and workpiece dryer

- main switch

- CE certificate

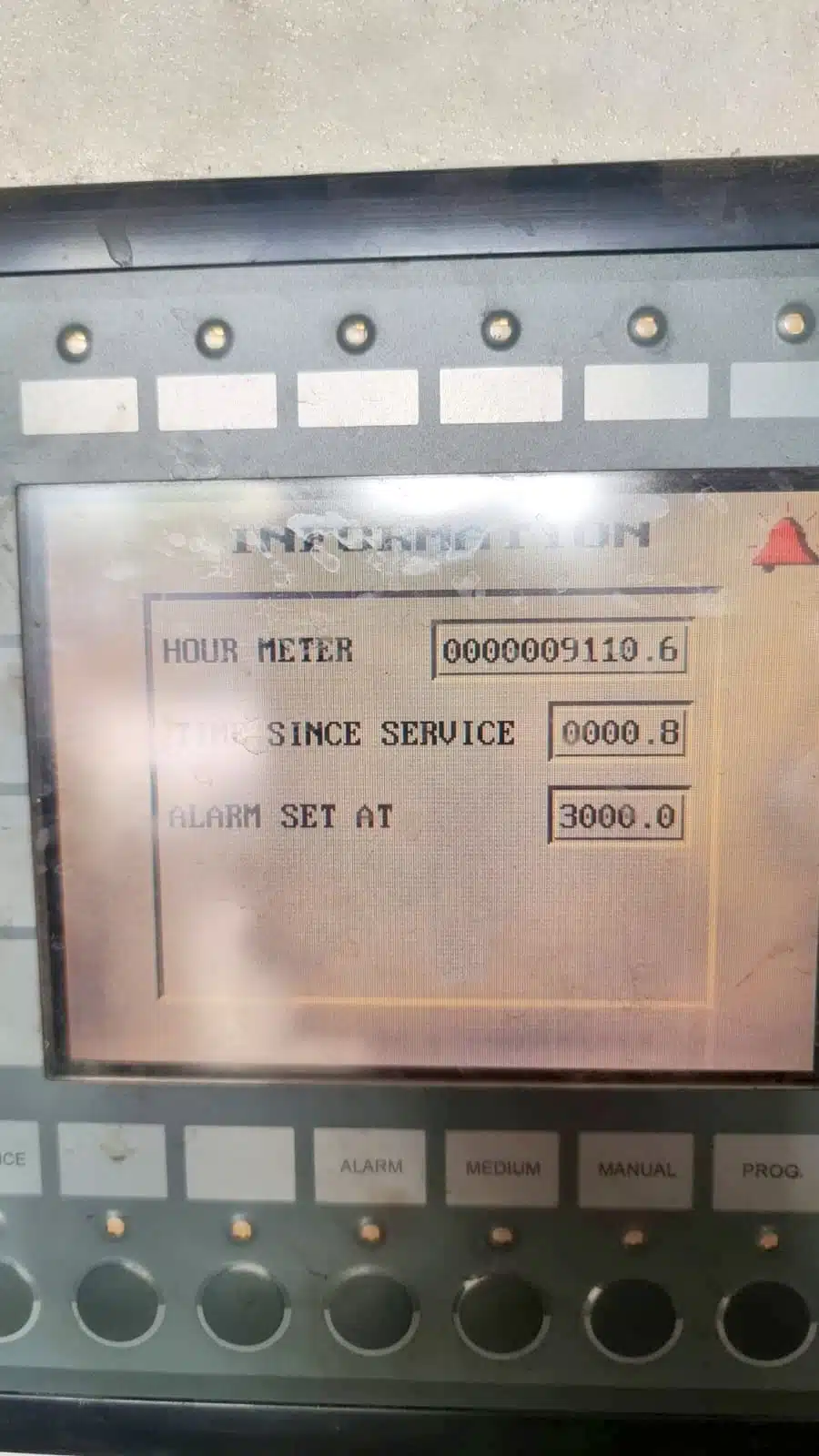

- operating hours: 9110 h

- power: 60 kW

- power supply: 3x 400 V; 50 Hz

- dimensions (overall length x width x height): 3650 x 2130 x 3600 mm

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe