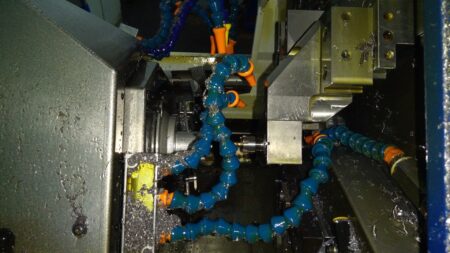

TORNOS MICRO-8 CNC turning centre built in 2008 in Switzerland is distinguished by its extensive machining capabilities, sturdy design made of the highest quality cast iron and compact size. The machine designed for ultra-precise machining of workpieces with a maximum diameter of 10 mm is equipped with two reliable spindles to maximise production efficiency in any production facility, even during the most demanding challenges.

The main spindle and counter spindle with integrated thermal control, retractable collet and ceramic ball bearing run on guides with increased rigidity. Both spindles are powered by reliable FANUC motors, ensuring that the necessary power is supplied for the versatile use of all the cutting tools located in the 20-position linear magazine. The arrangement of the tools in the magazine has been made in such a way as to allow simultaneous machining on the main spindle and the counter spindle. In this way, the TORNOS Swiss-type automatic lathe allows, among others, simultaneous face turning and drilling or simultaneous roughing and finishing.

The offered TORNOS MICRO-8 automatic lathe also features extensive equipment, consisting of, among others, the DONALDSON TORIT DCE multi-chamber oil mist extraction system, the ROBOBAR SBF-210 bar feeder and the easy-to-use FANUC Series 32i-MODEL A CNC control. The MICRO-8 CNC dual-spindle lathe weighs approximately 2000 kg.

Technical specifications of the TORNOS MICRO-8 CNC lathe

General data

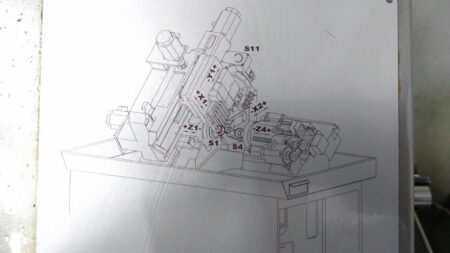

- number of axes: 5 (X1, X2, Y1, Z1, Z4)

- number of axes working simultaneously: 4

- rapid traverse in X,Y,Z axis: 40 m/min

- coolant pump capacity: 120 l/min

- power consumption: 8 kVA

- power supply: 3x 400 V; 50 Hz

- maximum ambient temperature: 35°C

- dimensions (L x W x H): 1670 x 870 x 1650 mm

- weight of bar feeder: approx. 540 kg

- weight of machine: approx. 2000 kg

Main spindle

- speed range: 0-15000 rpm

- maximum bar diameter: 10 mm (8 mm without bar preparation)

- maximum drilling diameter: 6 mm

- maximum threading diameter: M6

- FANUC integrated motor

- thermal stabilisation

- draw type collet: W15-80-0003

- power: 2.2/3.7 kW

Counter spindle

- speed range: 0-15000 rpm

- maximum bar diameter: 10 mm

- maximum drilling diameter: 6 mm

- maximum threading diameter: M6

- FANUC integrated motor

- thermal stabilisation

- pushed type collet: F13-76-00357

- power: 2.2/3.7 kW

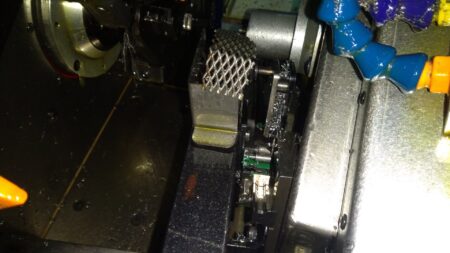

Linear tool magazine

- total number of tools: 20

- maximum number of external surface turning tools: 10

- maximum number of face turning/drilling tools: 4

- maximum number of back turning/drilling tools: 4

- maximum number of transverse tools: 3

- speed range of rotary tools: 5-80000 rpm

- maximum speed of transverse driven rotary tools: 10000 rpm

- drilling diameter: 3 mm

- external turning tool shank cross-section: 12×12 mm

- rotary tool drive motor power: 0.4 kW

Equipment of the TORNOS MICRO Swiss-type lathe

- CNC control: FANUC Series 32i-MODEL A

- automatic bar feeder: ROBOBAR SBF-210

- multi-chamber oil mist extraction system: DONALDSON TORIT DCE

- belt conveyor with workpiece holder

- workpiece ejection system with cleaning and filter

- MINI-DETECTOR type axial tool breakage sensor

- low offset spindle support with 25 mm diameter bore

- support plate for 5 tools with 12×12 mm cross-section

- tool holder for 2 rotary tools with 12×12 mm cross-section

- toolholder with 3 holes of 16 mm diameter

- double ended extension for ER11 collet ø 16 mm

- fixed feed/speed function G96

- pneumatic workpiece separator with workpiece collecting container

- integrated electrical cabinet into the machine frame

- central lubrication system

- coolant pump

- compressed air unit

- coolant pipes to the toolholder with 3 positions

- warning lamp

- workspace illumination

– bar diameter range: 2-10 mm

– maximum bar length: 3200 mm

– feeder capacity: 20 bars

– bar guide closed circuit lubrication

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe