TRUMPF TruLaser 5030 L68 fiber laser was built in 2017 in Germany by Trumpf GmbH + Co. KG. The machine, designed for precision machining of sheet metal made of structural steel, stainless steel and aluminium, is offered with state-of-the-art components and extensive equipment. These include a resonator with the highest energy efficiency, which generates a stable 3 kW fibre optic beam. The mobile, adaptive lens system located in the universal cutting head ensures optimum beam geometry for different sheet thicknesses and materials, resulting in the highest cutting quality at maximum feeds. In addition, special systems incorporated in the machine allow for the machining of waste material.

The laser power is regulated analogously to the feed rate on the advanced SIEMENS SINUMERIK 840D SL CNC control. What’s more, the workshop programming integrated into the control system allows programmes to be created directly from existing geometry data in just 5 steps. The TruLaser 5030 fibre laser also features a reliable multi-chamber exhaust system with compact filters equipped with a spark separator. This device eliminates the contamination generated during processing, while repeated shaking cycles of the filters ensure that their cleaning properties are optimally utilised, throughout its service life.

The entire production process, from sheet loading to the unloading of finished parts, is fully automatic. Along with the machine, the LoadMaster loading system with a sheet stand, suction cups and magnets for separating the sheets works together. This system allows for the safe loading and unloading of workpieces with a maximum size of 3000 x 1500 mm in a very short time. The TRUMPF TruLaser 5030 laser cutting machine with LoadMaster sheet metal loading system weighs 7900 kg.

Technical data of the TRUMPF TruLaser 5030 L68 laser cutting machine

- laser beam power: 3 kW (3000 W)

- maximum sheet metal thickness (structural steel): 24 mm

- maximum sheet metal thickness (stainless steel): 20 mm

- maximum sheet metal thickness (aluminium): 20 mm

- maximum sheet metal weight: 900 kg

- feed in the X/Y/Z axis: 3000/1500/115 mm

- positioning speed with simultaneous operation of the X and Y axes drives: 265 m/min

- smallest programmable step: 0.001 mm

- PA positioning deviation: ± 0.05 mm

- average positioning deviation PS: ± 0.03 mm

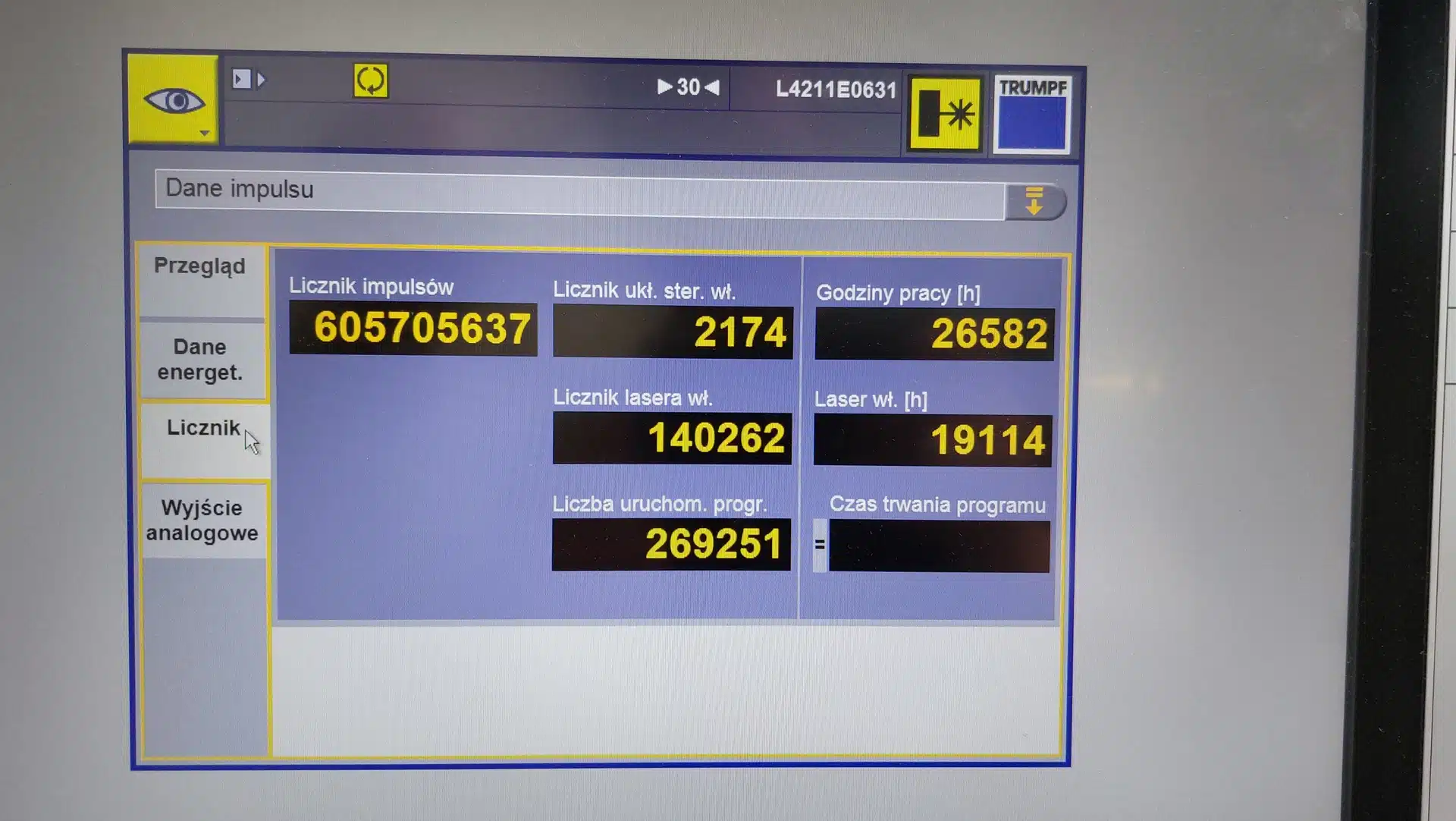

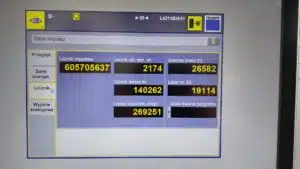

- operating hours: 26582 h

- laser switch-on time: 19114 h

- compressed air connection: 12 bar

- average compressed air consumption: 35 Nm3/h

- N2 nitrogen connection: 33 bar

- O2 oxygen connection: 21 bar

- connection power: 33 kVA

- power consumption (machine with cooling unit): 5-21 kW

- power supply: 400 V; 50 Hz

- weight of laser source: 820 kg

- weight of TRUMPF TruLaser 5030 L68 machine: 7900 kg

Equipment of the TRUMPF laser cutting machine

- CNC controller: SIEMENS SINUMERIK 840D SL

- CAD/CAM software: TruTops

- universal loading unit: LoadMaster

- disk laser: TRUMPF TruDisk 3001

- ControlLine distance measuring system, which maintains a constant distance between the cutting head nozzle and the sheet surface during the cutting process, even with uneven sheets

- ContourLine system, i.e. special approach techniques for cutting holes with diameters significantly smaller than the sheet thickness

- NitroLine system for high-pressure cutting of stainless steel and aluminium alloys

- FocusLine system for setting the focal length according to the material type and thickness without the need for manual adjustments

- PlasmaLine plasma detection system

- PierceLine system for controlling and regulating the burn-in process (reduction in burn-in time by 10-80%)

- FastLine system which optimises the entire cutting process for maximum production profitability

- Microweld system for connecting cut workpiece with waste material by welding points

- AdjustLine system to facilitate the cutting of poor quality materials and thus reducing waste material

- FlyLine system for switching the laser on and off on the fly to reduce processing times for parts with multiple contours cut from thin sheets

- Condition Guide traffic light system providing information on the condition of key components of the machine

- rapid re-production module allowing individual parts to be produced again using an existing programme without having to reprogram the machine

- multi-level light curtains

- laser positioning diode for optical determination of start-point coordinates when moving the zero point on the machined workpiece

- universal cutting head with adaptive lens system

- protective glass to prevent contamination of the lens

- online monitoring of the condition of the protective glass

- adjustable laser power analogous to the feeds

- laser cooling system (water-air)

- pumping diodes for laser excitation

- automatic nozzle cleaning with programmable cleaning cycles

- oil spray unit

- 19″ colour touchscreen operator panel

- integrated technological data presented in the form of tables

- automatic shutdown

- teleservice via internet

- multi-chamber exhaust system

- compact filter

- programmable cutting gas pressure

- electric roller roof over the work area

- CE mark

- USB port

- RJ45 connector

- crosshead and mounting components for rapid assembly of the machine on site