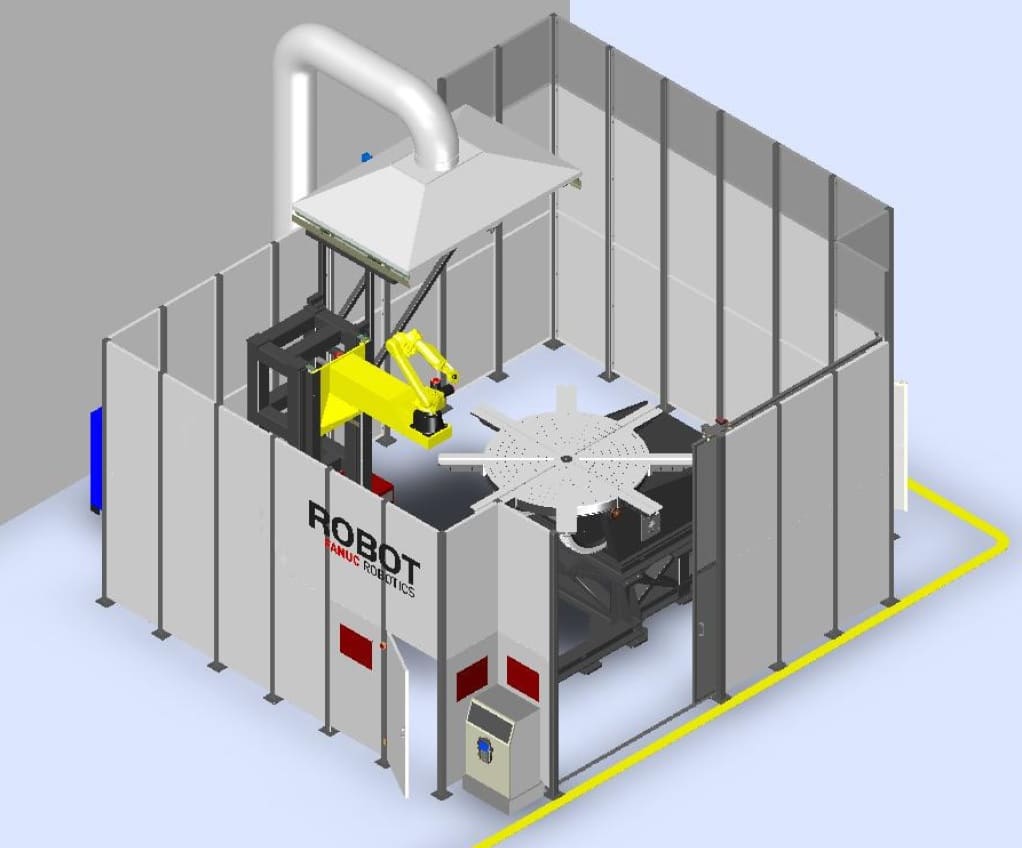

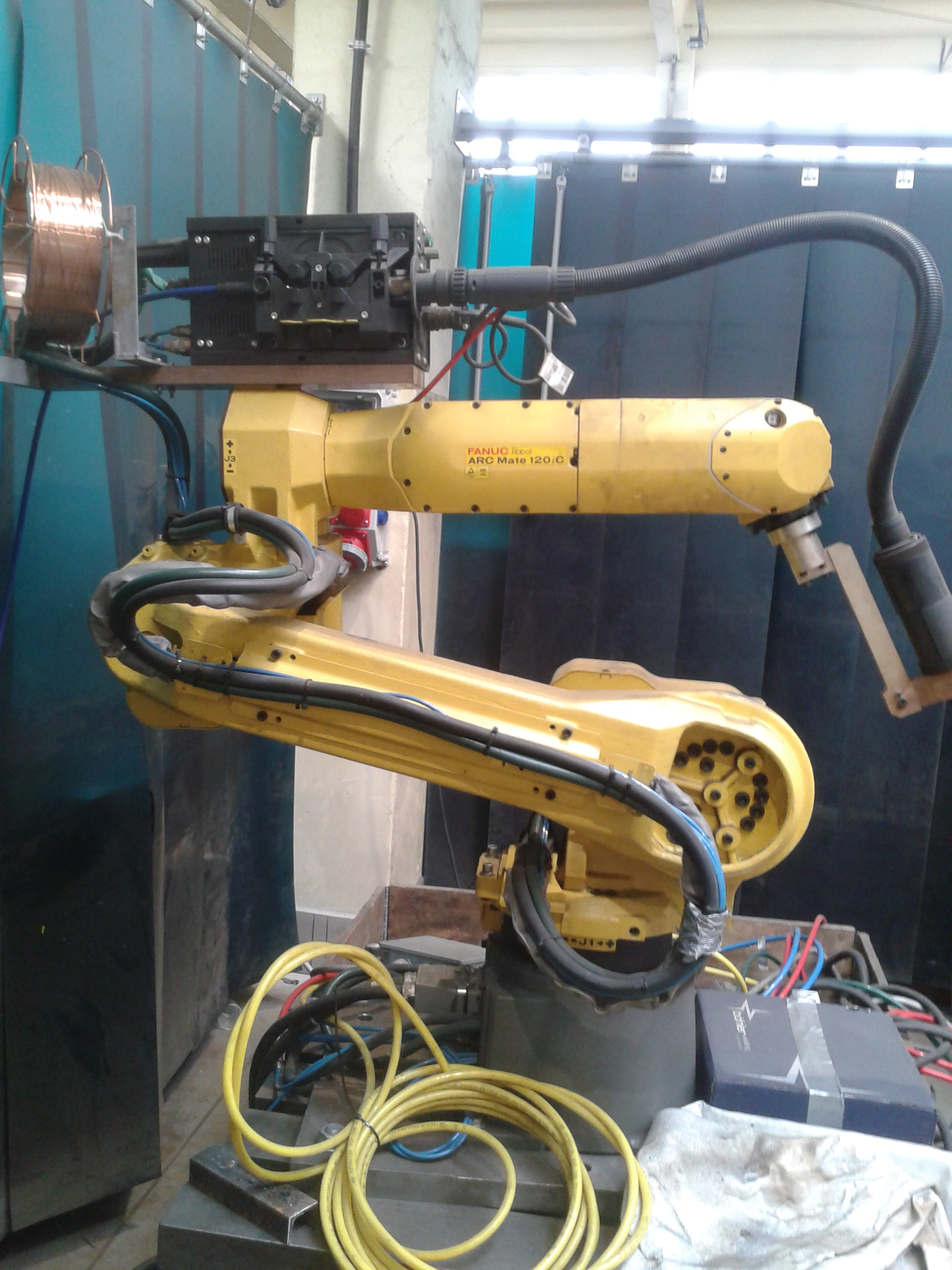

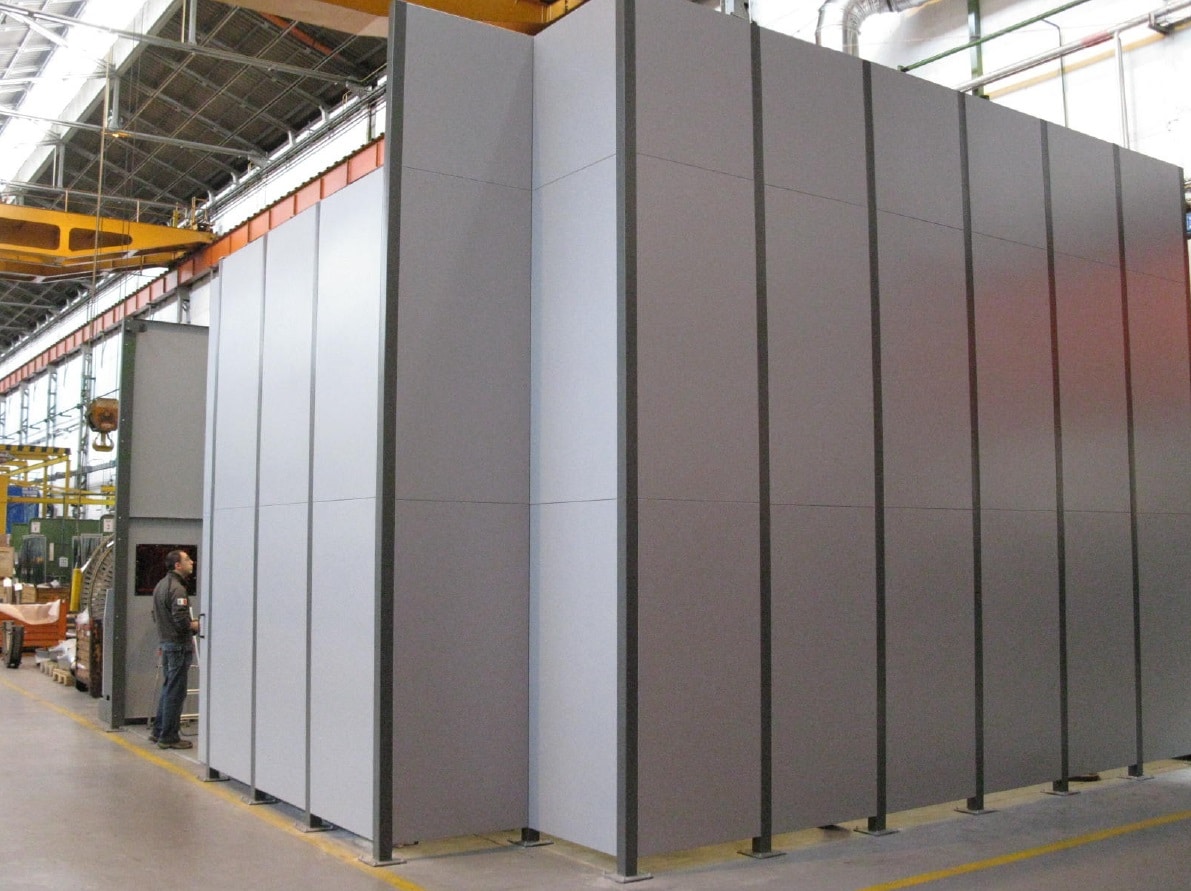

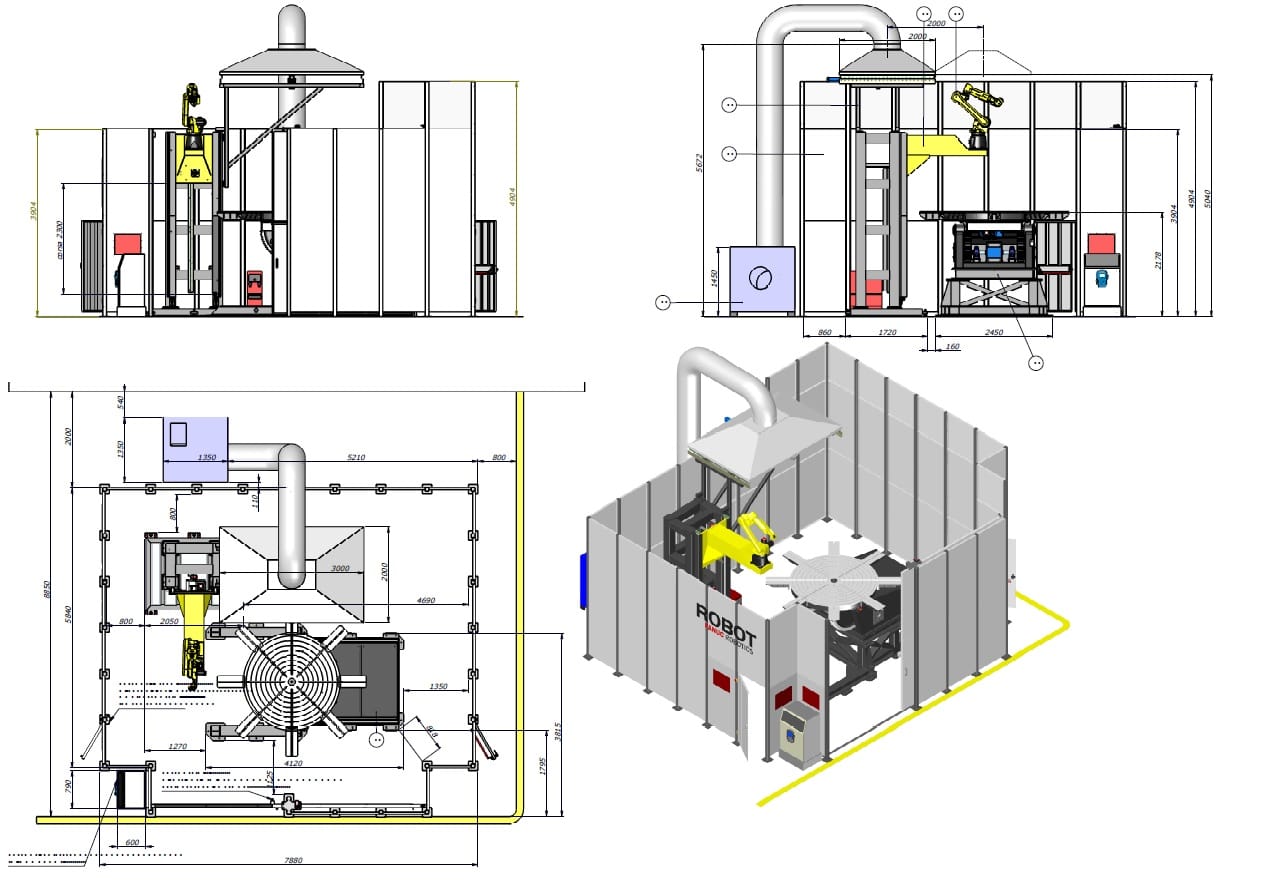

Fanuc ARC Mate 120iC robotic welding cell equipped with a tilting-rotary table (turntable) with a load capacity of 10 tons and a diameter of 3000mm and a welding robot arm Fanuc ARC Mate 120iC. The complete welding cell with the housing was manufactured and installed in 2010. The swivel rotary table is programmed and fully synchronized with the Fanuc Welding Robot. ARC Mate 120iC is an industrial robot designed mainly for fast welding. Six programmable axes, a longer reach and increased payload than in previous models make this robot meet the requirements of automated production halls. The simple and reliable design of the ARCMate 120iC R-30iA provides adequate strength and stiffness, thus ensuring accurate and consistent track quality. The robot can be controlled by a wide range of controllers, and the collision detection system prevents it from colliding with external elements.

Technical parameters of the Fanuc ARC Mate 120iC welding robot

– number of axles: 6

– load capacity: 20 kg

– reach: 1811 mm

– repeatability: + – 0.0800 mm

– robot weight: 250 kg

– mounting: floor, ceiling, angular

Robot motion ranges

– J1 ± 370 °

– J2 ± 260 °

– J3 ± 458 °

– J4 ± 400 °

– J5 ± 360 °

– J6 ± 900 °

Robot movement speeds

– J1 195 ° / s (3.4 rad / s)

– J2 175 ° / s (3.05 rad / s)

– J3 180 ° / s (3.14 rad / s)

– J4 360 ° / s (6.28 rad / s)

– J5 360 ° / s (6.28 rad / s)

– J6 550 ° / s (9.6 rad / s)

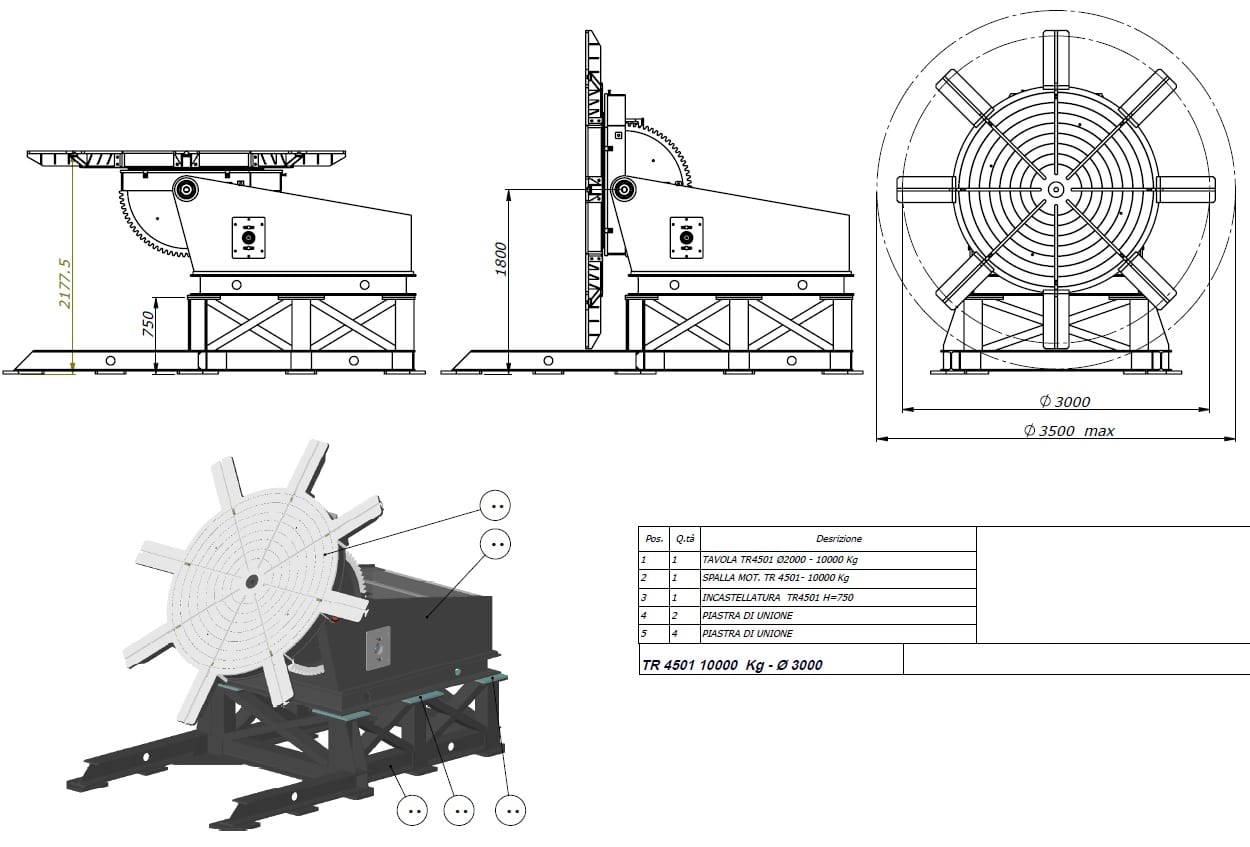

Tilt rotary table cooperating with the Fanuc ARC Mate 120iC robot

– control: CNC

– construction: tilt and swivel

– maximum load: 10t

– maximum diameter of the rotary table: 3000mm

– maximum diameter of the welded detail: 3500mm (vertical)

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano