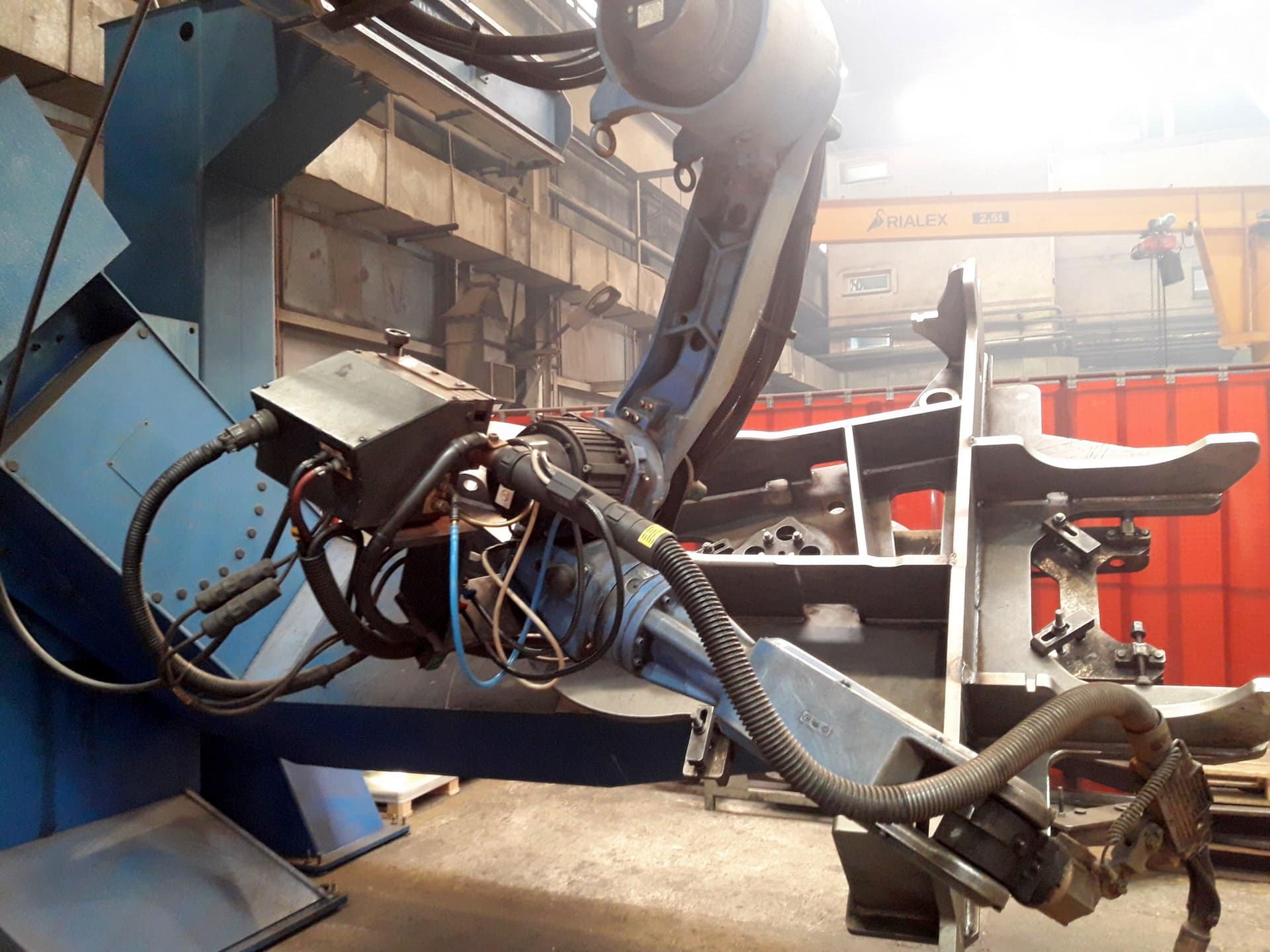

YASKAWA MOTOMAN UP6-A00 robotic welding machine built in Japan in 2004, is used to perform welding processes on large-sized workpieces.

The robotic welding system consists of:

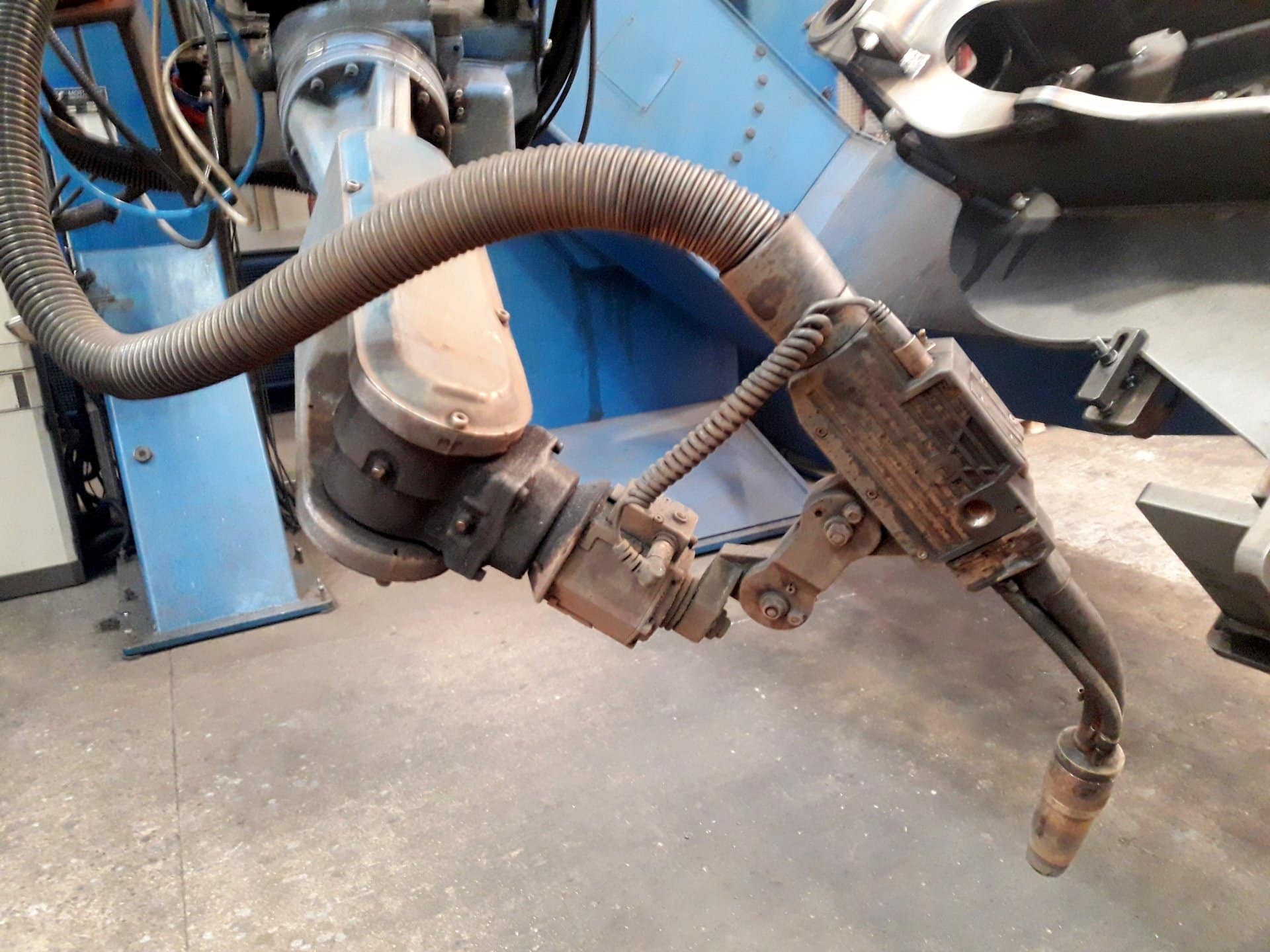

– welding robot: YASKAWA MOTOMAN UP6-A00

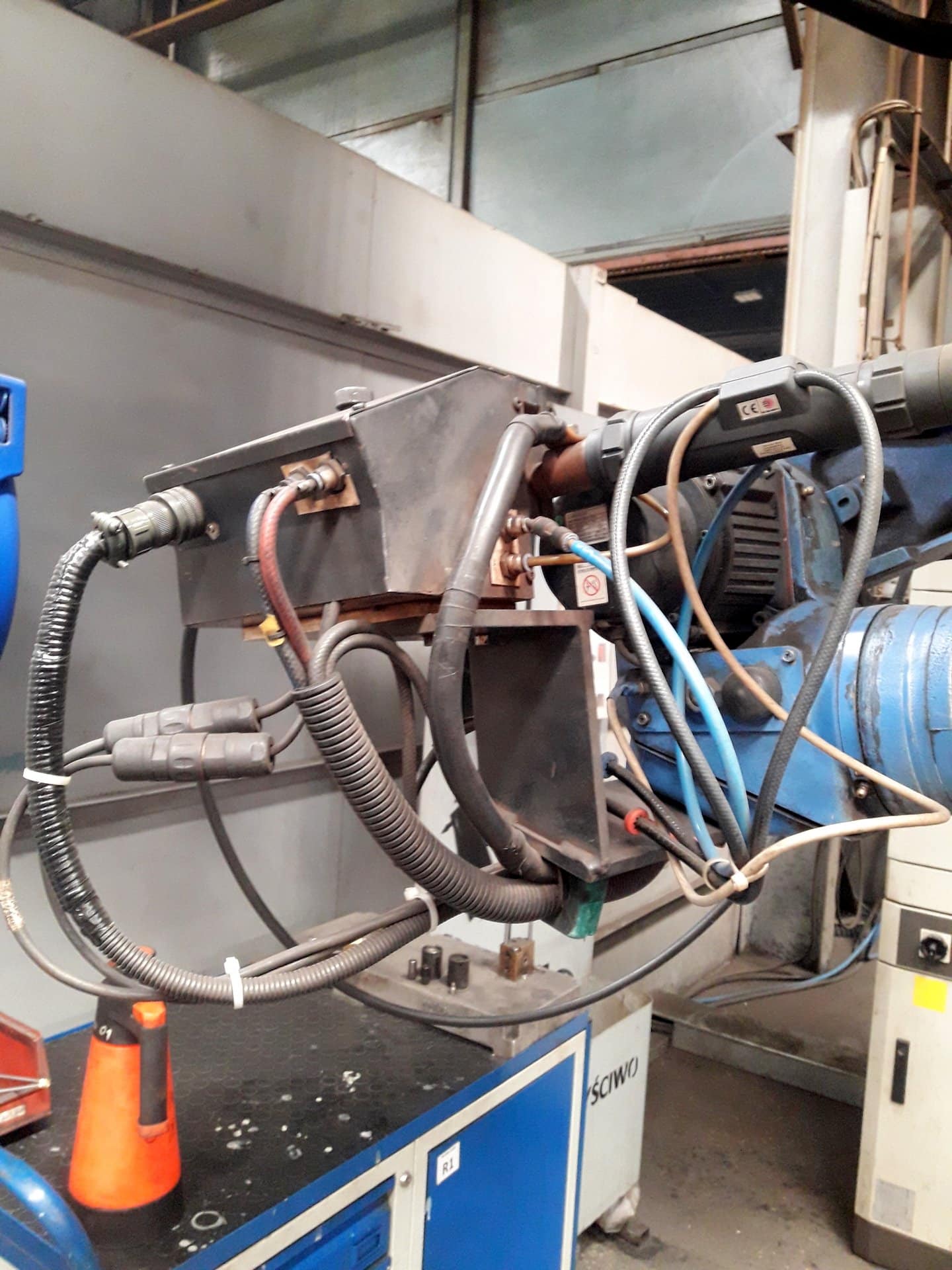

– controller: YASKAWA MOTOMAN XRC

– tilt-rotate positioner: YASKAWA MOTOMAN MT1-3000-S2X

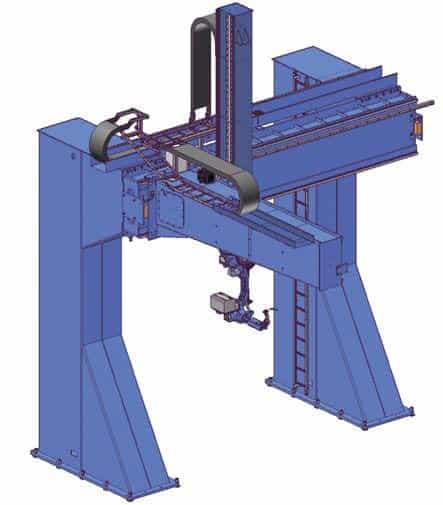

– gantry system: YASKAWA MOTOMAN TSG-06 XYZ

– welding machine: FRONIUS TransPuls Synergic 5000

– wire feeder: YASKAWA MOTOMAN SWFU

– auxiliary wire feeder: YASKAWA MOTOMAN HWFU

– operating station: TSC-B

– cable set: BINZEL

The YASKAWA MOTOMAN UP6-A00 compact industrial robot is distinguished by its fast working speed and robust arm with a reach of 1373 mm and a load capacity of 6 kg. The high axial speed, combined with its small size and weight, guarantees fast handling of any type of workpiece even in hard-to-reach areas. The welding robot is equipped with a very useful collision avoidance function and a YASKAWA MOTOMAN XRC controller to control the machine.

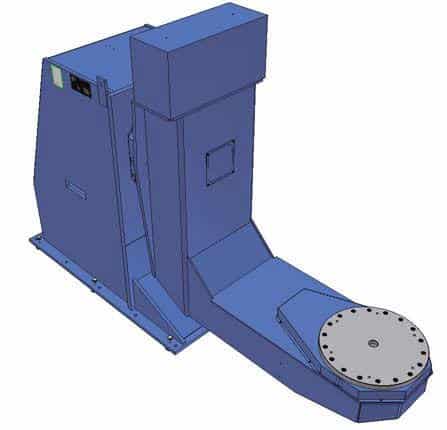

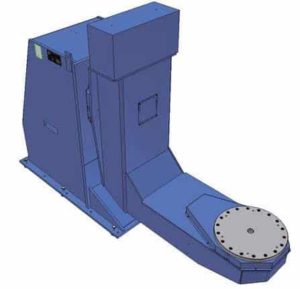

The welding cell is also equipped with a YASKAWA MOTOMAN MT1-3000-S2X positioner intended to help find the optimum position even for complex workpieces. Requiring a small amount of space, the solidly constructed design with an ‘L’ arm can withstand loads up to a maximum of 3000 kg. The single-station servo motor-controlled tilt-rotary positioner allows synchronisation of the X,Y axis with the robot’s movements.

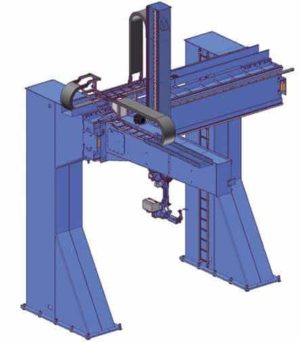

The applied YASKAWA MOTOMAN TSG-06 XYZ gantry system ensures reliable, accurate and economical production of large welded parts. Servo-driven X,Y,Z axis traverse

track system with feed rates of 4900 (X axis), 1800 (Y axis), 1200 mm (Z axis) have been fully integrated into the robot controller, increasing the robot’s working range.

Technical specifications of the YASKAWA MOTOMAN UP6-A00 robot

- controller: YASKAWA MOTOMAN XRC

- number of axes: 6

- arm reach: 1373 mm

- maximum payload: 6 kg

- positioning repeatability: ± 0.08 mm

- axis movement range

- axis motion speed

- machine weight: 130 kg

S axis: ± 170°

L axis: +155° / -90°

U axis: +190° / -170°

R axis: ± 180°

B axis: ± 135°

T axis: ± 360°

S axis: 140°/s

L axis: 160°/s

U axis: 170°/s

R axis: 335°/s

B axis: 335°/s

T axis: 500°/s

Technical specifications of YASKAWA MOTOMAN MT1-3000-S2X positioner

- number of axes: 2 (X, Y)

- maximum payload: 3000 kg

- X axis torque (dynamic): 17350 Nm

- X-axis torque (static): 13880 Nm

- maximum X axis orbital speed: 1.9 rpm

- maximum X axis offset: 462 mm

- X-axis range of motion: ± 225°

- Y-axis torque (dynamic): 12070 Nm

- Y-axis torque (static): 9650 Nm

- maximum Y-axis orbital speed: 2.7 rpm

- maximum Y-axis offset: 321 mm

- Y axis range of motion: ± 360°

- welding capacity (100%): 2x 350 A

- welding capacity (60%): 2x 460 A

- machine weight: 5600 kg

Technical data of the YASKAWA MOTOMAN TSG-06 XYZ gantry system

- number of servo-powered axes: 3

- AC servo motors: YASKAWA 1.3 kW (3 pcs.)

- feed rates in the X/Y/Z axis: 4900/1800/1200 mm

- feed speeds in the X/Y/Z axis: 28.8/28.8/10 m/min

- repetition accuracy: ± 0.5 mm

- machine weight: 2400 kg

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe