KUKA KR 500 R2830 MT industrial robot built in 2014 in Germany is mainly used for precision milling of workpieces. The robust arm design made of light metals and cast iron, combined with reinforced gears, provide high overload resistance and a high lifting capacity of up to 500 kg. During its 5-year service life, the KUKA KR 500 FORTEC milling robot has worked only 40 hours.

The machine has a 6-axis articulated arm kinematic system with components driven by AC actuators. This solution enables excellent dynamics and high process reliability. In order to significantly increase productivity and efficiency, both the robot and the KUKA KP1-V1000 rotary positioner with a load capacity of 1t are controlled by a KUKA KR C4 controller with many useful functions and programmes. The total weight of the machine is 2440kg.

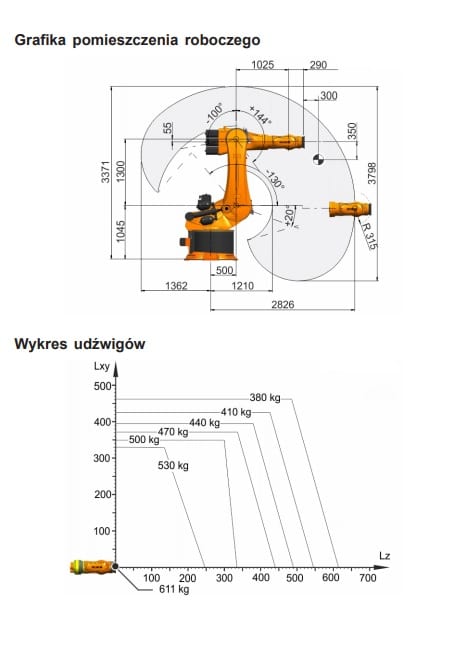

Technical specifications of the KUKA KR500 R2830 MT robot

- number of axes: 6

- arm reach: 2826 mm

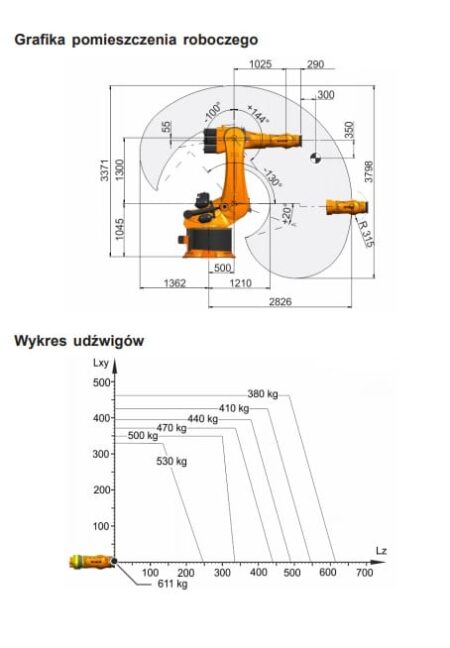

- payload: 500 kg

- total payload: 661 kg

- motion range of axes

- movement speed of axes

- position repeat accuracy: ± 0.08 mm

- load capacity of rotary positioner: 1000 kg

- operating hours: 40 h

- permissible inclination angle: ≤ 5°

- installation: floor

- space requirement: 1050 x 1050 mm

- ambient temperature: 10-55°C

- noise level: <75 dB(A)

- weight of controller: 149 kg

- weight of positioner: 380 kg

- weight of machine: 2440 kg

A1 axis: ± 185°

A2 axis: -130° / 20°

A3 axis: -100° / 144°

A4 axis: ± 350°

A5 axis: ± 120°

A6 axis: ± 350°

A1 axis: 45°/s

A2 axis: 45°/s

A3 axis: 45°/s

A4 axis: 90°/s

A5 axis: 83°/s

A6 axis: 130°/s

Equipment of the KUKA KR500 R2830 Machine Tool articulated robot

- controller: KUKA KR C4

- milling spindle 1C60/67DDBPER32

- 1-axis rotary positioner: KUKA KP1-V1000

- robot base: KUKA

- cabinet with modules safety SICK

- inverter: LG 7.50kW-3F (SV075iG5A-4)

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe